Faceplate Turning

W1758 Owner's Manual (Mfg. Since 3/10)

OPERATIONS

Faceplate Turning

Faceplate turning is when a workpiece is mounted to the faceplate that, in turn, is secured to the headstock spin- dle. This type of turning is usually done with

To mount the workpiece onto the faceplate, do these steps:

1.Mark the center of the workpiece back, as in Spindle Turning on Page 22.

Note: Cut off the excess corners of the workpiece to make it as close to "round" as possible.

2.Use the mark made from Step 1 to center the face- plate on the workpiece back, and attach it with wood screws that do not have tapered heads (see

Figures 31 & 32).

3.Thread and secure the faceplate onto the headstock spindle (refer to Installing Faceplate on Page 20 for detailed instructions).

If wood screws cannot be placed in the workpiece, then the faceplate can be mounted to a backing block that is securely glued to the workpiece.

To mount your workpiece to a backing block, do these steps:

1.Make the backing block from a piece of scrap wood that is flat on both sides, and is free of knots and splits.

2.Locate and mark the center of both the workpiece and the backing block.

3.Drill a 1⁄4" hole completely through the backing block at its center.

4.Looking through the hole in the backing block to line it up with the center of the workpiece, glue and clamp the backing block to the workpiece.

Note: Allow the glue joint to completely cure according to the manufacturer's instructions.

Figure 30. Typical faceplate turning

operation.

Figure 31. Typical attachment of faceplate to workpiece (shown with backing block).

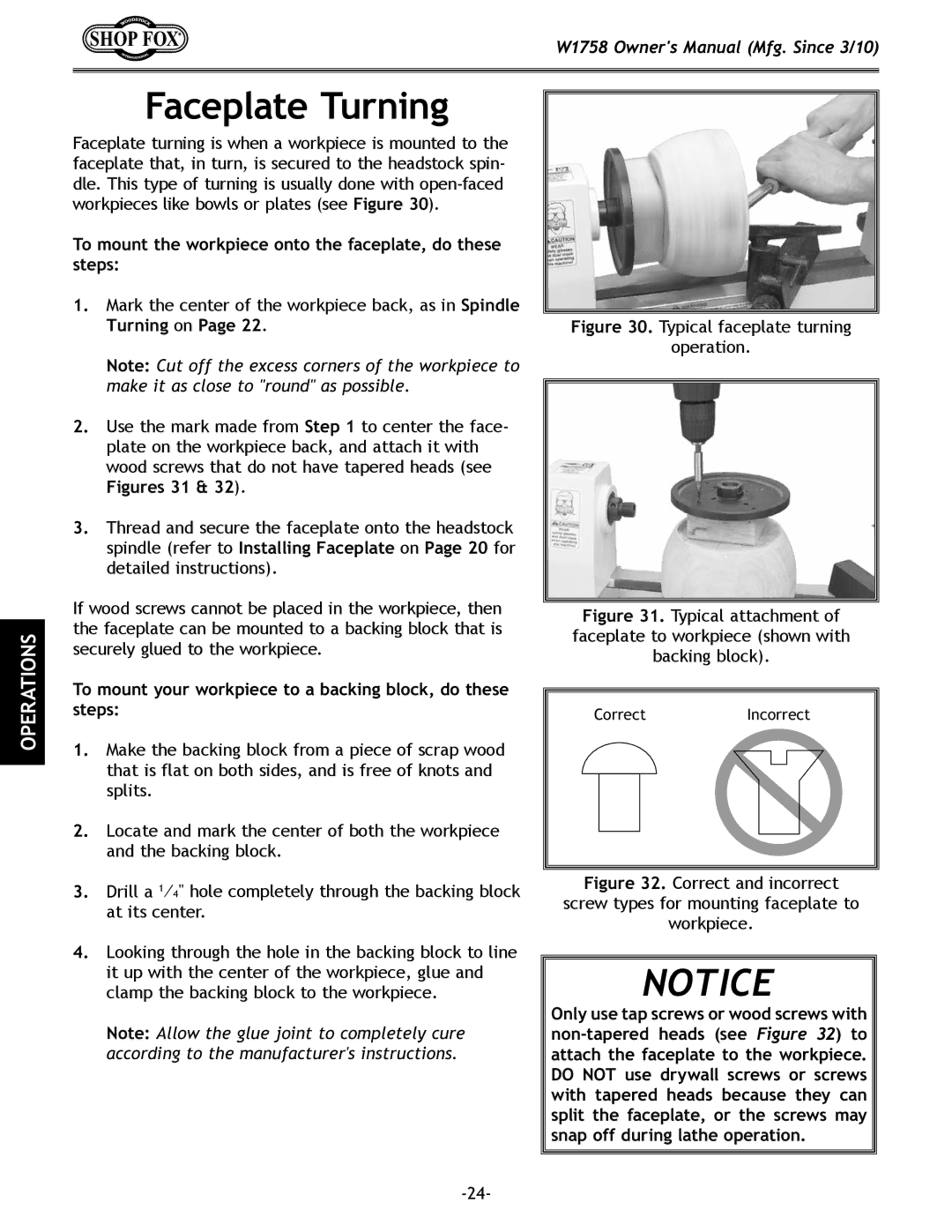

CorrectIncorrect

Figure 32. Correct and incorrect

screw types for mounting faceplate to

workpiece.

NOTICE

Only use tap screws or wood screws with