18

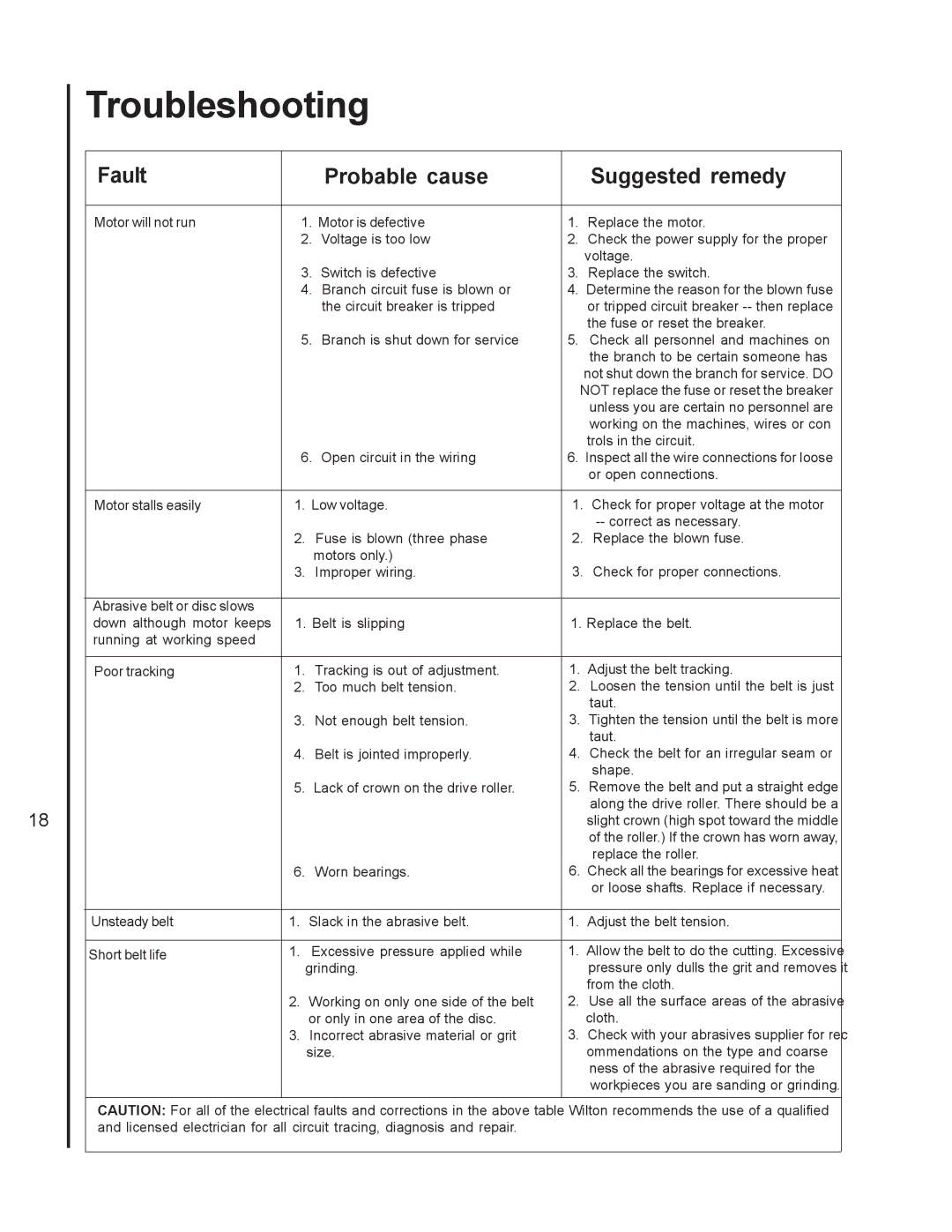

Troubleshooting

Fault |

|

| Probable cause |

| Suggested remedy |

| |

|

|

|

|

| |||

Motor will not run | 1. Motor is defective | 1. | Replace the motor. | ||||

| 2. | Voltage is too low | 2. | Check the power supply for the proper | |||

| 3. | Switch is defective |

| voltage. | |||

| 3. | Replace the switch. | |||||

| 4. | Branch circuit fuse is blown or | 4. Determine the reason for the blown fuse | ||||

|

|

| the circuit breaker is tripped |

| or tripped circuit breaker | ||

| 5. | Branch is shut down for service |

| the fuse or reset the breaker. | |||

| 5. | Check all personnel and machines on | |||||

|

|

|

|

| the branch to be certain someone has | ||

|

|

|

|

| not shut down the branch for service. DO | ||

|

|

|

| NOT replace the fuse or reset the breaker | |||

|

|

|

|

| unless you are certain no personnel are | ||

|

|

|

|

| working on the machines, wires or con | ||

| 6. | Open circuit in the wiring |

| trols in the circuit. | |||

| 6. Inspect all the wire connections for loose | ||||||

|

|

|

|

| or open connections. | ||

|

|

|

|

| |||

Motor stalls easily | 1. Low voltage. | 1. | Check for proper voltage at the motor | ||||

|

|

|

|

| |||

| 2. |

| Fuse is blown (three phase | 2. | Replace the blown fuse. | ||

|

|

| motors only.) | 3. | Check for proper connections. | ||

| 3. |

| Improper wiring. | ||||

|

|

|

|

|

|

|

|

Abrasive belt or disc slows |

|

|

|

|

|

|

|

down although motor keeps | 1. Belt is slipping | 1. Replace the belt. | |||||

running at working speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Poor tracking | 1. |

| Tracking is out of adjustment. | 1. | Adjust the belt tracking. | ||

| 2. |

| Too much belt tension. | 2. | Loosen the tension until the belt is just | ||

|

|

|

|

| taut. | ||

| 3. |

| Not enough belt tension. | 3. | Tighten the tension until the belt is more | ||

|

|

|

|

| taut. | ||

| 4. |

| Belt is jointed improperly. | 4. | Check the belt for an irregular seam or | ||

|

|

|

|

| shape. | ||

| 5. |

| Lack of crown on the drive roller. | 5. | Remove the belt and put a straight edge | ||

|

|

|

|

| along the drive roller. There should be a | ||

|

|

|

|

| slight crown (high spot toward the middle | ||

|

|

|

|

| of the roller.) If the crown has worn away, | ||

|

|

|

|

| replace the roller. | ||

| 6. |

| Worn bearings. | 6. Check all the bearings for excessive heat | |||

|

|

|

|

| or loose shafts. Replace if necessary. | ||

|

|

|

|

|

| ||

Unsteady belt | 1. | Slack in the abrasive belt. | 1. | Adjust the belt tension. | |||

|

|

|

|

|

|

| |

Short belt life | 1. | Excessive pressure applied while | 1. | Allow the belt to do the cutting. Excessive | |||

| grinding. |

| pressure only dulls the grit and removes it | ||||

|

|

|

|

| from the cloth. | ||

| 2. | Working on only one side of the belt | 2. | Use all the surface areas of the abrasive | |||

|

| or only in one area of the disc. |

| cloth. | |||

| 3. | Incorrect abrasive material or grit | 3. | Check with your abrasives supplier for rec | |||

|

| size. |

| ommendations on the type and coarse | |||

|

|

|

|

| ness of the abrasive required for the | ||

|

|

|

|

| workpieces you are sanding or grinding. |

| |

CAUTION: For all of the electrical faults and corrections in the above table Wilton recommends the use of a qualified and licensed electrician for all circuit tracing, diagnosis and repair.