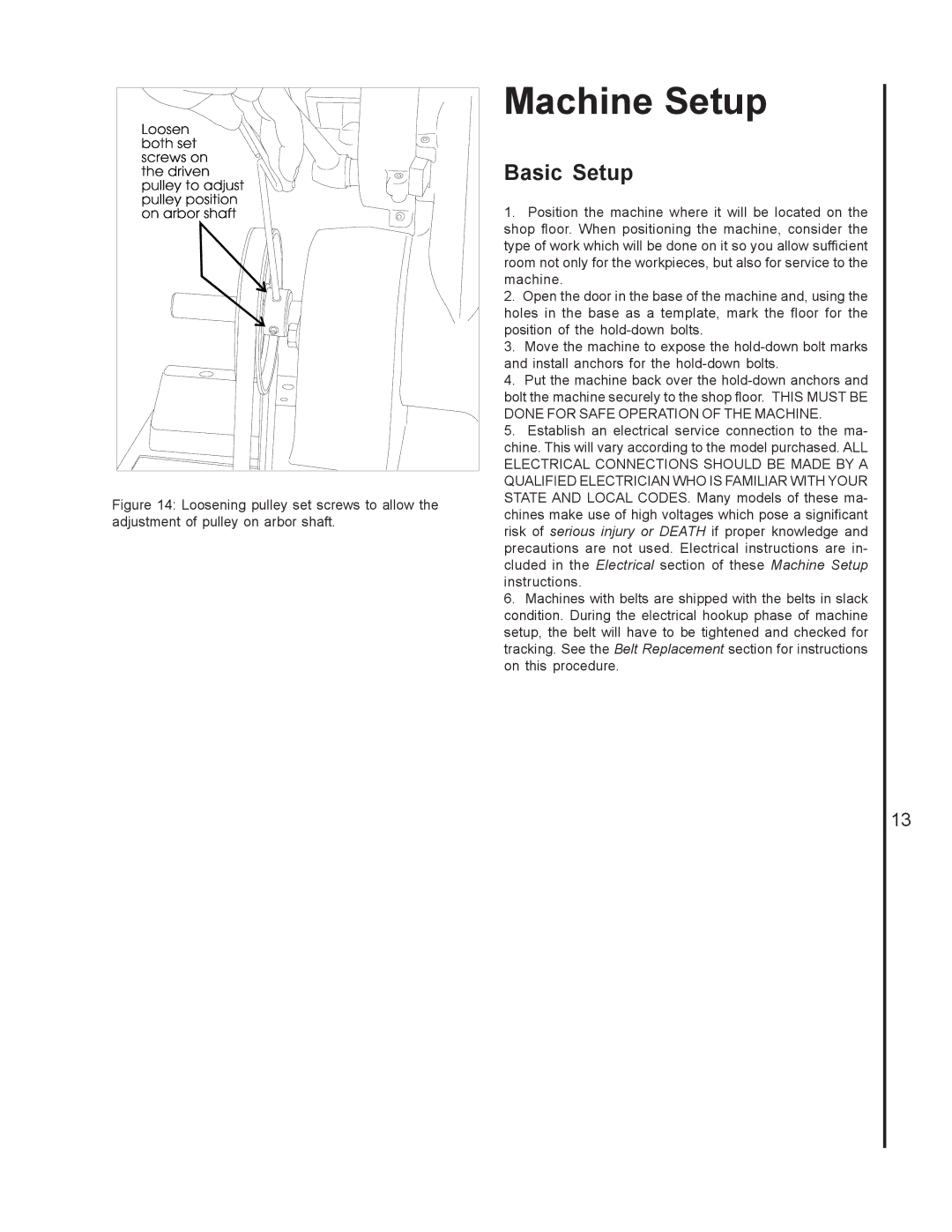

Figure 14: Loosening pulley set screws to allow the adjustment of pulley on arbor shaft.

Machine Setup

Basic Setup

1.Position the machine where it will be located on the shop floor. When positioning the machine, consider the type of work which will be done on it so you allow sufficient room not only for the workpieces, but also for service to the machine.

2.Open the door in the base of the machine and, using the holes in the base as a template, mark the floor for the position of the

3.Move the machine to expose the

4.Put the machine back over the

5.Establish an electrical service connection to the ma- chine. This will vary according to the model purchased. ALL ELECTRICAL CONNECTIONS SHOULD BE MADE BY A QUALIFIED ELECTRICIAN WHO IS FAMILIAR WITH YOUR STATE AND LOCAL CODES. Many models of these ma- chines make use of high voltages which pose a significant risk of serious injury or DEATH if proper knowledge and precautions are not used. Electrical instructions are in- cluded in the Electrical section of these Machine Setup instructions.

6.Machines with belts are shipped with the belts in slack condition. During the electrical hookup phase of machine setup, the belt will have to be tightened and checked for tracking. See the Belt Replacement section for instructions on this procedure.

13