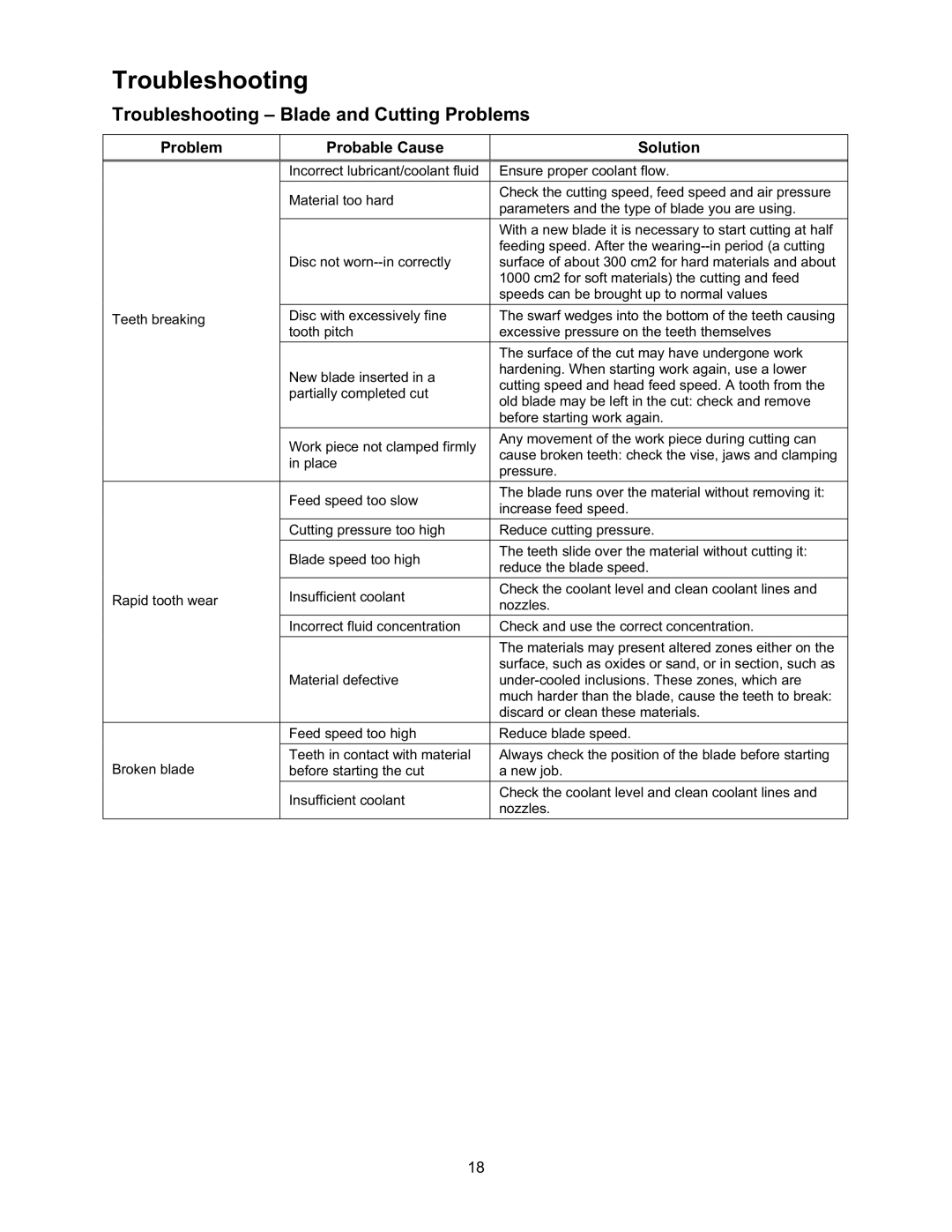

Troubleshooting

Troubleshooting – Blade and Cutting Problems

Problem | Probable Cause | Solution | |

|

|

| |

| Incorrect lubricant/coolant fluid | Ensure proper coolant flow. | |

|

|

| |

| Material too hard | Check the cutting speed, feed speed and air pressure | |

| parameters and the type of blade you are using. | ||

|

| ||

|

|

| |

|

| With a new blade it is necessary to start cutting at half | |

|

| feeding speed. After the | |

| Disc not | surface of about 300 cm2 for hard materials and about | |

|

| 1000 cm2 for soft materials) the cutting and feed | |

|

| speeds can be brought up to normal values | |

|

|

| |

Teeth breaking | Disc with excessively fine | The swarf wedges into the bottom of the teeth causing | |

tooth pitch | excessive pressure on the teeth themselves | ||

| |||

|

|

| |

|

| The surface of the cut may have undergone work | |

| New blade inserted in a | hardening. When starting work again, use a lower | |

| cutting speed and head feed speed. A tooth from the | ||

| partially completed cut | ||

| old blade may be left in the cut: check and remove | ||

|

| ||

|

| before starting work again. | |

|

|

| |

| Work piece not clamped firmly | Any movement of the work piece during cutting can | |

| cause broken teeth: check the vise, jaws and clamping | ||

| in place | ||

| pressure. | ||

|

| ||

|

|

| |

| Feed speed too slow | The blade runs over the material without removing it: | |

| increase feed speed. | ||

|

| ||

|

|

| |

| Cutting pressure too high | Reduce cutting pressure. | |

|

|

| |

| Blade speed too high | The teeth slide over the material without cutting it: | |

| reduce the blade speed. | ||

|

| ||

|

|

| |

Rapid tooth wear | Insufficient coolant | Check the coolant level and clean coolant lines and | |

nozzles. | |||

| |||

|

| ||

|

|

| |

| Incorrect fluid concentration | Check and use the correct concentration. | |

|

|

| |

|

| The materials may present altered zones either on the | |

|

| surface, such as oxides or sand, or in section, such as | |

| Material defective | ||

|

| much harder than the blade, cause the teeth to break: | |

|

| discard or clean these materials. | |

|

|

| |

| Feed speed too high | Reduce blade speed. | |

|

|

| |

| Teeth in contact with material | Always check the position of the blade before starting | |

Broken blade | before starting the cut | a new job. | |

|

|

| |

| Insufficient coolant | Check the coolant level and clean coolant lines and | |

| nozzles. | ||

|

| ||

|

|

|

18