Page 4 | LAARS HEATING SYSTEMS |

|

|

|

|

2.The CSA standard C22.1 “Canadian Electrical Code - Part 1” and local codes.

All vent installations must be made in accordance with:

1.Part 7, Venting of Equipment of the National Fuel Gas Code, ANSI 223.1 latest edition, or applicable provisions of the local building codes or

2.CAN/CGA B149.

When required by the jurisdiction authority, the installations must conform to the American Society of Mechanical Engineers' Safety Code for Controls and Safety Devices for Automatically Fired Boilers, No.

1C. Unpacking the Appliance

Remove all packing and tie down materials. Make immediate claims (to the carrier) if the appliance and its packaging are damaged.

1D. Locating the Appliance

The appliance is designed for installation on combustible flooring, in alcoves, basements, closets, or utility rooms. It must not be installed on carpeting.

IF INSTALLED IN A FINISHED AREA, PROVISION SHOULD BE MADE FOR DRAINAGE OF ANY ACCIDENTAL SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with regard to venting dimensions, convenient access to piping, and accessibility for service and cleaning.

The boiler shall be installed so that the gas ignition system components are protected from water (dripping, spraying, rain, etc.) during appliance operation or service (circulator replacement, control replacement, etc.).

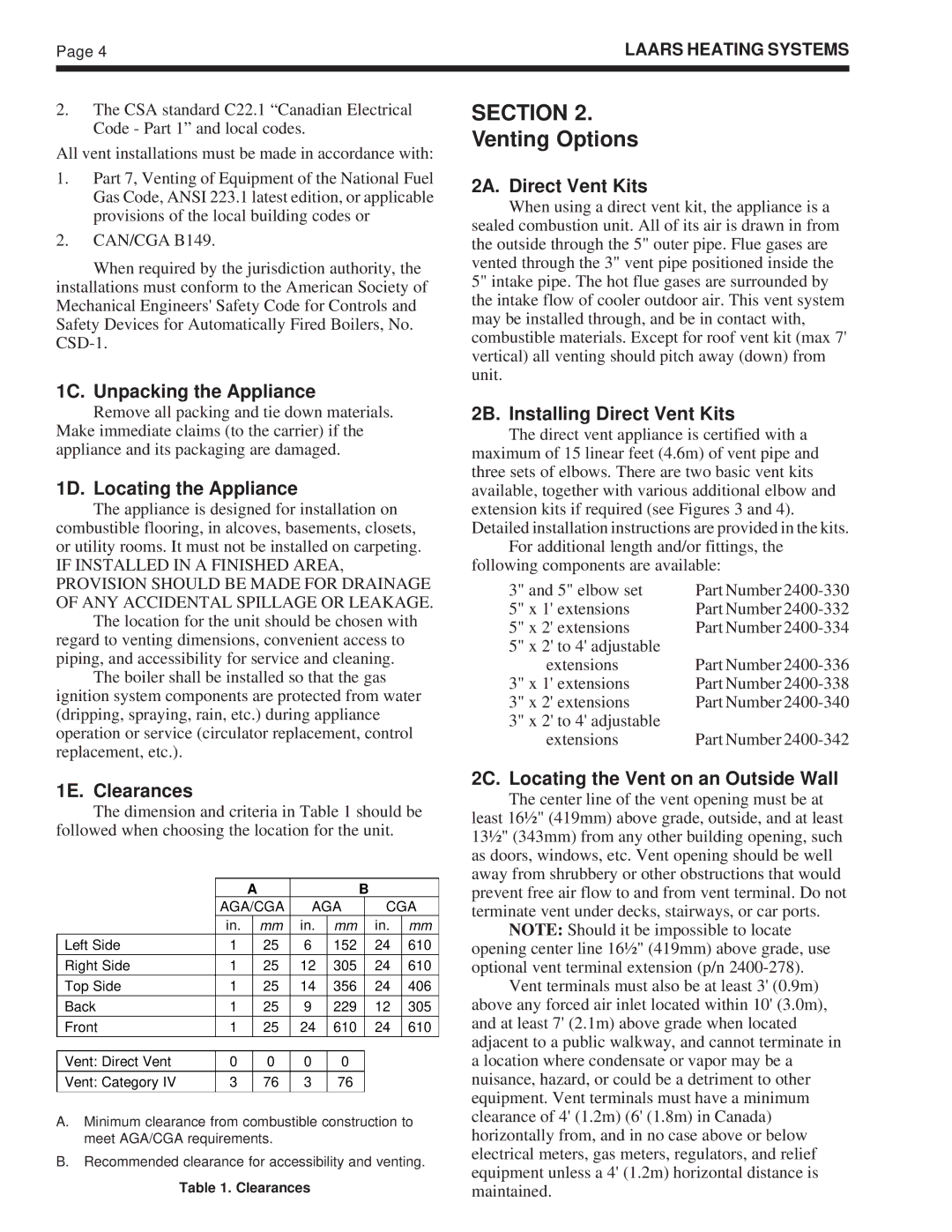

1E. Clearances

The dimension and criteria in Table 1 should be followed when choosing the location for the unit.

|

| A |

|

| B |

| ||

| AGA/CGA | AGA |

| CGA | ||||

| in. |

| mm | in. | mm |

| in. | mm |

Left Side | 1 |

| 25 | 6 | 152 |

| 24 | 610 |

Right Side | 1 |

| 25 | 12 | 305 |

| 24 | 610 |

Top Side | 1 |

| 25 | 14 | 356 |

| 24 | 406 |

Back | 1 |

| 25 | 9 | 229 |

| 12 | 305 |

Front | 1 |

| 25 | 24 | 610 |

| 24 | 610 |

|

|

|

|

|

|

|

| |

Vent: Direct Vent | 0 |

| 0 | 0 | 0 |

|

|

|

Vent: Category IV | 3 |

| 76 | 3 | 76 |

|

|

|

|

|

|

|

|

|

|

|

|

A.Minimum clearance from combustible construction to meet AGA/CGA requirements.

B.Recommended clearance for accessibility and venting.

Table 1. Clearances

SECTION 2.

Venting Options

2A. Direct Vent Kits

