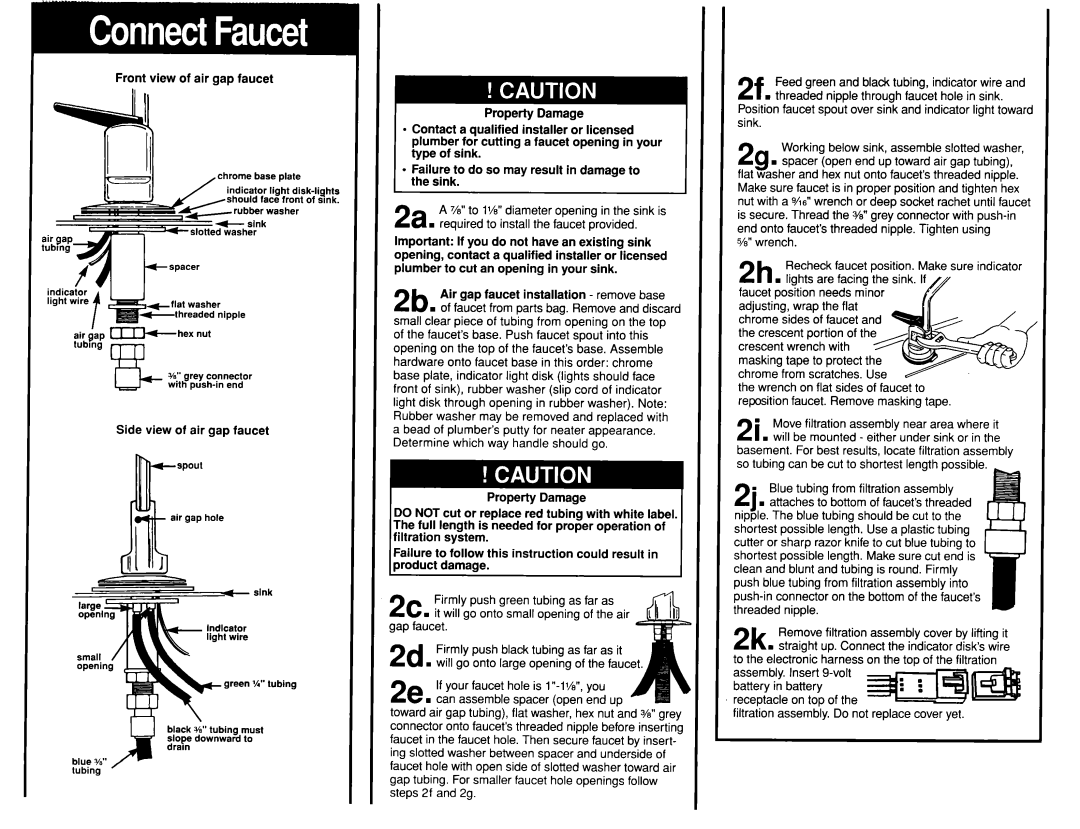

Front view of air gap faucet

_ chrome base elate

indicator | - |

|

|

light wire |

|

|

|

| t |

|

|

;fby;; | Fhex |

| nut |

| Is- | %” | grey connector |

| with | ||

|

|

| |

Side view of air gap faucet

spout

kair gap hole

slnk

%” tubing

black %” tubing must ;lor; downward to

blue %” tubing

Property Damage

l Contact a qualified installer or licensed plumber for cutting a faucet opening in your type of sink.

l F!;IIwJ~ do so may result in damage to

2a A 741”to 1%” diameter opening in the sink is

. required to install the faucet provided.

Important: If you do not have an existing sink opening, contact a qualified installer or licensed plumber to cut an opening in your sink.

2b Air gap faucet installation - remove base

. of faucet from parts bag. Remove and discard small clear piece of tubing from opening on the top of the faucet’s base. Push faucet spout into this opening on the top of the faucet’s base. Assemble hardware onto faucet base in this order: chrome base plate, indicator light disk (lights should face front of sink), rubber washer (slip cord of indicator light disk through opening in rubber washer). Note: Rubber washer may be removed and replaced with a bead of plumber’s putty for neater appearance. Determine which way handle should go.

Property Damage

DO NOT cut or replace red tubing with white label. The full length is needed for proper operation of filtration system.

Failure to follow this instruction could result in product damage.

2c Firmly push green tubing as far as

. it will go onto small opening of the air gap faucet.

2d Firmly push black tubing as far as it

. will go onto large opening of the faucet.

2e If your faucet hole is

H can assemble spacer (open end up

toward air gap tubing), flat washer, hex nut and 3/e”grey connector onto faucet’s threaded nipple before inserting faucet in the faucet hole. Then secure faucet by insert- ing slotted washer between spacer and underside of faucet hole with open side of slotted washer toward air gap tubing. For smaller faucet hole openings follow steps 2f and 29.

2f Feed green and black tubing, indicator wire and n threaded nipple through faucet hole in sink.

Position faucet spout over sink and indicator light toward sink.

29Working below sink, assemble slotted washer,

. spacer (open end up toward air gap tubing), flat washer and hex nut onto faucet’s threaded nipple. Make sure faucet is in proper position and tighten hex nut with a %6” wrench or deep socket rachet until faucet is secure. Thread the Y811grey connector with

76” wrench.

2h Recheck faucet position. Make sure indicator

. lights are facing the sink. I faucet position needs minor adjusting, wrap the flat

chrome sides of faucet the crescent portion of crescent wrench with masking tape to protect th chrome from scratches. Use

the wrench on flat sides of faucet to reposition faucet. Remove masking tape.

21. Move filtration assembly near area where it

. will be mounted - either under sink or in the basement. For best results, locate filtration assembly so tubing can be cut to shortest length possible.

Blue tubing from filtration assembly

. attaches to bottom of faucet’s threaded The blue tubino should be cut to the

shortest possible lengih. Use a plastic tubing cutter or sharp razor knife to cut blue tubing to

shortest possible length. Make sure cut end is 5 clean and blunt and tubing is round. Firmly

push blue tubing from filtration assembly into

2k Remove filtration assembly cover by liftirig it

. straight up. Connect the indicator disks wrre to the electronic harness on the too of the filtration assembly. Insert

battery in battery receptacle on top of the