Figure 25. The 25⁄8" gauge block positioning.

Mounting

Nuts

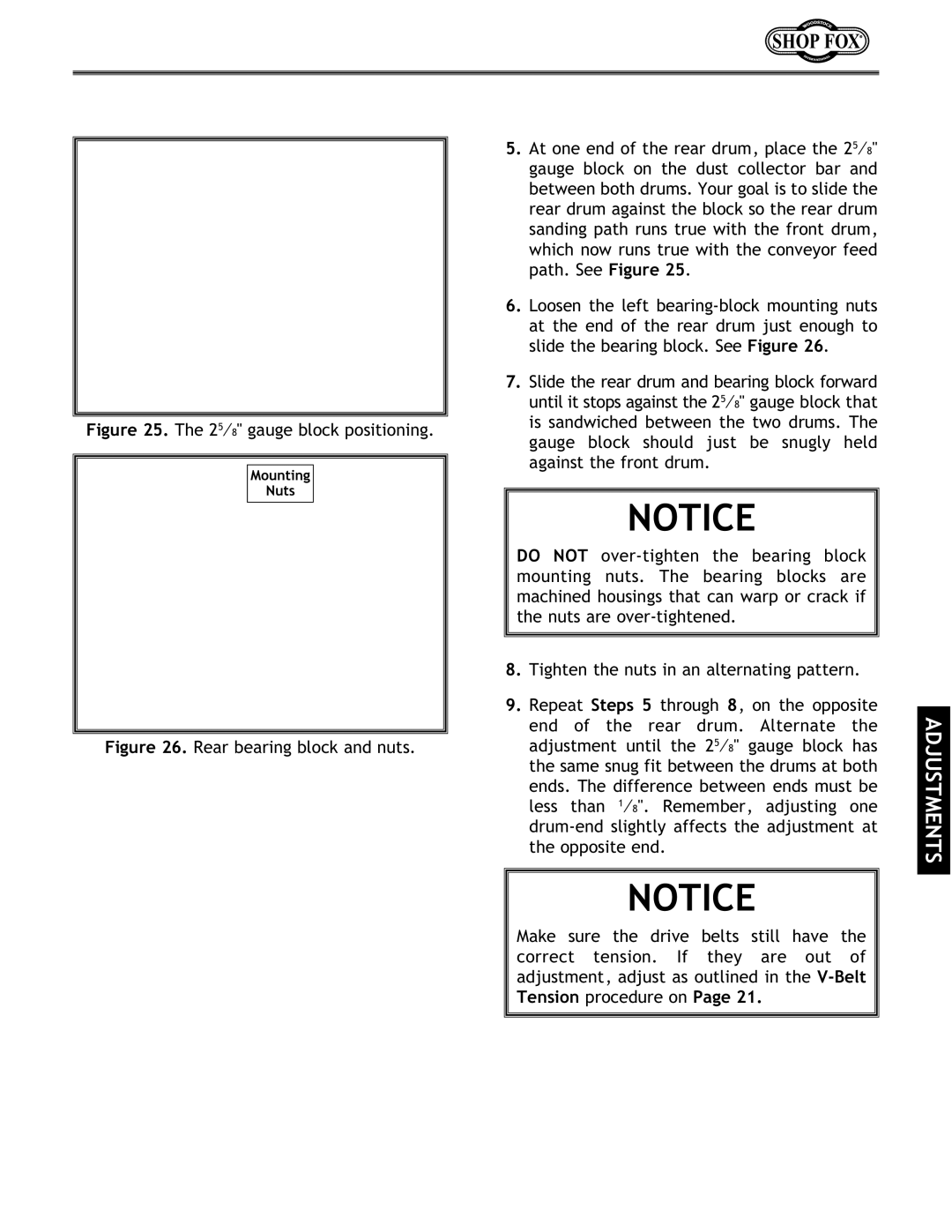

Figure 26. Rear bearing block and nuts.

5.At one end of the rear drum, place the 25⁄8" gauge block on the dust collector bar and between both drums. Your goal is to slide the rear drum against the block so the rear drum sanding path runs true with the front drum, which now runs true with the conveyor feed path. See Figure 25.

6.Loosen the left bearing-block mounting nuts at the end of the rear drum just enough to slide the bearing block. See Figure 26.

7.Slide the rear drum and bearing block forward until it stops against the 25⁄8" gauge block that is sandwiched between the two drums. The gauge block should just be snugly held against the front drum.

NOTICE

DO NOT over-tighten the bearing block mounting nuts. The bearing blocks are machined housings that can warp or crack if the nuts are over-tightened.

8.Tighten the nuts in an alternating pattern.

9.Repeat Steps 5 through 8, on the opposite end of the rear drum. Alternate the adjustment until the 25⁄8" gauge block has the same snug fit between the drums at both ends. The difference between ends must be less than 1⁄8". Remember, adjusting one drum-end slightly affects the adjustment at the opposite end.

NOTICE

Make sure the drive belts still have the correct tension. If they are out of adjustment, adjust as outlined in the

ADJUSTMENTS