Lower Blade Guide Adjustment

![]() Disconnect machine from the power source, unplug before making any adjustments! Blade teeth are sharp! Use care when working near the saw blade. Failure to comply may cause serious injury!

Disconnect machine from the power source, unplug before making any adjustments! Blade teeth are sharp! Use care when working near the saw blade. Failure to comply may cause serious injury!

1.Blade tension and tracking must be properly adjusted prior to blade guide setup.

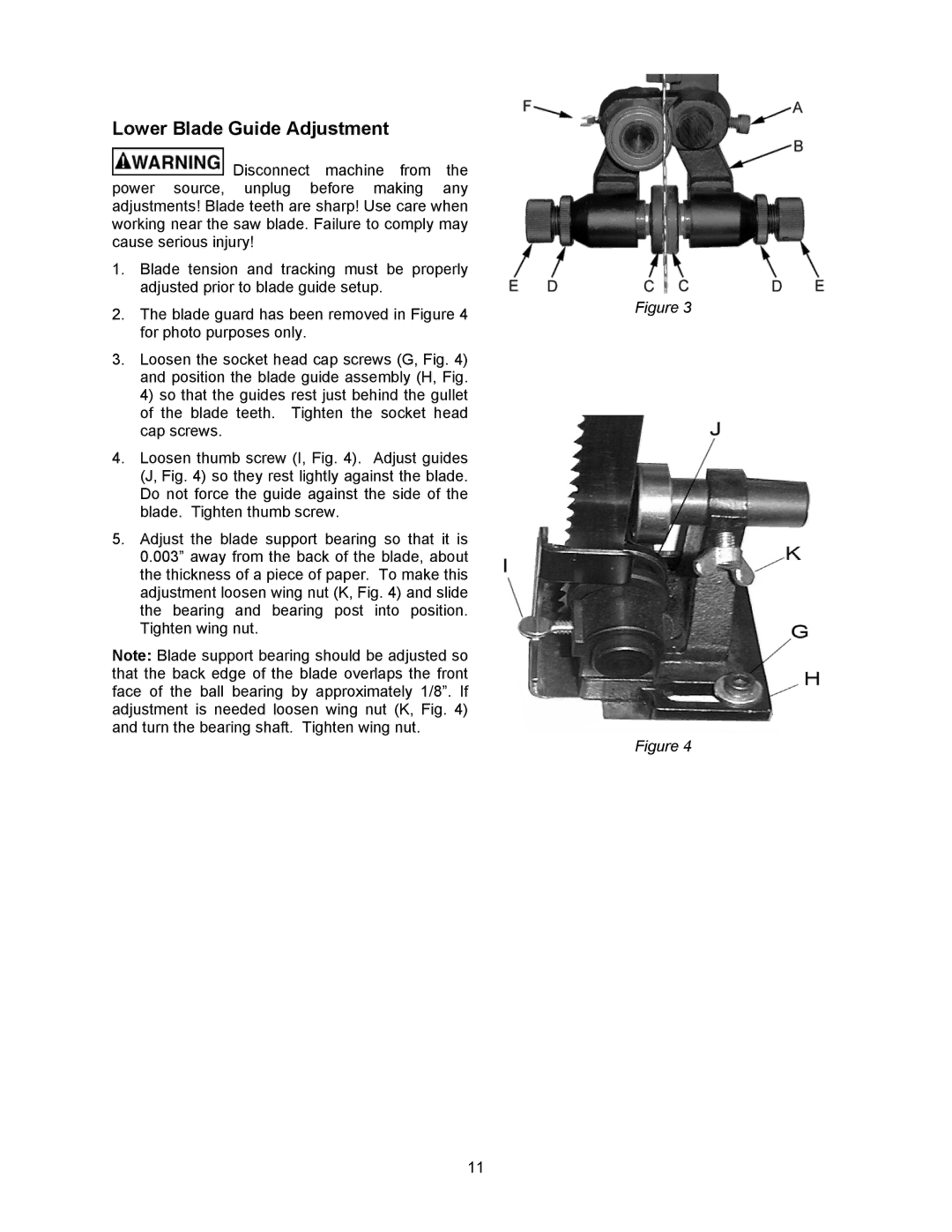

2.The blade guard has been removed in Figure 4 for photo purposes only.

3.Loosen the socket head cap screws (G, Fig. 4) and position the blade guide assembly (H, Fig. 4) so that the guides rest just behind the gullet of the blade teeth. Tighten the socket head cap screws.

4.Loosen thumb screw (I, Fig. 4). Adjust guides (J, Fig. 4) so they rest lightly against the blade. Do not force the guide against the side of the blade. Tighten thumb screw.

5.Adjust the blade support bearing so that it is 0.003” away from the back of the blade, about the thickness of a piece of paper. To make this adjustment loosen wing nut (K, Fig. 4) and slide the bearing and bearing post into position. Tighten wing nut.

Note: Blade support bearing should be adjusted so that the back edge of the blade overlaps the front face of the ball bearing by approximately 1/8”. If adjustment is needed loosen wing nut (K, Fig. 4) and turn the bearing shaft. Tighten wing nut.

11

Figure 3

Figure 4