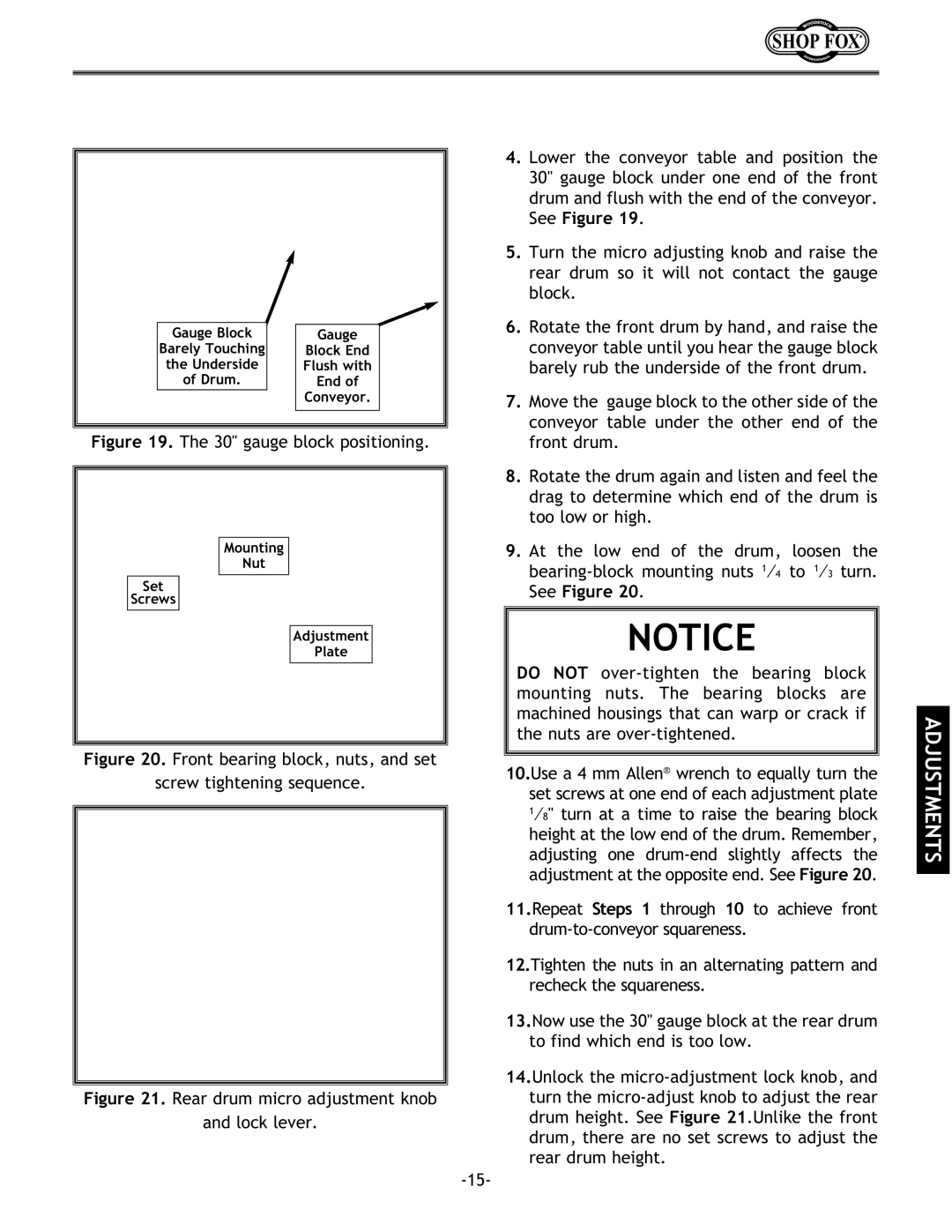

Gauge Block | Gauge |

Barely Touching | Block End |

the Underside | Flush with |

of Drum. | End of |

| Conveyor. |

Figure 19. The 30" gauge block positioning.

Mounting

Nut

Set

Screws

Adjustment

Plate

Figure 20. Front bearing block, nuts, and set

screw tightening sequence.

Figure 21. Rear drum micro adjustment knob

and lock lever.

4.Lower the conveyor table and position the 30" gauge block under one end of the front drum and flush with the end of the conveyor. See Figure 19.

5.Turn the micro adjusting knob and raise the rear drum so it will not contact the gauge block.

6.Rotate the front drum by hand, and raise the conveyor table until you hear the gauge block barely rub the underside of the front drum.

7.Move the gauge block to the other side of the conveyor table under the other end of the front drum.

8.Rotate the drum again and listen and feel the drag to determine which end of the drum is too low or high.

9.At the low end of the drum, loosen the

NOTICE

DO NOT

10.Use a 4 mm Allen® wrench to equally turn the set screws at one end of each adjustment plate

1⁄8" turn at a time to raise the bearing block height at the low end of the drum. Remember, adjusting one

11.Repeat Steps 1 through 10 to achieve front

12.Tighten the nuts in an alternating pattern and recheck the squareness.

13.Now use the 30" gauge block at the rear drum to find which end is too low.

14.Unlock the

ADJUSTMENTS