TROUBLE SHOOTING

CAUTION: ELECTRIC SHOCK HAZARD

Live electrical circuits are exposed during troubleshooting procedures

CAUTION: BURN HAZARD Equipment surfaces will be hot during troubleshooting procedures

B. TEMPERATURE CHECKS

1. Desired baking temperature is 390ºF ±5ºF (200ºC ±3ºC).

2. Turn the power switch ON and allow the Waffle Baker to heat for a minimum of 30 minutes. Insert a pyrometer of known accuracy betwen the grids and allow the readings to stabilize.

3. Temperature may be adjusted by removing the back panel,

and turning the dial on the temp controller: CW to decrease temperature; CCW to increase temperature.

NOTE: Manufacturer’s calibration point (390ºF) is indicated by a black dot on the face of the dial.

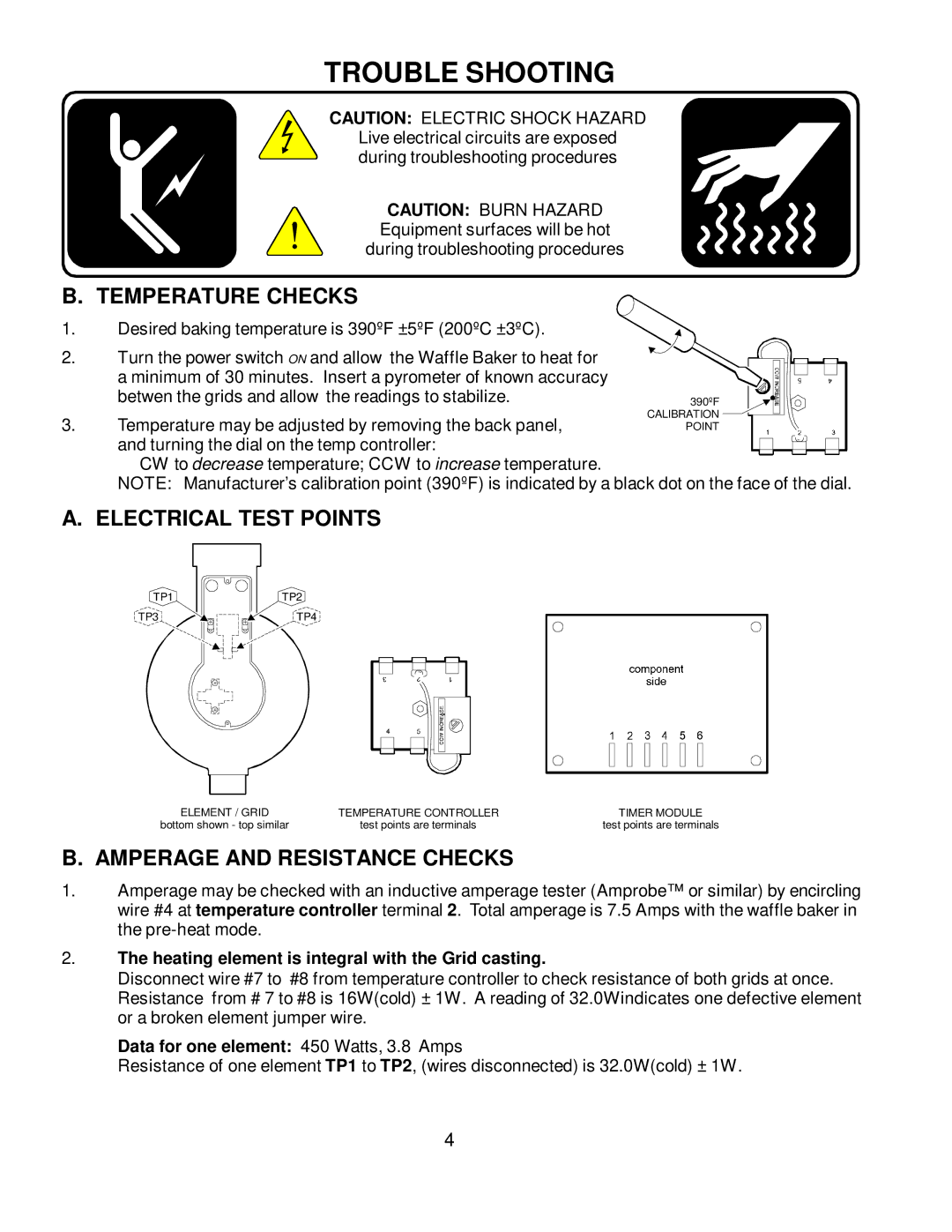

A. ELECTRICAL TEST POINTS

TP1

![]() TP3

TP3 ![]()

TP2

![]() TP4

TP4 ![]()

ELEMENT / GRID | TEMPERATURE CONTROLLER | TIMER MODULE |

bottom shown - top similar | test points are terminals | test points are terminals |

B. AMPERAGE AND RESISTANCE CHECKS

1.Amperage may be checked with an inductive amperage tester (Amprobe™ or similar) by encircling wire #4 at temperature controller terminal 2. Total amperage is 7.5 Amps with the waffle baker in the

2.The heating element is integral with the Grid casting.

Disconnect wire #7 to #8 from temperature controller to check resistance of both grids at once. Resistance from # 7 to #8 is 16Ω (cold) ± 1Ω . A reading of 32.0Ω indicates one defective element or a broken element jumper wire.

Data for one element: 450 Watts, 3.8 Amps

Resistance of one element TP1 to TP2, (wires disconnected) is 32.0Ω (cold) ± 1Ω .

4