Endurance | Page 21 |

|

|

|

|

jacket, remove the four (4) long screws that secure the top and bottom pans. Remove the air vent and the top pan. Remove the insulation retainer and the coil cover insulation. Clean the boiler coil with a wire brush and vacuum debris from the combustion chamber (avoid hitting the ignitor or the flame sensor with the brush or vacuum hose because they are fragile).

After cleaning, assemble the parts in the reverse order, open isolation valves and bleed air from the boiler and the system. Follow the lighting instructions and start the boiler. Check operation.

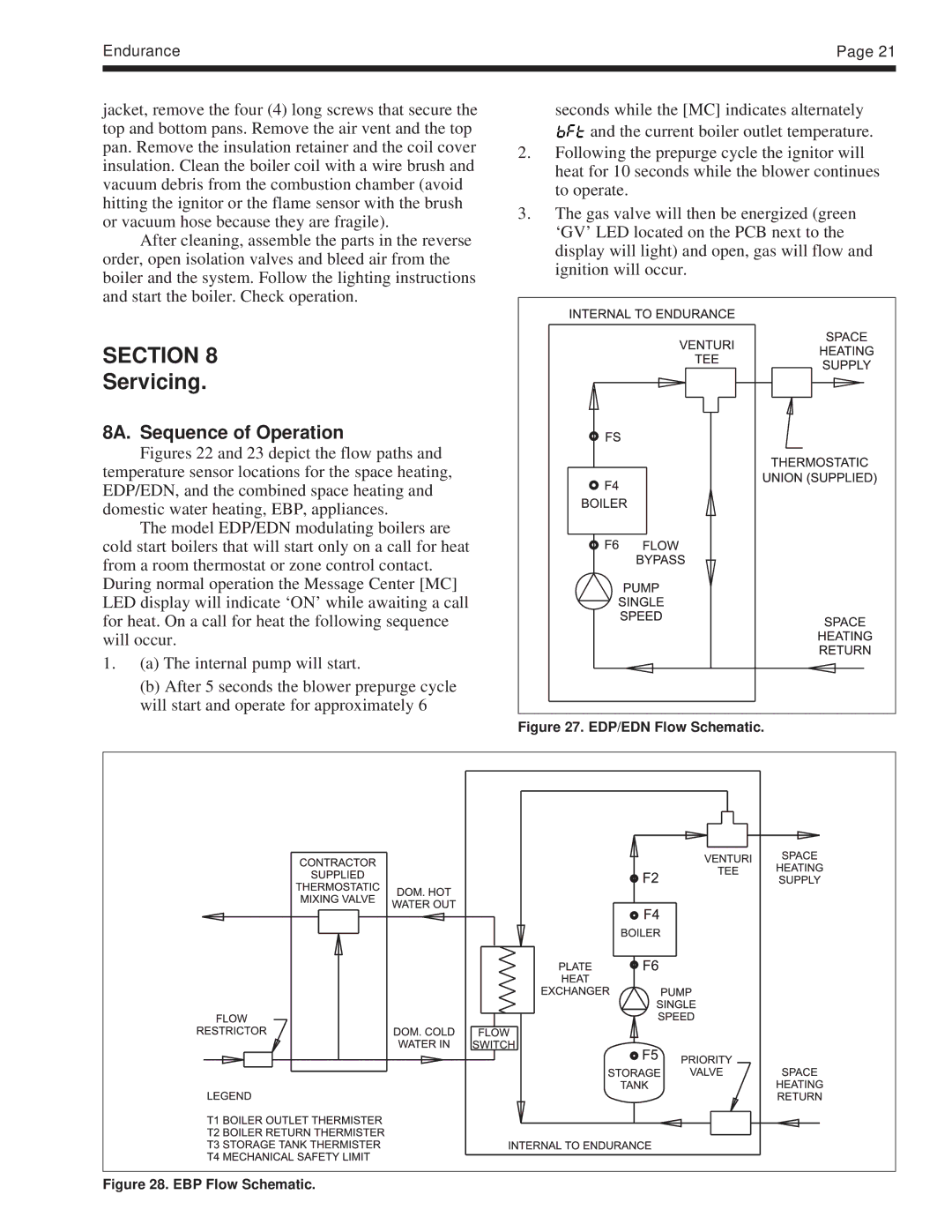

seconds while the [MC] indicates alternately ![]()

![]() and the current boiler outlet temperature.

and the current boiler outlet temperature.

2.Following the prepurge cycle the ignitor will heat for 10 seconds while the blower continues to operate.

3.The gas valve will then be energized (green ‘GV’ LED located on the PCB next to the display will light) and open, gas will flow and ignition will occur.