WaterRequirements

The filtration system must be connected to a cold water supply line providing

Review the water application guideline chart

below to determine if your water meets the standards necessary to use this water filtration system.

| DO NOT use filtration system if water is |

|

| 1 | |||||

| microbiologically | unsafe or water quality |

|

| |||||

| is unknown. Pretreat water that exceeds |

|

| ||||||

| limits for hardness, iron, manganese, and hydro- | ||||||||

I | gen | sulfide. |

|

|

|

|

| ||

Failure to | follow | these instructions | could result | ||||||

| in personal | injury. |

|

|

|

|

| ||

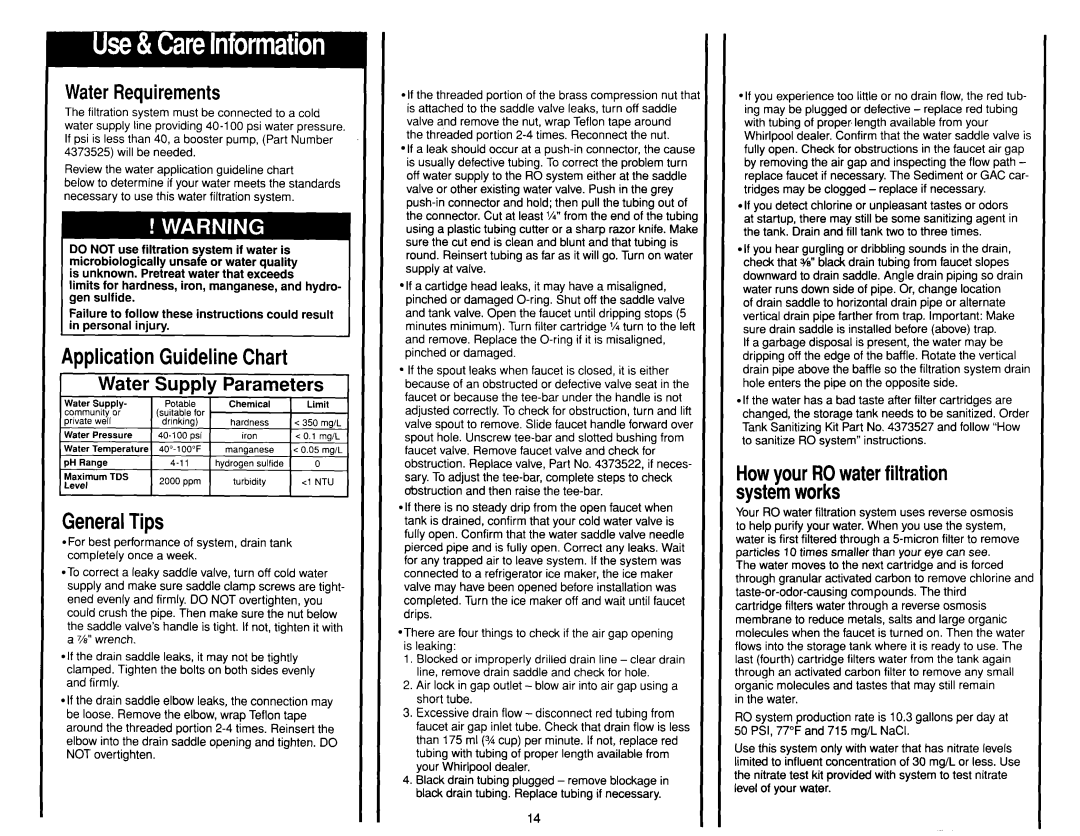

Application GuidelineChart |

|

|

| ||||||

|

| Water Supply | Parameters |

|

| ||||

| Water | Supply- |

| Potable | Chemical | Limit |

| ||

| community or |

| (suitable for |

|

|

|

|

| |

| private | well |

| drinking) | hardness | < 350 | mg/L | ||

| Water | Pressure |

| iron |

| < 0.1 | mg/L |

| |

| Water | Temperature | 40”.100°F | manganese | < 0.05 | mg/L | |||

| pH Range |

| hydrogen | sulfide | 0 |

|

| ||

| pt;;nurn | TDS | 2000 ppm | turbidity | <I NTU |

| |||

|

|

|

|

| |||||

GeneralTips

*For best performance of system, drain tank completely once a week.

