18. All visitors should be kept at a safe distance from | removing starter keys. |

the work area. Make workshop completely safe | 19. Know the tool you are using its application, |

by using padlocks, master switches, or by | limitations, and potential hazards. |

General electrical cautions

This sander should be grounded in accordance with the National Electrical Code and local codes and ordinances. This work should be done by a qualified electrician. The sander should be grounded to protect the user from electrical shock.

WARNING: Do not connect the sander to a 240 volt power source. The sander motor requires 120 volts alternating current.

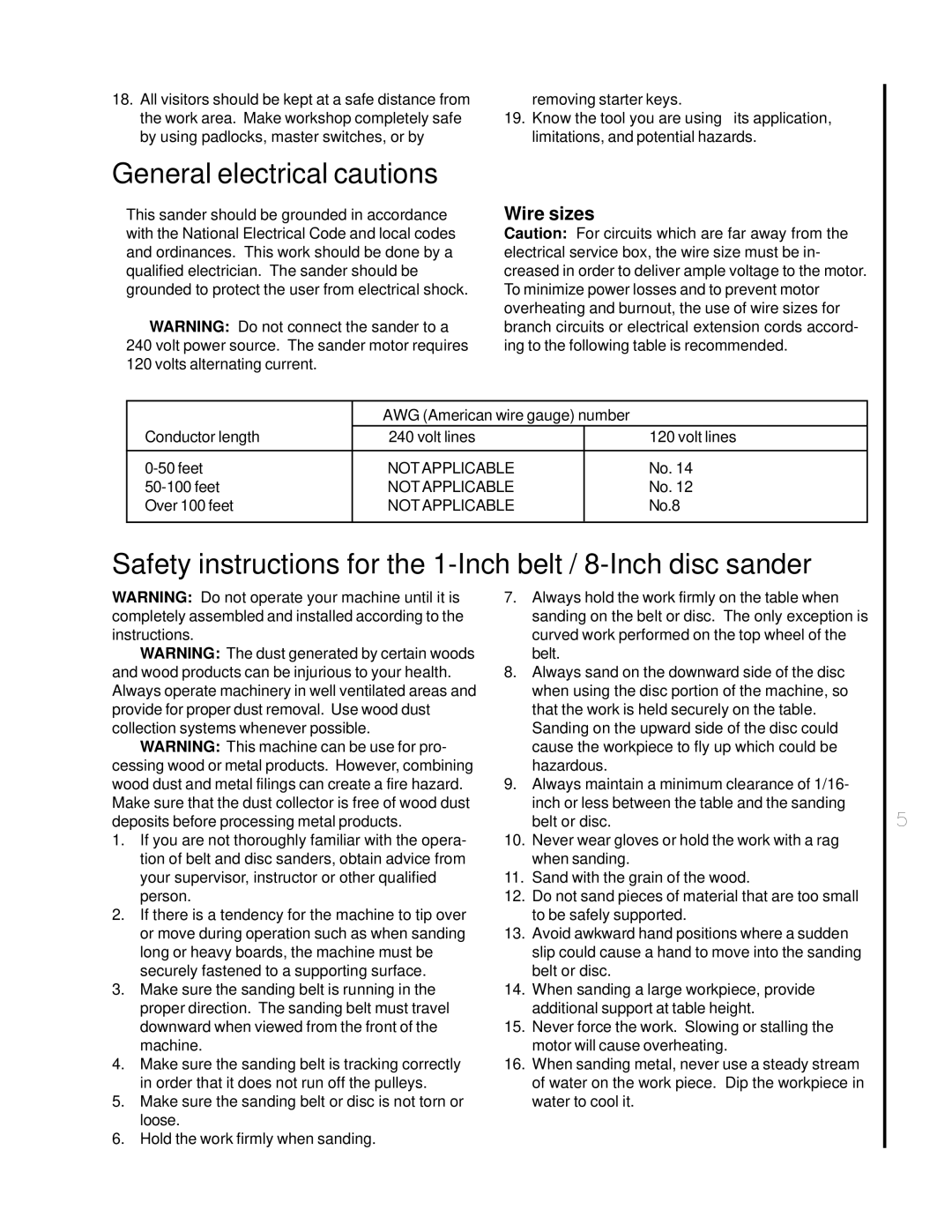

Wire sizes

Caution: For circuits which are far away from the electrical service box, the wire size must be in- creased in order to deliver ample voltage to the motor. To minimize power losses and to prevent motor overheating and burnout, the use of wire sizes for branch circuits or electrical extension cords accord- ing to the following table is recommended.

| AWG (American wire gauge) number |

| |

Conductor length | 240 volt lines |

| 120 volt lines |

|

|

|

|

NOT APPLICABLE |

| No. 14 | |

NOT APPLICABLE |

| No. 12 | |

Over 100 feet | NOT APPLICABLE |

| No.8 |

|

|

|

|

Safety instructions for the

WARNING: Do not operate your machine until it is completely assembled and installed according to the instructions.

WARNING: The dust generated by certain woods and wood products can be injurious to your health. Always operate machinery in well ventilated areas and provide for proper dust removal. Use wood dust collection systems whenever possible.

WARNING: This machine can be use for pro-

cessing wood or metal products. However, combining wood dust and metal filings can create a fire hazard. Make sure that the dust collector is free of wood dust deposits before processing metal products.

1.If you are not thoroughly familiar with the opera- tion of belt and disc sanders, obtain advice from your supervisor, instructor or other qualified person.

2.If there is a tendency for the machine to tip over or move during operation such as when sanding long or heavy boards, the machine must be securely fastened to a supporting surface.

3.Make sure the sanding belt is running in the proper direction. The sanding belt must travel downward when viewed from the front of the machine.

4.Make sure the sanding belt is tracking correctly in order that it does not run off the pulleys.

5.Make sure the sanding belt or disc is not torn or loose.

6.Hold the work firmly when sanding.

7.Always hold the work firmly on the table when sanding on the belt or disc. The only exception is curved work performed on the top wheel of the belt.

8.Always sand on the downward side of the disc when using the disc portion of the machine, so that the work is held securely on the table.

Sanding on the upward side of the disc could cause the workpiece to fly up which could be hazardous.

9.Always maintain a minimum clearance of 1/16- inch or less between the table and the sanding belt or disc.

10.Never wear gloves or hold the work with a rag when sanding.

11.Sand with the grain of the wood.

12.Do not sand pieces of material that are too small to be safely supported.

13.Avoid awkward hand positions where a sudden slip could cause a hand to move into the sanding belt or disc.

14.When sanding a large workpiece, provide additional support at table height.

15.Never force the work. Slowing or stalling the motor will cause overheating.

16.When sanding metal, never use a steady stream of water on the work piece. Dip the workpiece in water to cool it.

5