ADJUSTMENTS

PART 2: Drum-to-Conveyor Parallelism

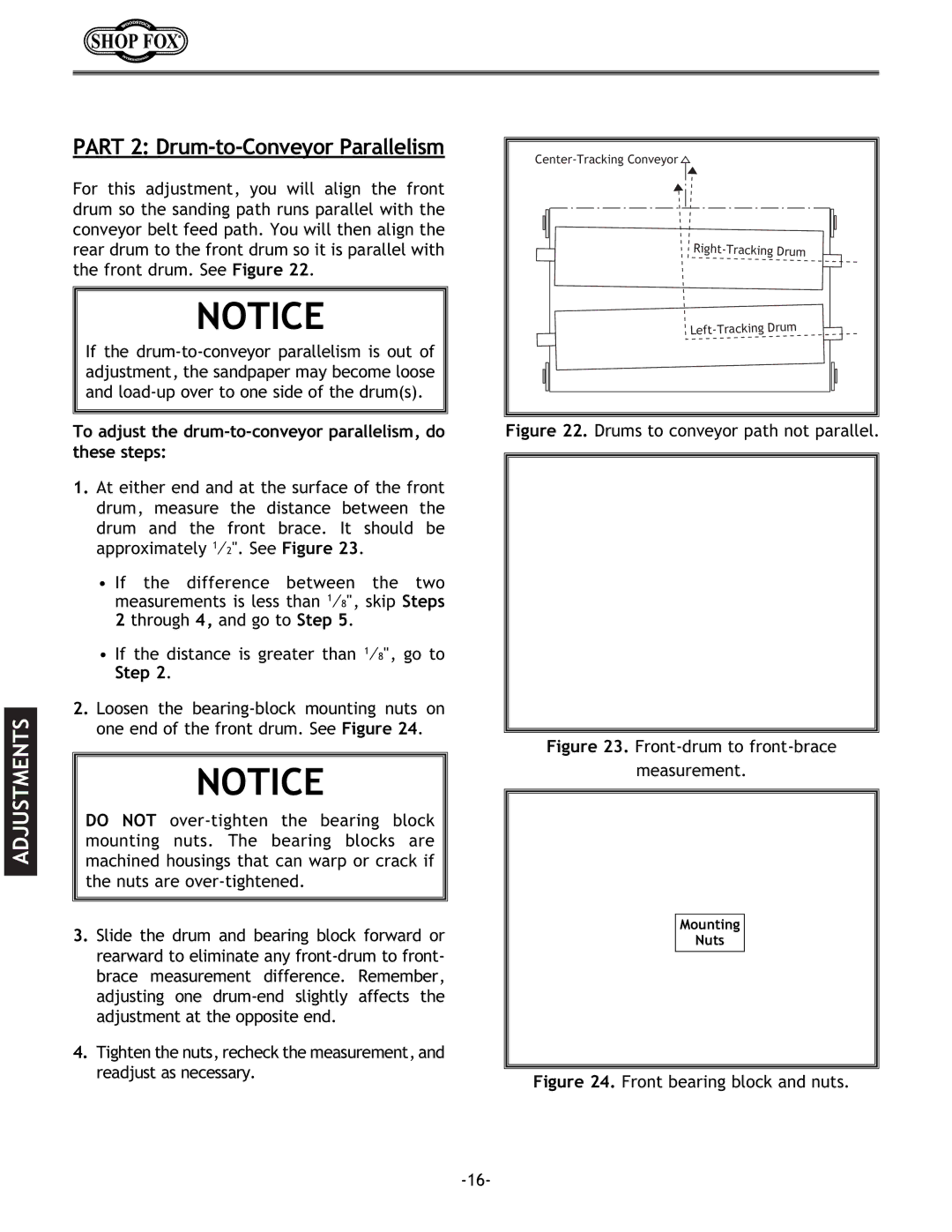

For this adjustment, you will align the front drum so the sanding path runs parallel with the conveyor belt feed path. You will then align the rear drum to the front drum so it is parallel with the front drum. See Figure 22.

NOTICE

If the

To adjust the drum-to-conveyor parallelism, do these steps:

1.At either end and at the surface of the front drum, measure the distance between the drum and the front brace. It should be approximately 1⁄2". See Figure 23.

•If the difference between the two measurements is less than 1⁄8", skip Steps 2 through 4, and go to Step 5.

•If the distance is greater than 1⁄8", go to

Step 2.

2.Loosen the

NOTICE

DO NOT

3.Slide the drum and bearing block forward or rearward to eliminate any

4.Tighten the nuts, recheck the measurement, and readjust as necessary.

Figure 22. Drums to conveyor path not parallel.

1⁄2"

Figure 23. Front-drum to front-brace

measurement.

Mounting

Nuts