PRESSURE REGULATOR

ADJUSTMENT

These controls are shipped from the factory with the regulator set as specified on the control label. Consult the appliance rating plate to ensure burner manifold pressure is as specified. If another outlet pressure is required, follow these steps.

NOTE

Natural

Single Stage Models - Outlet pressure can be ad- justed in the 2.5” to 5” range. The valve cannot be adjusted outside this range.

ADJUSTMENT

4. |

| ||

| from the low outlet pressure regulator adjust | ||

| tower (fig. 9) and turn screw clockwise ( | ) | |

| to increase pressure, or counterclockwise |

| |

| ( | ) to decrease pressure. Always adjust |

|

| regulator according to original equipment |

| |

| manufacture’s specifications listed on the ap- | ||

| pliance rating plate. Replace regulator cover |

| |

| screw. |

| |

5. |

| ||

| stage. |

| |

6. | Remove regulator cover screw from the single | ||

| stage or high outlet pressure regulator adjust | ||

| tower (fig. 9) and turn screw clockwise ( | ) | |

| to increase pressure, or counterclockwise |

| |

| ( | ) to decrease pressure. Always adjust |

|

| regulator according to original equipment |

| |

| manufacturer’s specifications listed on the |

| |

| appliance rating plate. Replace regulator cover | ||

| screw. |

| |

7. | Turn off all electrical power to the system. |

| |

8. | Remove manometer hose and fitting from |

| |

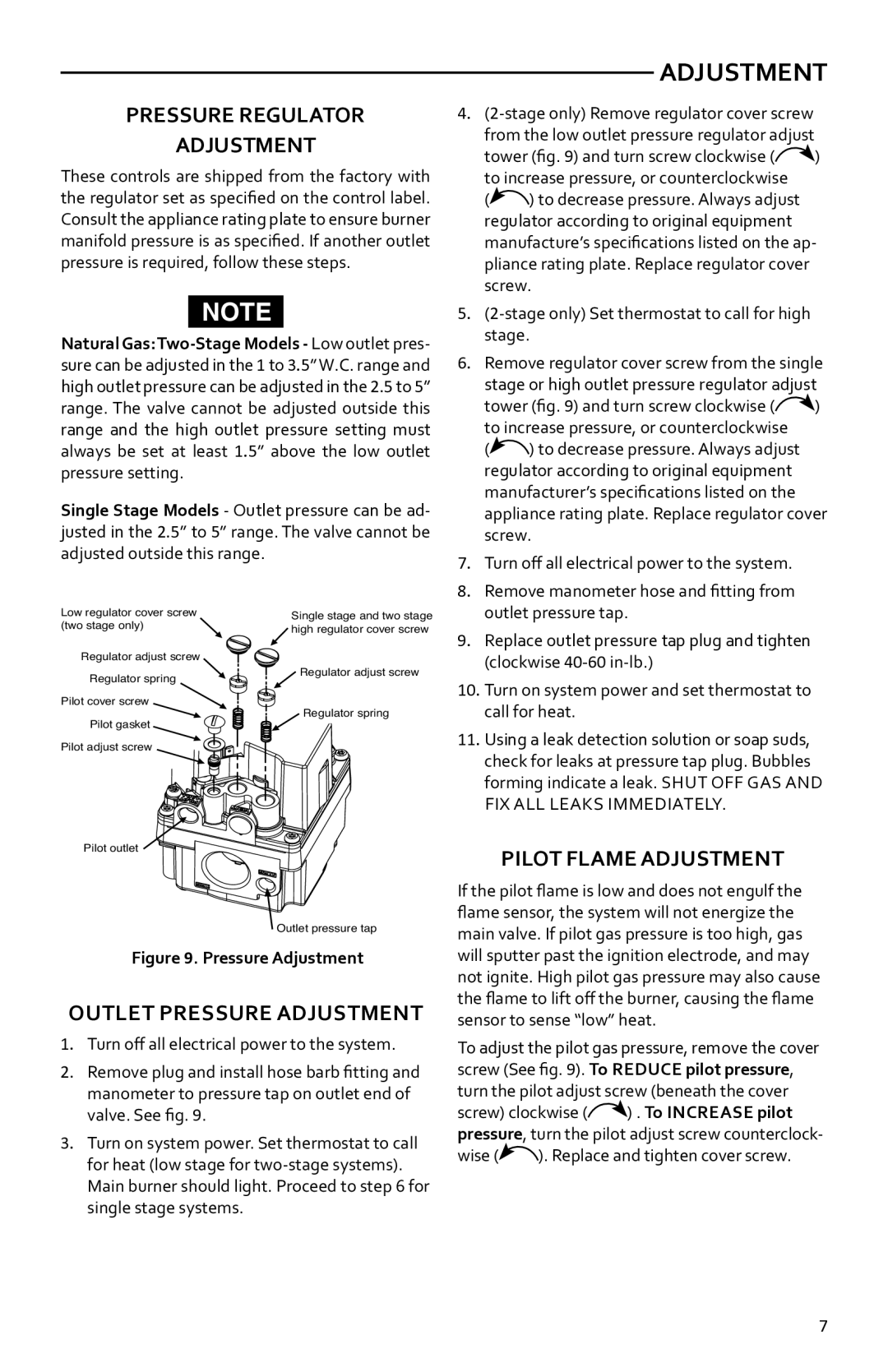

Low regulator cover screw (two stage only)![]()

Regulator adjust screw Regulator spring

Pilot cover screw Pilot gasket

Pilot adjust screw

Pilot outlet ![]()

Single stage and two stage high regulator cover screw

Regulator adjust screw

Regulator spring

![]() Outlet pressure tap

Outlet pressure tap

outlet pressure tap. |

9. Replace outlet pressure tap plug and tighten |

(clockwise |

10. Turn on system power and set thermostat to |

call for heat. |

11. Using a leak detection solution or soap suds, |

check for leaks at pressure tap plug. Bubbles |

forming indicate a leak. Shut off gas and |

Fix all leaks immediately. |

Pilot Flame Adjustment

If the pilot flame is low and does not engulf the flame sensor, the system will not energize the main valve. If pilot gas pressure is too high, gas

Figure 9. Pressure Adjustment

Outlet Pressure Adjustment

1.Turn off all electrical power to the system.

2.Remove plug and install hose barb fitting and manometer to pressure tap on outlet end of valve. See fig. 9.

3.Turn on system power. Set thermostat to call for heat (low stage for

will sputter past the ignition electrode, and may not ignite. High pilot gas pressure may also cause the flame to lift off the burner, causing the flame sensor to sense “low” heat.

To adjust the pilot gas pressure, remove the cover screw (See fig. 9). To reduce pilot pressure, turn the pilot adjust screw (beneath the cover

screw) clockwise (![]() ) . To Increase pilot pressure, turn the pilot adjust screw counterclock-

) . To Increase pilot pressure, turn the pilot adjust screw counterclock-

wise (![]() ). Replace and tighten cover screw.

). Replace and tighten cover screw.

7