wooden frame into the internal wall and make good the hole.

2.Offer the fan box 6 up to the wall.

3.Screw the fan box 6 to the wooden frame using the slots in the flange (screws not supplied).

If mounting in a ceiling (flush mounting)

1.The surround 0 is not required.

2.Insert the fan box 6 into the hole and mark four positions using the slots in the flange B.

3.Remove the fan box 6 from ceiling and fit the four ceiling clips (supplied) over the edge of the hole, so that the clips align with the marks on the ceiling B.

4.Drill 4 pilot holes into the ceiling through the hole of each clip, ensuring not to damage the clip.

5.Fit the ducting to the circular spigot 7.

6.Offer the fan box 6 up to the ceiling.

7.Slit the cable grommet. Pass the electrical cable into the fan box 6 through

the front cable inlet hole.

Ensure cable grommet is in place and a tight fit.

8.Using the screws !¡ (Fig.B), fix the fan box flange to the ceiling clips.

Terminating the ducting

Fit an outer grille (such as CFWG100, not supplied in the DX200/DX200T) to the outer wall. For ceiling mounting, use appropriate ancillaries (not supplied).

Wire the electrical connections

WARNING! THIS APPLIANCE MUST BE EARTHED

1.Isolate the electricity supply and remove all fuses. The terminal block will accept cable up to 1.5mm2

2.Use a

3.Use suitably rated

4.Remove the retaining screws of the terminal cover, if still in position.

5.Wire the fan as shown in F using the cable clamp provided. Check fan model to diagram.

DX200: “LH” =Live (High Speed)/ “LL” = Live(Low Speed)

6.Replace the terminal cover 5 and fasten the retaining screws.

7.See section on “User adjustments” if you wish to use settings other than those that have been factory set.

8.Refit the front cover(Fig.C).

Connect the cable from the isolating switch to electrical supply wiring, and

10.Refit fuses before turning on electricity supply.

11.For fixed wiring circuits, the protective fuse for the appliance must not exceed 5A.

For Australia Only

CF20 – Connection to the supply - flexible

ALL OTHERS – Permanently connected to the supply and a remote switch controls operation. They should be directly wired to the supply through an approved 10Awall mounted surface switch with at least 3mm clearance between contacts.

User adjustments

Before making any adjustments, isolate the fan completely from the mains supply, check specification below to see which features apply to your fan.

1.Remove the front cover and replace after adjustment (Fig. C)

DX200

There are no user adjustments for this fan.

DX200T

1.The timer

seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T” (Fig.D), clockwise to increase time,

CF20

1.The humidity setting is adjustable between approximately 50% and 90%

relative humidity. Use an electrician’s screwdriver, and turn screw “RH” (Fig.D), clockwise to increase the relative humidity setting and

CF20T

1.The timer

seconds and 20 minutes. Use an electrician’s screwdriver and turn screw “T” (Fig.D), clockwise to increase time,

2.The humidity setting is adjustable between approximately 50% and 90%

relative humidity. Use an electrician’s screwdriver, and turn screw “RH” (Fig.D), clockwise to increase the relative humidity setting and

Using the fan

DX200

Operate the fan using the external on/off switch. Repeat to switch off.

The fan speed is

DX200T

Operate the fan using the external on/off switch. Repeat to switch off.

When the switch is turned off, the fan continues to operate for the selected over- run timer period. Top Light “I” is lit when the external on/off switch is switched on. The fan speed is

Time delay start feature on or off

This is set by the installer to provide a

CF20 / CF20T

Switched Operation

The fan can be wired with a separate on/off switch. Fan operates at condensation speed when switched on. Top “Light I” is lit when the separate on/off switch is switched on. When switched off, the fan will continue to operate if the humidity level exceeds the set level. CF20T only: When switched off, the fan continues to operate at condensation speed for the adjustable timer

Condensation Operation

The fan operates at condensation control speed, when the relative humidity exceeds the set level, and turns off when the humidity drops.

Boost Operation

The integral pull cord switch switches the fan to run at high speed. Bottom “Light II” is lit when the fan is operating at high speed.

Note: If the separate on/off switch and integral pull cord are both on, then Lights “I” and “II” will both be lit and the fan will run at high speed.

CF20T only

Time delay start feature on or off

This is set by the installer to provide a

Cleaning

Before cleaning, isolate the fan completely from the mains supply

Only clean the external surface of the fan, using a damp lint free cloth. Do not use strong detergents, solvents or chemical cleaners

Allow fan to dry thoroughly before use.

Apart from cleaning, no other maintenance is required.

