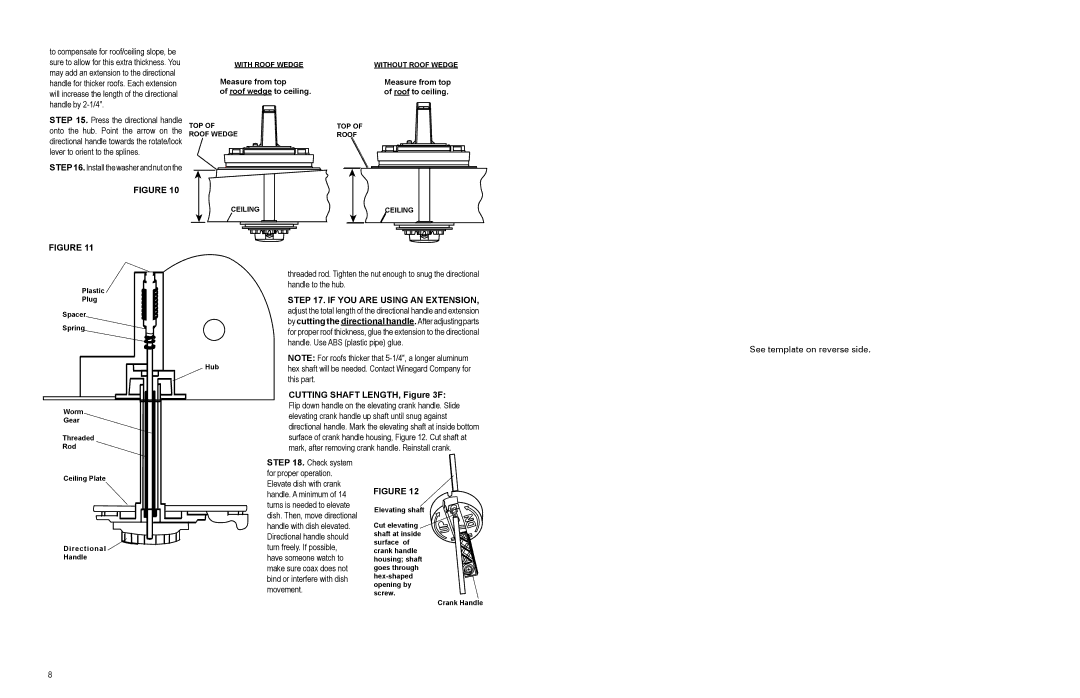

to compensate for roof/ceiling slope, be sure to allow for this extra thickness. You may add an extension to the directional handle for thicker roofs. Each extension will increase the length of the directional handle by

STEP 15. Press the directional handle onto the hub. Point the arrow on the directional handle towards the rotate/lock lever to orient to the splines.

STEP16.Install the washer and nut on the

FIGURE 10

FIGURE 11

WITH ROOF WEDGE

Measure from top

of roof wedge to ceiling.

TOP OF

ROOF WEDGE

➤

CEILING ➤ ![]()

![]()

WITHOUT ROOF WEDGE

Measure from top of roof to ceiling.

TOP OF

ROOF

➤

CEILING

➤

Plastic

Plug

Spacer

Spring

Worm

Gear

Threaded Rod

threaded rod. Tighten the nut enough to snug the directional handle to the hub.

STEP 17. IF YOU ARE USING AN EXTENSION, adjust the total length of the directional handle and extension by cutting the directional handle. After adjusting parts for proper roof thickness, glue the extension to the directional handle. Use ABS (plastic pipe) glue.

NOTE: For roofs thicker that

Hubhex shaft will be needed. Contact Winegard Company for this part.

CUTTING SHAFT LENGTH, Figure 3F: Flip down handle on the elevating crank handle. Slide elevating crank handle up shaft until snug against directional handle. Mark the elevating shaft at inside bottom surface of crank handle housing, Figure 12. Cut shaft at mark, after removing crank handle. Reinstall crank.

See template on reverse side.

Ceiling Plate

Directional ![]() Handle

Handle

STEP 18. Check system for proper operation. Elevate dish with crank handle. A minimum of 14 turns is needed to elevate dish. Then, move directional handle with dish elevated. Directional handle should turn freely. If possible, have someone watch to make sure coax does not bind or interfere with dish movement.

FIGURE 12

Elevating shaft

Cut elevating ![]()

![]() shaft at inside

shaft at inside ![]()

![]() surface of

surface of![]()

![]() crank handle

crank handle![]() housing; shaft

housing; shaft![]() goes through

goes through![]()

![]() opening by

opening by

screw.

Crank Handle

8