Changing abrasive discs (continued)

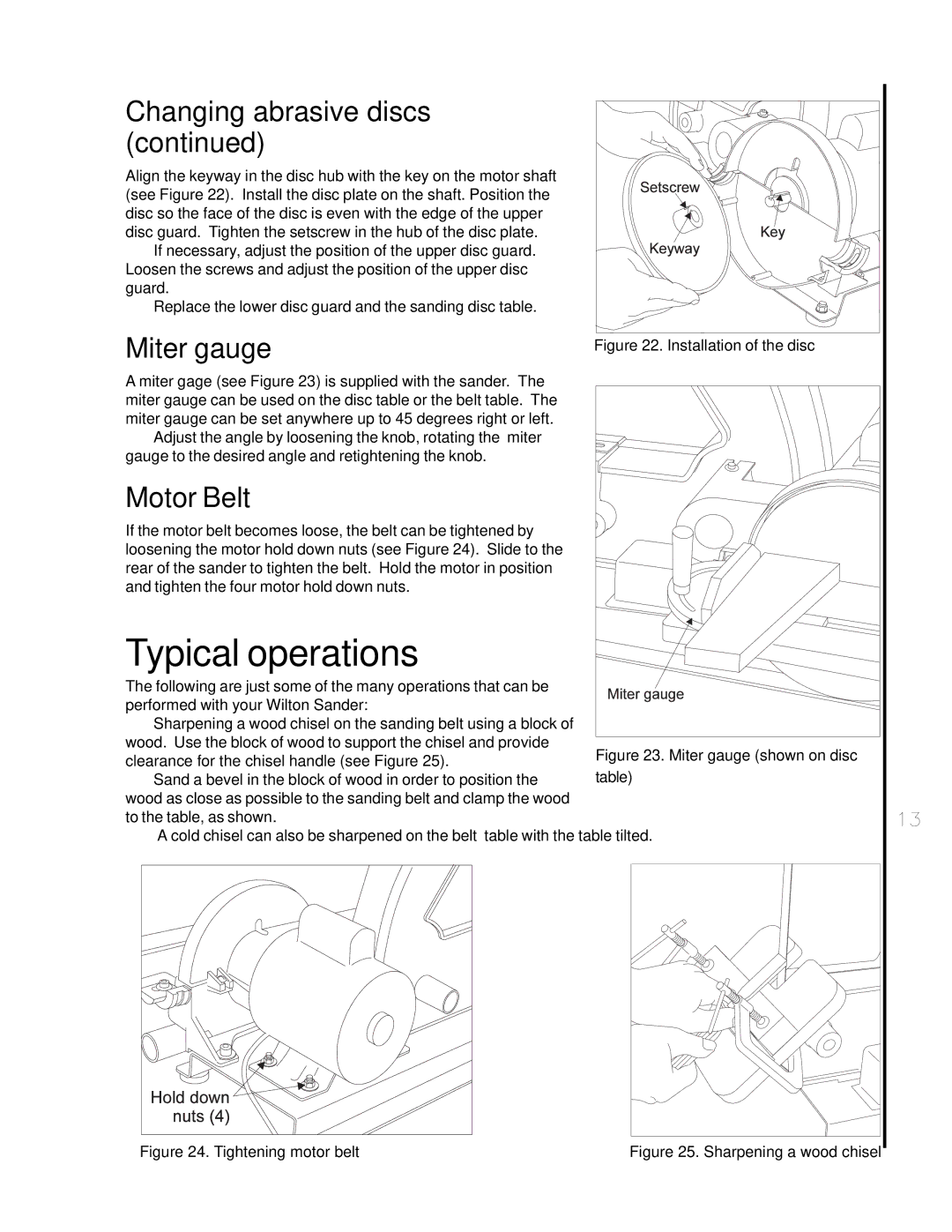

Align the keyway in the disc hub with the key on the motor shaft (see Figure 22). Install the disc plate on the shaft. Position the disc so the face of the disc is even with the edge of the upper disc guard. Tighten the setscrew in the hub of the disc plate.

If necessary, adjust the position of the upper disc guard. Loosen the screws and adjust the position of the upper disc guard.

Replace the lower disc guard and the sanding disc table.

Miter gauge | Figure 22. Installation of the disc |

| |

A miter gage (see Figure 23) is supplied with the sander. The |

|

miter gauge can be used on the disc table or the belt table. The |

|

miter gauge can be set anywhere up to 45 degrees right or left. |

|

Adjust the angle by loosening the knob, rotating the miter |

|

gauge to the desired angle and retightening the knob. |

|

Motor Belt |

|

If the motor belt becomes loose, the belt can be tightened by |

|

loosening the motor hold down nuts (see Figure 24). Slide to the |

|

rear of the sander to tighten the belt. Hold the motor in position |

|

and tighten the four motor hold down nuts. |

|

Typical operations

The following are just some of the many operations that can be |

| |

performed with your Wilton Sander: |

| |

Sharpening a wood chisel on the sanding belt using a block of |

| |

wood. Use the block of wood to support the chisel and provide | Figure 23. Miter gauge (shown on disc | |

clearance for the chisel handle (see Figure 25). | ||

table) | ||

Sand a bevel in the block of wood in order to position the | ||

wood as close as possible to the sanding belt and clamp the wood |

| |

to the table, as shown. |

|

A cold chisel can also be sharpened on the belt table with the table tilted.

Figure 24. Tightening motor belt | Figure 25. Sharpening a wood chisel |

13