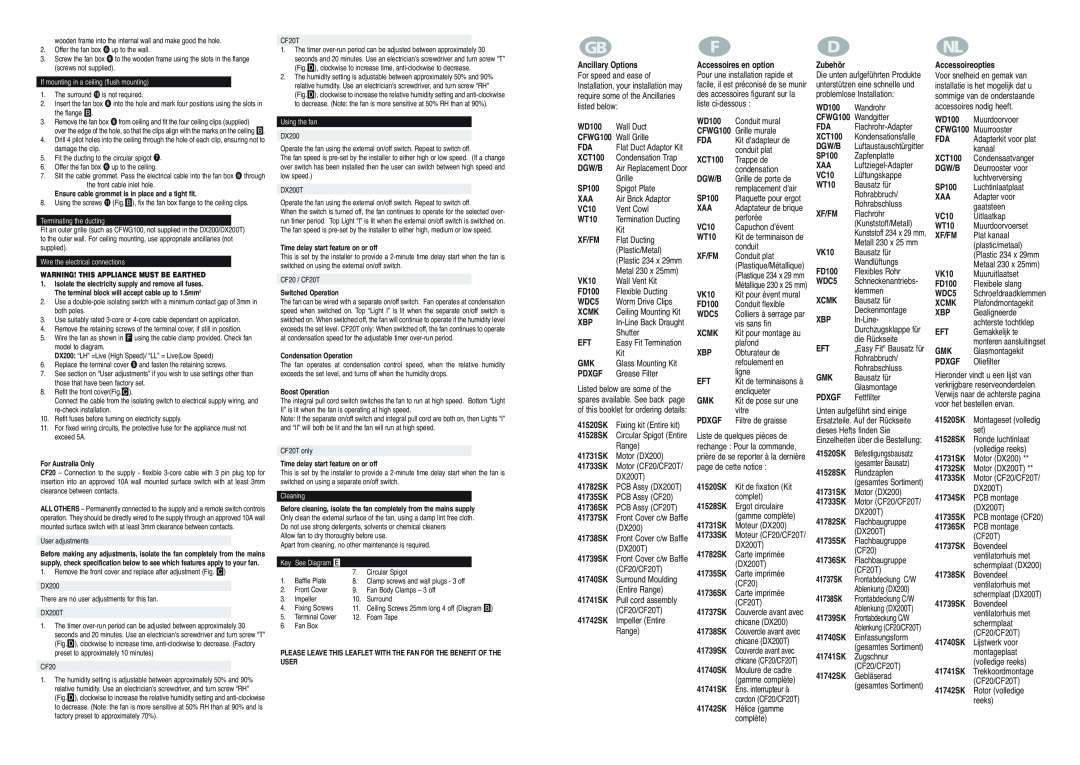

Key See Diagram E

1. | Baffle Plate | 7. | Circular Spigot |

8. | Clamp screws and wall plugs - 3 off | ||

2. | Front Cover | 9. | Fan Body Clamps – 3 off |

3. | Impeller | 10. | Surround |

4. | Fixing Screws | 11. | Ceiling Screws 25mm long 4 off (Diagram B) |

5. | Terminal Cover | 12. | Foam Tape |

6.Fan Box

PLEASE LEAVE THIS LEAFLET WITH THE FAN FOR THE BENEFIT OF THE USER

GB

Ancillary Options

For speed and ease of Installation, your installation may require some of the Ancillaries listed below:

WD100 | Wall Duct |

CFWG100 | Wall Grille |

FDA | Flat Duct Adaptor Kit |

XCT100 | Condensation Trap |

DGW/B | Air Replacement Door |

SP100 | Grille |

Spigot Plate | |

XAA | Air Brick Adaptor |

VC10 | Vent Cowl |

WT10 | Termination Ducting |

XF/FM | Kit |

Flat Ducting | |

| (Plastic/Metal) |

| (Plastic 234 x 29mm |

VK10 | Metal 230 x 25mm) |

Wall Vent Kit | |

FD100 | Flexible Ducting |

WDC5 | Worm Drive Clips |

XCMK | Ceiling Mounting Kit |

XBP | |

EFT | Shutter |

Easy Fit Termination | |

GMK | Kit |

Glass Mounting Kit | |

PDXGF | Grease Filter |

Listed below are some of the spares available. See back page of this booklet for ordering details:

41520SK Fixing kit (Entire kit) 41528SK Circular Spigot (Entire Range)

41731SK Motor (DX200) 41733SK Motor (CF20/CF20T/

DX200T)

41782SK PCB Assy (DX200T) 41735SK PCB Assy (CF20) 41736SK PCB Assy (CF20T) 41737SK Front Cover c/w Baffle (DX200)

41738SK Front Cover c/w Baffle (DX200T)

41739SK Front Cover c/w Baffle (CF20/CF20T)

41740SK Surround Moulding (Entire Range)

41741SK Pull cord assembly (CF20/CF20T)

41742SK Impeller (Entire Range)

F

Accessoires en option

Pour une installation rapide et facile, il est préconisé de se munir des accessoires figurant sur la liste

WD100 Conduit mural CFWG100 Grille murale

FDA Kit d'adapteur de conduit plat

XCT100 Trappe de condensation

DGW/B Grille de porte de remplacement d’air SP100 Plaquette pour ergot

XAA Adaptateur de brique perforée

VC10 Capuchon d’évent WT10 Kit de terminaison de conduit

XF/FM Conduit plat (Plastique/Métallique) (Plastique 234 x 29 mm Métallique 230 x 25 mm)

