Spindle Turning

W1758 Owner's Manual (Mfg. Since 3/10)

OPERATIONS

Spindle Turning

Spindle turning is the operation performed when a workpiece is mounted between the headstock and tailstock centers (see Figure 26).

Before beginning any turning operation, make sure the headstock and tailstock centers are properly aligned. Refer to Aligning Headstock & Tailstock Centers on Page 28 for instructions on this proce- dure. Failure to heed this warning could result in the spinning workpiece being thrown from the lathe resulting in death or serious personal injury.

To set up a spindle turning operation, do these steps:

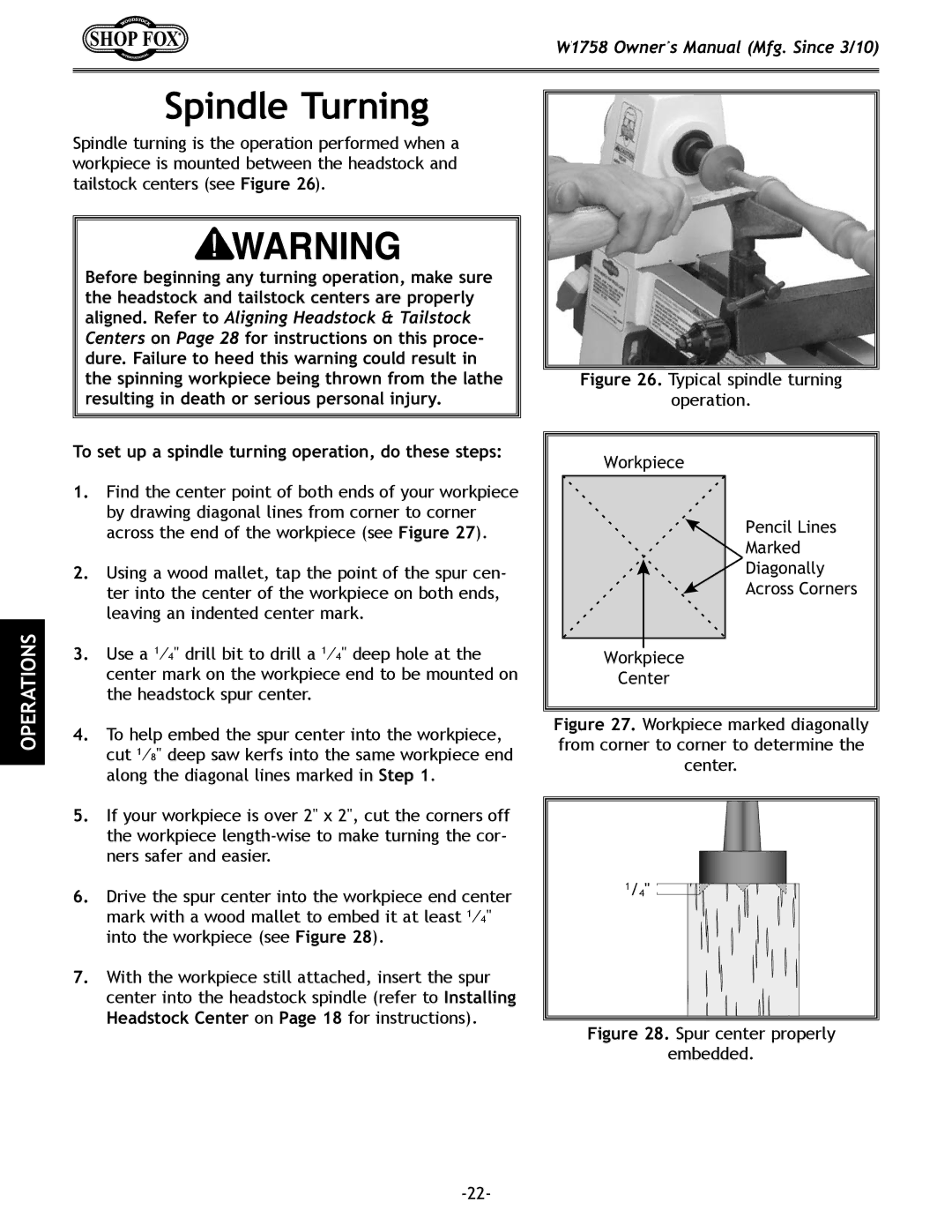

1.Find the center point of both ends of your workpiece by drawing diagonal lines from corner to corner across the end of the workpiece (see Figure 27).

2.Using a wood mallet, tap the point of the spur cen- ter into the center of the workpiece on both ends, leaving an indented center mark.

3.Use a 1⁄4" drill bit to drill a 1⁄4" deep hole at the center mark on the workpiece end to be mounted on the headstock spur center.

Figure 26. Typical spindle turning

operation.

Workpiece

Pencil Lines

Marked

Diagonally

Across Corners

Workpiece

Center

4.To help embed the spur center into the workpiece, cut 1⁄8" deep saw kerfs into the same workpiece end along the diagonal lines marked in Step 1.

5.If your workpiece is over 2" x 2", cut the corners off the workpiece length-wise to make turning the cor- ners safer and easier.

6.Drive the spur center into the workpiece end center mark with a wood mallet to embed it at least 1⁄4" into the workpiece (see Figure 28).

7.With the workpiece still attached, insert the spur center into the headstock spindle (refer to Installing Headstock Center on Page 18 for instructions).

Figure 27. Workpiece marked diagonally from corner to corner to determine the center.

1/4"