Disc table adjustments

Adjusting the table angle

WARNING: When making adjustments, make sure the motor is discon- nected from the power source.

WARNING: To avoid trapping the work or fingers between the table and sanding disc, the table edge should be positioned a maximum of 1/16- inch from the sanding disc.

The disc table is positioned at 90 degrees to the sanding disc for most operations (see Figure 14). To check and see if the table is at 90 de- grees, place a square, on the table with one end of the square against the sanding disc. If an adjustment is necessary, loosen the cap screws and move table until it is at 90 degrees to the sanding disc. Tighten the screws to secure the table.

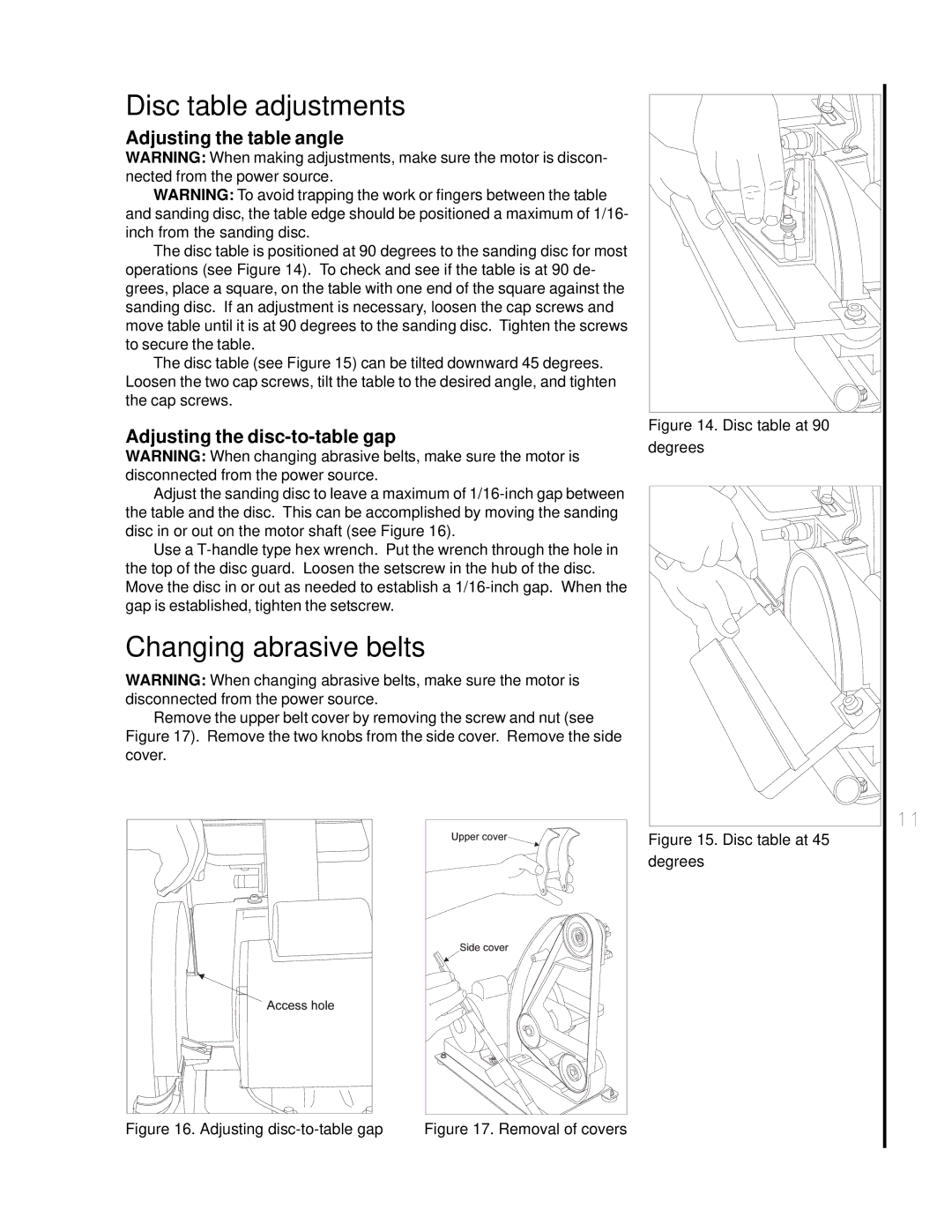

The disc table (see Figure 15) can be tilted downward 45 degrees. Loosen the two cap screws, tilt the table to the desired angle, and tighten the cap screws.

Adjusting the disc-to-table gap

WARNING: When changing abrasive belts, make sure the motor is disconnected from the power source.

Adjust the sanding disc to leave a maximum of

Use a

Changing abrasive belts

WARNING: When changing abrasive belts, make sure the motor is disconnected from the power source.

Remove the upper belt cover by removing the screw and nut (see

Figure 17). Remove the two knobs from the side cover. Remove the side cover.

Figure 14. Disc table at 90 degrees

Figure 15. Disc table at 45 degrees

11

Figure 16. Adjusting | Figure 17. Removal of covers |