l If the drain saddle leaks, it may not be tightly clamped. Tighten the bolts on both sides evenly and firmly.

l If the drain saddle elbow leaks, the connection may be loose. Remove the elbow, wrap Teflon tape around the threaded portion

*If the threaded portion of the brass compression nut tha is attached to the saddle valve leaks, turn off saddle valve and remove the nut, wrap Teflon tape around

the threaded portion

*If a leak should occur at a

l If a cartidge head leaks, it may have a misaligned, pinched or damaged

lIf the spout leaks when faucet is closed, it is either because of an obstructed or defective valve seat in the faucet or because the

l If there is no steady drip from the open faucet when tank is drained, confirm that your cold water valve is fully open. Confirm that the water saddle valve needle pierced pipe and is fully open. Correct any leaks. Wait for any trapped air to leave system. If the system was connected to a refrigerator ice maker, the ice maker valve may have been opened before installation was completed. Turn the ice maker off and wait until faucet drips.

*There are four things to check if the air gap opening is leaking:

1.Blocked or improperly drilled drain line - clear drain line, remove drain saddle and check for hole.

2.Air lock in gap

3.Excessive drain flow - disconnect red tubing from faucet air gap inlet tube. Check that drain flow is less than 175 ml (% cup) per minute. If not, replace red tubing with tubing of proper length available from your Whirlpool dealer.

4.Black drain tubing plugged - remove blockage in black drain tubing. Replace tubing if necessary.

*If you experience too little or no drain flow, the red tub- ing may be plugged or defective - replace red tubing with tubing of proper length available from your Whirlpool dealer. Confirm that the water saddle valve is fully open. Check for obstructions in the faucet air gap by removing the air gap and inspecting the flow path - replace faucet if necessary. The Sediment or GAC car- tridges may be clogged - replace if necessary.

l If you detect chlorine or unpleasant tastes or odors at startup, there may still be some sanitizing agent in the tank. Drain and fill tank two to three times.

*If you hear gurgling or dribbling sounds in the drain, check that 3/g”black drain tubing from faucet slopes downward to drain saddle. Angle drain piping so drain water runs down side of pipe. Or, change location

of drain saddle to horizontal drain pipe or alternate vertical drain pipe farther from trap. Important: Make sure drain saddle is installed before (above) trap.

If a garbage disposal is present, the water may be dripping off the edge of the baffle. Rotate the vertical drain pipe above the baffle so the filtration system drain hole enters the pipe on the opposite side.

l If the water has a bad taste after filter cartridges are changed, the storage tank needs to be sanitized. Order Tank Sanitizing Kit Part No. 4373527 and follow “How to sanitize RO system” instructions.

HowyourROwaterfiltration systeinworks

Your RO water filtration system uses reverse osmosis to help purify your water. When you use the system, water is first filtered through a

The water moves to the next cartridge and is forced through granular activated carbon to remove chlorine and

cartridge filters water through a reverse osmosis membrane to reduce metals, salts and large organic molecules when the faucet is turned on. Then the water flows into the storage tank where it is ready to use. The last (fourth) cartridge filters water from the tank again through an activated carbon filter to remove any small organic molecules and tastes that may still remain

in the water.

RO system production rate is 10.3 gallons per day at 50 PSI, 77°F and 715 mg/L NaCI.

Use this system only with water that has nitrate levels limited to influent concentration of 30 mg/L or less. Use the nitrate test kit provided with system to test nitrate level of your water.

14