Injury Hazard

To eliminate the risk of burns or fire, avoid installing cabinet storage above the cooking surface. If cabinets are already installed, avoid the use of cabinets while cooktop is in use.

Reaching over a heated cooking surface could result in a serious burn.

Use two or more people to move and install downdraft vent.

Failure to follow these instructions can result in back or other injury.

It is the customer’s responsibility:

To contact a qualified electrical installer. To assure that electrical installation is adequate and in conformance with National Electrical Code, ANSRNFPA 70 - latest edition’, and local codes and ordinances.

Electrical Shock Hazard

Take special care when drilling holes into the wall for venting or electrical wiring. Electrical wires may be concealed behind the wall covering.

Do Not use this downdraft vent with any solid state fan speed control device.

Failure to follow these instructions can result in death. fire or electrical shock.

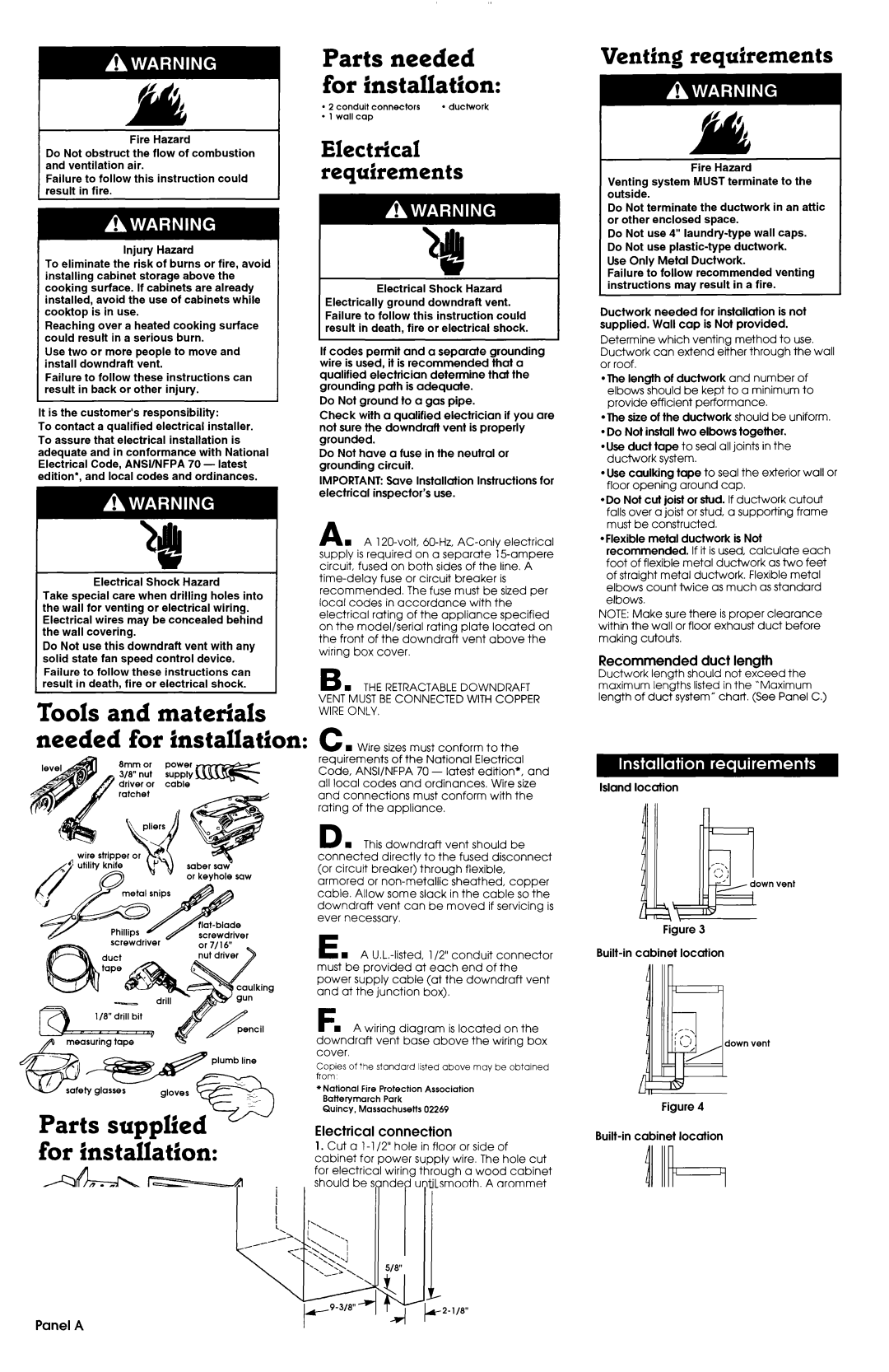

Tools and materials needed for installation:

