Anti-Kickback Fingers

The

Infeed and Outfeed Roller Spring Tension

The infeed roller (B, Figure 23) and outfeed roller (E, Figure 23) are those parts of your planer that feed the stock while it is being planed. The infeed roller and the outfeed roller are under spring tension and this tension must be sufficient to feed the stock uniformly through the planer without slipping but should not be so tight that it causes damage to the board. The tension should be equal at both ends of each roller.

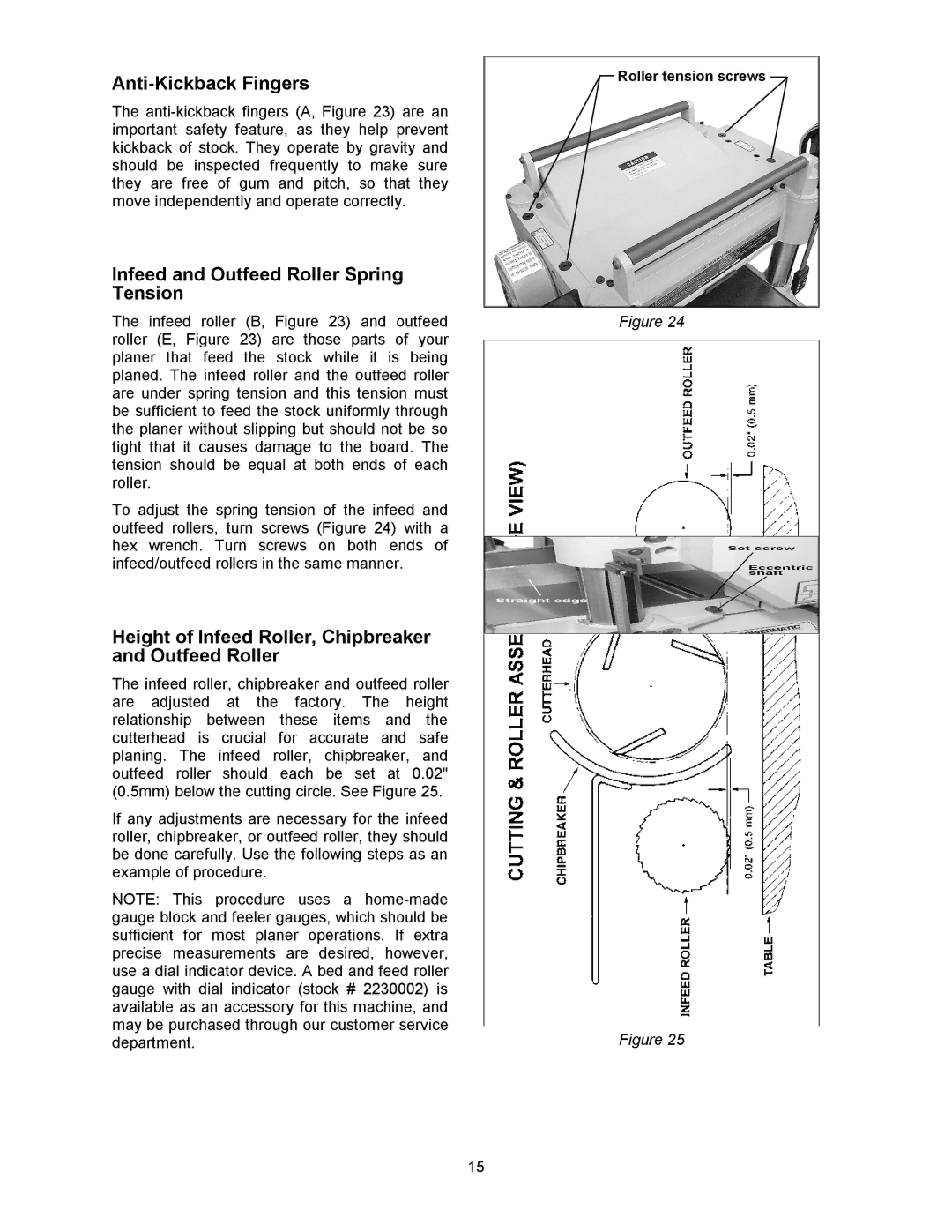

To adjust the spring tension of the infeed and outfeed rollers, turn screws (Figure 24) with a hex wrench. Turn screws on both ends of infeed/outfeed rollers in the same manner.

Height of Infeed Roller, Chipbreaker and Outfeed Roller

The infeed roller, chipbreaker and outfeed roller are adjusted at the factory. The height relationship between these items and the cutterhead is crucial for accurate and safe planing. The infeed roller, chipbreaker, and outfeed roller should each be set at 0.02" (0.5mm) below the cutting circle. See Figure 25.

If any adjustments are necessary for the infeed roller, chipbreaker, or outfeed roller, they should be done carefully. Use the following steps as an example of procedure.

NOTE: This procedure uses a

Figure 24

Figure 25

15