When using a direct vent kit, the appliance is a sealed combustion unit. All of its air is drawn in from the outside through the 5" outer pipe. Flue gases are vented through the 3" vent pipe positioned inside the 5" intake pipe. The hot flue gases are surrounded by the intake flow of cooler outdoor air. This vent system may be installed through, and be in contact with, combustible materials. Except for roof vent kit (max 7' vertical) all venting should pitch away (down) from unit.

2B. Installing Direct Vent Kits

The direct vent appliance is certified with a maximum of 15 linear feet (4.6m) of vent pipe and three sets of elbows. There are two basic vent kits available, together with various additional elbow and extension kits if required (see Figures 3 and 4). Detailed installation instructions are provided in the kits.

For additional length and/or fittings, the following components are available:

3" and 5" elbow set | Part Number |

5" x 1' extensions | Part Number |

5" x 2' extensions | Part Number |

5" x 2' to 4' adjustable |

|

extensions | Part Number |

3" x 1' extensions | Part Number |

3" x 2' extensions | Part Number |

3" x 2' to 4' adjustable |

|

extensions | Part Number |

2C. Locating the Vent on an Outside Wall

The center line of the vent opening must be at least 16½" (419mm) above grade, outside, and at least 13½" (343mm) from any other building opening, such as doors, windows, etc. Vent opening should be well away from shrubbery or other obstructions that would prevent free air flow to and from vent terminal. Do not terminate vent under decks, stairways, or car ports.

NOTE: Should it be impossible to locate opening center line 16½" (419mm) above grade, use optional vent terminal extension (p/n

Vent terminals must also be at least 3' (0.9m) above any forced air inlet located within 10' (3.0m), and at least 7' (2.1m) above grade when located adjacent to a public walkway, and cannot terminate in a location where condensate or vapor may be a nuisance, hazard, or could be a detriment to other equipment. Vent terminals must have a minimum clearance of 4' (1.2m) (6' (1.8m) in Canada) horizontally from, and in no case above or below electrical meters, gas meters, regulators, and relief equipment unless a 4' (1.2m) horizontal distance is maintained.