8mm or

3/a'!nut

driver or cable ratchet

’ ’ orkevholesaw

screwdriver

‘I

L

@safety glasses

Parts supplied v for installation:

l | 2 | end | caps | l | 1 bag | of | fasteners |

l | 2 | lower | support legs | l | I metal | cover |

l | 2 | overcounter | l | 1 backdraft | damper |

| | mounting brackets | l | literature | package |

l2 undercounter mounting brackets

Panel B

I | | | a4 |

| | |

| | | rcc |

/ | . | Electrical. | Shock Hazard |

Electrically | ground | downdraft vent. |

Failure to follow this mstructron could result in death, fire or electrical shock.

If codes permit and a separqte grounding

wire is used, it is recommended that a qualified electrician determine that the grounding path is adequate.

Do Not ground to a gas pipe.

Check with a qualified electrician if you are not sure the downdraft vent is properly grounded.

Do Not have a fuse in the neutral or grounding circuit.

IMPORTANT: Save lnstallcrtion Instructions for electrical inspector’s use.

A w A 120-volt, 60-Hz, AC-only electrical supply is required on a separate 15ampere circuit, fused on both sides of the line. A time-delay fuse or circuit breaker is

recommended. The fuse must be sized per

local codes in accordance with the electrical rating of the appliance specified on the model/serial rating plate located on the front of the downdraft vent above the wiring box cover.

B n THE RETRACTABLE DOWNDRAFT VENT MUST BE CONNECTED WITH COPPER WIRE ONLY.

C n Wire sizes must conform to the requirements of the National Electrical Code, ANSI/NFPA 70 - latest edition*, and all local codes and ordinances. Wire size and connections must conform with the rating of the appliance.

D n This downdraft vent should be connected directly to the fused disconnect (or circuit breaker) through flexible, armored or non-metallic sheathed, copper cable. Allow some slack in the cable so the downdraft vent can be moved if servicing is ever necessary.

E n A U.L.-listed, l/2” conduit connector must be provided at each end of the power supply cable (at the downdraft vent and at the junction box).

Fn A wiring diagram is located on the downdraft vent base above the wiring box cover.

Copies of the standard listed above may be obtained from.

*National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

Electrical connection

1. Cut a l-l /2” hole in floor or side of

cabinet for power supply wire. The hole cut for electrical wiring through a wood cabinet should be sanded until smooth. A grommet (Part No. 302797) must cover the hole cut for the electrical wiring through a metal cabinet.

2.Run flexible armored or nonmetallic sheathed copper cable from fused disconnect circuit breaker or junction box through the cabinet hole to the downdraft vent location.

3.See installation steps to connect power supply cable to downdraft vent.

Do Not terminate the ductwork in an attic or other enclosed space.

Do Not use 4” laundry-type wall caps. Do Not use plastic-type ductwork.

Use Only Metal Ductwork.

Failure to follow recommended venting instructions may result in a fire.

Ductwork needed for installation is not supplied. Wall cap is Not provided.

Determine which venting method to use. Ductwork can extend either through the wall or roof.

*The length of ductwork and number of elbows should be kept to a minimum to provide efficient performance.

*The size of the ductwork should be uniform. l Do Not insfall two elbows together.

*Use duct tape to seal all joints in the ductwork system.

l Use caulking tape to seal the exterior wall or floor opening around cap.

*Do Not cut joist or stud. If ductwork cutout falls over a joist or stud, a supporting frame must be constructed.

*Flexible metal ductwork is Not

recommended. If it is used, calculate each foot of flexible metal ductwork as two feet of straight metal ductwork. Flexible metal elbows count twice as much as standard elbows.

NOTE: Make sure there is proper clearance within the wall or floor exhaust duct before making cutouts,

Recommended duct length

Ductwork length should not exceed the maximum lengths listed in the ‘Maximum length of duct system” chart. (See Panel C.)

Island location

Figure 3

Built-in cabinet location

own vent

Figure 4

Built-in cabinet location

Figure 5