MAINTENANCE

DRIVE WHEEL CHAIN (Refer to the Front Wheel Group in the Parts section)

The drive wheel chain transfers power from the differential shaft to the drive wheels. Check the chain condition and tension every 200 hours of operation.

REPLACING AND ADJUSTING THE DRIVE WHEEL CHAINS

1.Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine, stop on level surface, apply parking brake, turn off machine and remove key.

2.Raise rear cover.

3.Disconnect batteries from machine.

4.Chock the rear wheels. Jack up and remove the front tire.

5.Remove the chain guard and tensioner disk.

6.Check the drive wheel chain for excessive wear. Replace if necessary.

7.Check the drive wheel and differential shaft sprockets to proper alignment. If they are not lined up, loosen the setscrews on the differential shaft sprocket, align the sprockets, and tighten the setscrews.

8.Replace the chain guard and tensioner disk.

9.Check the chain tension. There should be 1/2 inch (1 5 mm) slack measured midway between the sprockets. To adjust the tension, loosen the chain guard mounting bolt and rotate the disk. Tighten the chain guard mounting bolt.

10.Replace the tire and slowly lower the machine to the floor.

11.Repeat the procedure for the other drive tire.

SKIRTS AND SEALS (Refer to the Frame Group and the Main Broom Group in the Parts section)

The main broom skirts prevent dust from exiting the

main broom chamber. The skirts should be inspected for wear or damage daily. When correctly adjusted, they should clear the floor by 0 to 1/8 inch (0 to 3mm).

NOTE: Original equipment skirts are provided with

“Perform Alert™” wear indicators. The wear indicator is raised horizontal line near the lower edge of the skirts. When a skirt is worn to this line it should be replaced. A skirt can be adjusted many times before it wears to the “Perform Alert™” strip. During daily inspections the “Perform Alert™” indicators are useful in determining when skirts are close to requiring replacement.

REPLACING THE RIGHT BROOM DOOR SKIRT

1.Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine, stop on level surface, apply parking brake, turn off machine and remove key.

2.Open the right broom door.

3.Loosen the lower three retaining bolts on the side skirt mounting plate.

4.Slide the worn side skirt out of the skirt retainer.

5.Slide a new skirt into place. Tighten the three retaining bolts.

6.Adjust the side skirt.

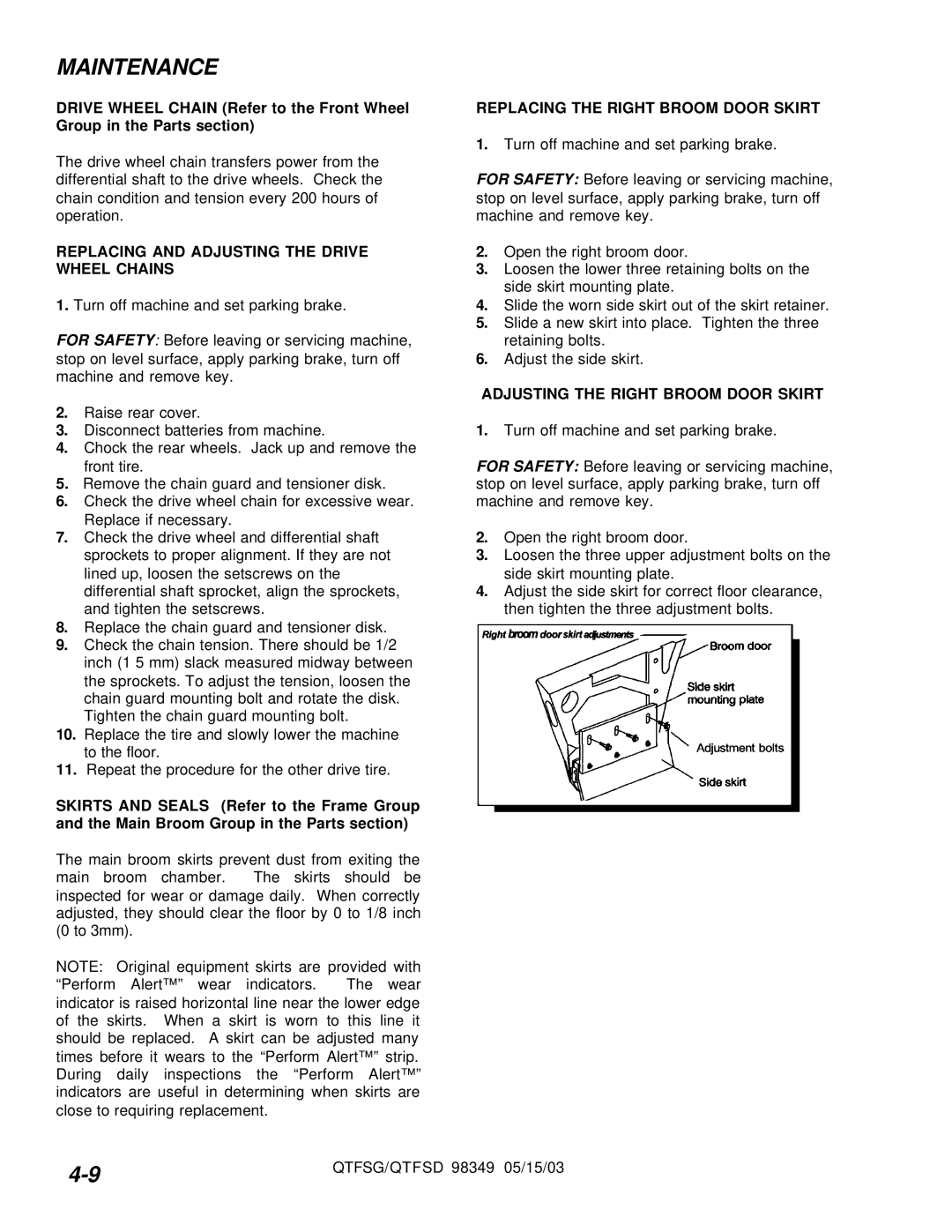

ADJUSTING THE RIGHT BROOM DOOR SKIRT

1.Turn off machine and set parking brake.

FOR SAFETY: Before leaving or servicing machine, stop on level surface, apply parking brake, turn off machine and remove key.

2.Open the right broom door.

3.Loosen the three upper adjustment bolts on the side skirt mounting plate.

4.Adjust the side skirt for correct floor clearance, then tighten the three adjustment bolts.

QTFSG/QTFSD 98349 05/15/03 | |

|