W1758 Owner's Manual (Mfg. Since 3/10)

Outboard Turning

Outboard turning is a variation of faceplate turning and is usually done when stock diameter is greater than 12". For the size of the Model W1758 and its minimum turn- ing speed, we recommend not exceeding a maximum workpiece diameter of 17".

Figure 33 depicts the lathe setup at 90° and using the provided tool rest extension. Figure 34 shows the head- stock setup for outboard turning at 180°.

It is important for safety and performance to use the pro- vided tool rest extension in a manner that will offer the greatest stability and range for your turning tool. If this tool rest assembly will not work for your operation, you must use a free-standing tool rest (not supplied).

Sanding/Finishing Using

the Lathe

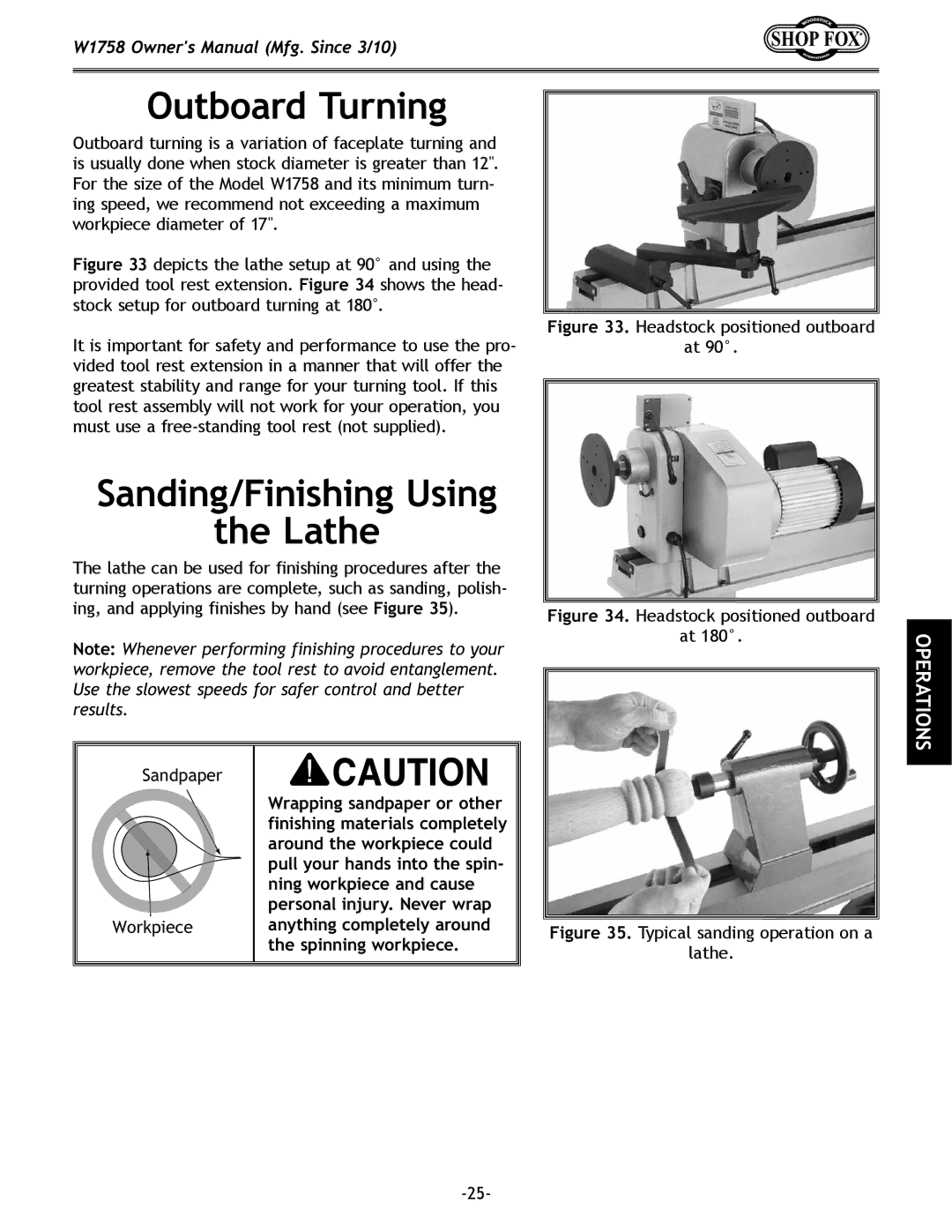

The lathe can be used for finishing procedures after the turning operations are complete, such as sanding, polish- ing, and applying finishes by hand (see Figure 35).

Note: Whenever performing finishing procedures to your workpiece, remove the tool rest to avoid entanglement. Use the slowest speeds for safer control and better results.

Figure 33. Headstock positioned outboard

at 90°.

Figure 34. Headstock positioned outboard

at 180°.

OPERATIONS

Sandpaper

Workpiece

Wrapping sandpaper or other finishing materials completely around the workpiece could pull your hands into the spin- ning workpiece and cause personal injury. Never wrap anything completely around the spinning workpiece.