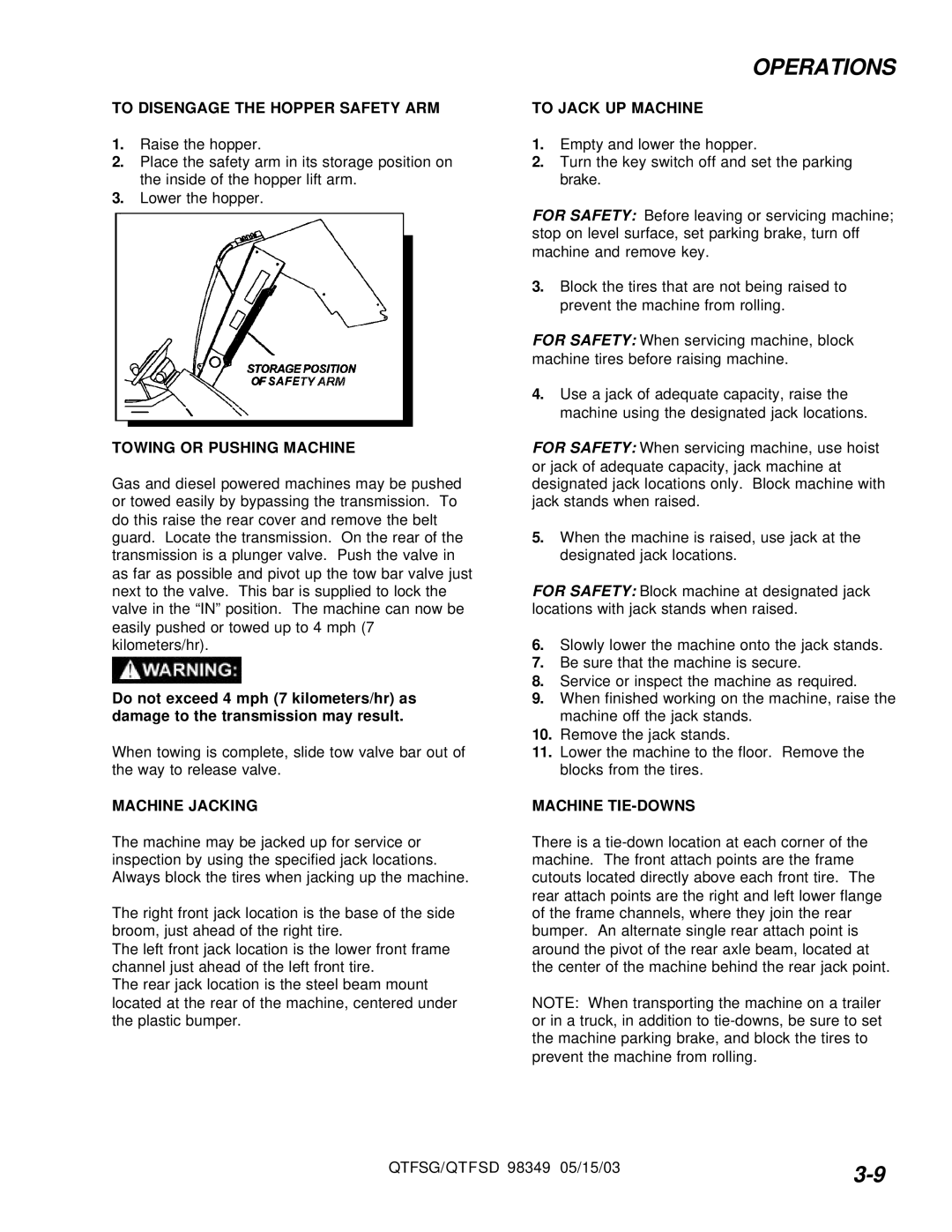

TO DISENGAGE THE HOPPER SAFETY ARM

1.Raise the hopper.

2.Place the safety arm in its storage position on the inside of the hopper lift arm.

3.Lower the hopper.

TOWING OR PUSHING MACHINE

Gas and diesel powered machines may be pushed or towed easily by bypassing the transmission. To do this raise the rear cover and remove the belt guard. Locate the transmission. On the rear of the transmission is a plunger valve. Push the valve in as far as possible and pivot up the tow bar valve just next to the valve. This bar is supplied to lock the valve in the “IN” position. The machine can now be easily pushed or towed up to 4 mph (7 kilometers/hr).

Do not exceed 4 mph (7 kilometers/hr) as damage to the transmission may result.

When towing is complete, slide tow valve bar out of the way to release valve.

MACHINE JACKING

The machine may be jacked up for service or inspection by using the specified jack locations. Always block the tires when jacking up the machine.

The right front jack location is the base of the side broom, just ahead of the right tire.

The left front jack location is the lower front frame channel just ahead of the left front tire.

The rear jack location is the steel beam mount located at the rear of the machine, centered under the plastic bumper.

OPERATIONS

TO JACK UP MACHINE

1.Empty and lower the hopper.

2.Turn the key switch off and set the parking brake.

FOR SAFETY: Before leaving or servicing machine; stop on level surface, set parking brake, turn off machine and remove key.

3.Block the tires that are not being raised to prevent the machine from rolling.

FOR SAFETY: When servicing machine, block machine tires before raising machine.

4.Use a jack of adequate capacity, raise the machine using the designated jack locations.

FOR SAFETY: When servicing machine, use hoist or jack of adequate capacity, jack machine at designated jack locations only. Block machine with jack stands when raised.

5.When the machine is raised, use jack at the designated jack locations.

FOR SAFETY: Block machine at designated jack locations with jack stands when raised.

6.Slowly lower the machine onto the jack stands.

7.Be sure that the machine is secure.

8.Service or inspect the machine as required.

9.When finished working on the machine, raise the machine off the jack stands.

10.Remove the jack stands.

11.Lower the machine to the floor. Remove the blocks from the tires.

MACHINE TIE-DOWNS

There is a

NOTE: When transporting the machine on a trailer or in a truck, in addition to

QTFSG/QTFSD 98349 05/15/03 | |

|