VK10 Kit pour évent mural FD100 Conduit flexible WDC5 Colliers à serrage par

vis sans fin

XCMK Kit pour montage au plafond

XBP Obturateur de refoulement en ligne

EFT Kit de terminaisons à encliqueter

GMK Kit de pose sur une vitre

PDXGF Filtre de graisse

Liste de quelques pièces de rechange : Pour la commande, prière de se reporter à la dernière page de cette notice :

41520SK Kit de fixation (Kit complet)

41528SK Ergot circulaire (gamme complète)

41731SK Moteur (DX200) 41733SK Moteur (CF20/CF20T/

DX200T)

41782SK Carte imprimée (DX200T)

41735SK Carte imprimée (CF20)

41736SK Carte imprimée (CF20T)

41737SK Couvercle avant avec chicane (DX200)

41738SK Couvercle avant avec chicane (DX200T)

41739SK Couvercle avant avec chicane (CF20/CF20T)

41740SK Moulure de cadre (gamme complète)

41741SK Ens. interrupteur à cordon (CF20/CF20T)

41742SK Hélice (gamme complète)

D

Zubehör

Die unten aufgeführten Produkte unterstützen eine schnelle und problemlose Installation:

WD100 | Wandrohr |

CFWG100 | Wandgitter |

FDA | |

XCT100 | Kondensationsfalle |

DGW/B | Luftaustauschtürgitter |

SP100 | Zapfenplatte |

XAA | |

VC10 | Lüftungskappe |

WT10 | Bausatz für |

| Rohrabbruch/ |

XF/FM | Rohrabschluss |

Flachrohr | |

| (Kunststoff/Metall) |

| Kunststoff 234 x 29 mm, |

VK10 | Metall 230 x 25 mm |

Bausatz für | |

FD100 | Wandlüftungs |

Flexibles Rohr | |

WDC5 | Schneckenantriebs- |

XCMK | klemmen |

Bausatz für | |

XBP | Deckenmontage |

| Durchzugsklappe für |

EFT | die Rückseite |

„Easy Fit" Bausatz für | |

| Rohrabbruch/ |

GMK | Rohrabschluss |

Bausatz für | |

PDXGF | Glasmontage |

Fettfilter |

Unten aufgeführt sind einige Ersatzteile. Auf der Rückseite dieses Hefts finden Sie Einzelheiten über die Bestellung:

41520SK Befestigungsbausatz

(gesamter Bausatz)

41528SK Rundzapfen

(gesamtes Sortiment)

41731SK Motor (DX200)

41733SK Motor (CF20/CF20T/

DX200T)

41782SK Flachbaugruppe

(DX200T)

41735SK Flachbaugruppe

(CF20)

41736SK Flachbaugruppe

(CF20T)

41737SK Frontabdeckung C/W

Ablenkung (DX200)

41738SK Frontabdeckung C/W

Ablenkung (DX200T)

41739SK Frontabdeckung C/W

Ablenkung (CF20/CF20T)

41740SK Einfassungsform

(gesamtes Sortiment)

41741SK Zugschnur

(CF20/CF20T)

41742SK Gebläserad

(gesamtes Sortiment)

NL

Accessoireopties

Voor snelheid en gemak van installatie is het mogelijk dat u sommige van de onderstaande accessoires nodig heeft.

WD100 | Muurdoorvoer |

CFWG100 | Muurrooster |

FDA | Adapterkit voor plat |

XCT100 | kanaal |

Condensaatvanger | |

DGW/B | Deurrooster voor |

SP100 | luchtverversing |

Luchtinlaatplaat | |

XAA | Adapter voor |

VC10 | gaatsteen |

Uitlaatkap | |

WT10 | Muurdoorvoerset |

XF/FM | Plat kanaal |

| (plastic/metaal) |

| (Plastic 234 x 29mm |

VK10 | Metaal 230 x 25mm) |

Muuruitlaatset | |

FD100 | Flexibele slang |

WDC5 | Schroefdraadklemmen |

XCMK | Plafondmontagekit |

XBP | Gealigneerde |

EFT | achterste tochtklep |

Gemakkelijk te | |

GMK | monteren aansluitingset |

Glasmontagekit | |

PDXGF | Oliefilter |

Hieronder vindt u een lijst van verkrijgbare reserveonderdelen. Verwijs naar de achterste pagina voor het bestellen ervan.

41520SK Montageset (volledig set)

41528SK Ronde luchtinlaat (volledige reeks)

41731SK Motor (DX200) ** 41732SK Motor (DX200T) ** 41733SK Motor (CF20/CF20T/ DX200T)

41734SK PCB montage (DX200T)

41735SK PCB montage (CF20) 41736SK PCB montage

(CF20T)

41737SK Bovendeel ventilatorhuis met schermplaat (DX200)

41738SK Bovendeel ventilatorhuis met schermplaat (DX200T)

41739SK Bovendeel ventilatorhuis met schermplaat (CF20/CF20T)

41740SK Lijstwerk voor montageplaat (volledige reeks)

41741SK Trekkoordmontage (CF20/CF20T)

41742SK Rotor (volledige reeks)