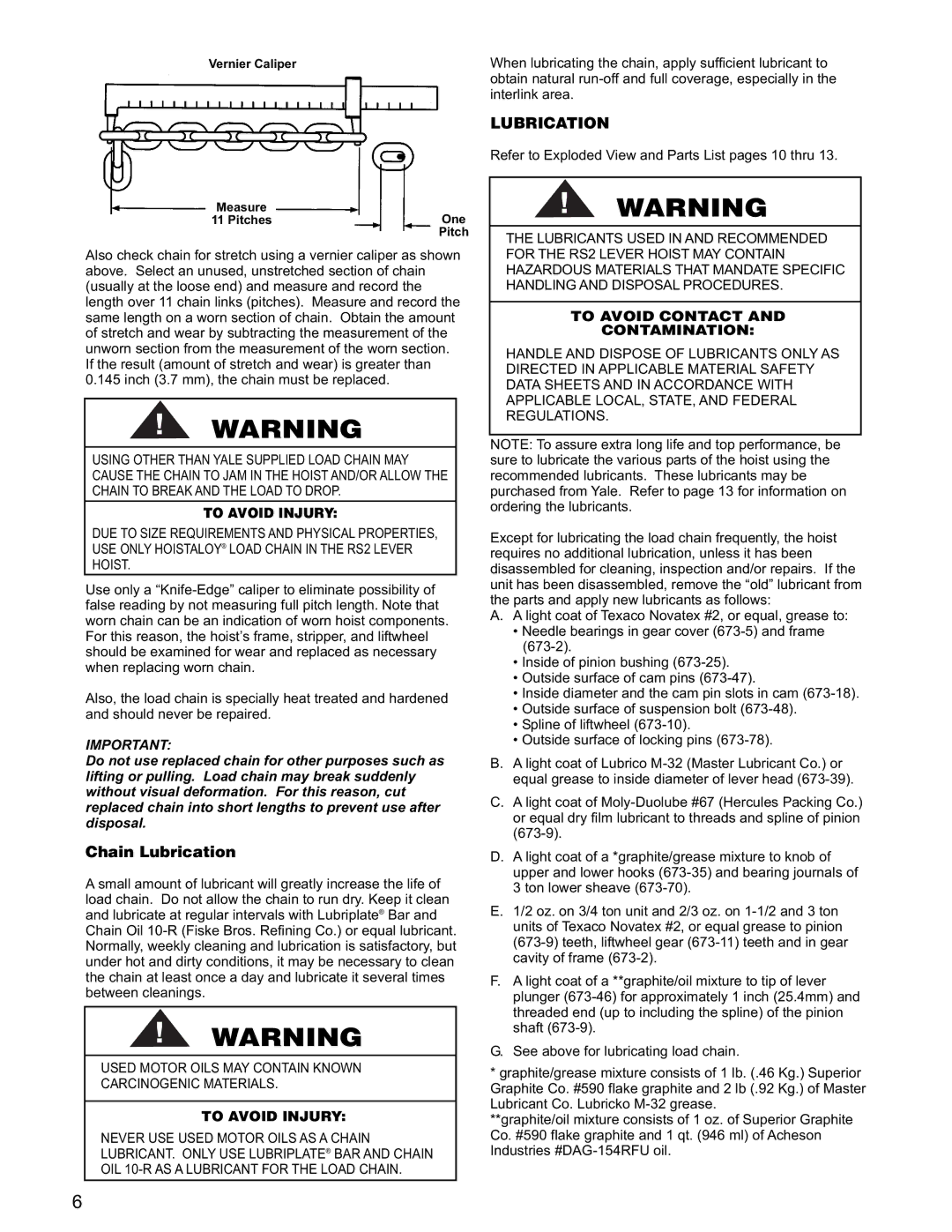

Vernier Caliper

Measure | One |

11 Pitches | |

| Pitch |

Also check chain for stretch using a vernier caliper as shown above. Select an unused, unstretched section of chain (usually at the loose end) and measure and record the length over 11 chain links (pitches). Measure and record the same length on a worn section of chain. Obtain the amount of stretch and wear by subtracting the measurement of the unworn section from the measurement of the worn section. If the result (amount of stretch and wear) is greater than 0.145 inch (3.7 mm), the chain must be replaced.

WARNING

USING OTHER THAN YALE SUPPLIED LOAD CHAIN MAY CAUSE THE CHAIN TO JAM IN THE HOIST AND/OR ALLOW THE CHAIN TO BREAK AND THE LOAD TO DROP.

TO AVOID INJURY:

DUE TO SIZE REQUIREMENTS AND PHYSICAL PROPERTIES, USE ONLY HOISTALOY® LOAD CHAIN IN THE RS2 LEVER HOIST.

Use only a

Also, the load chain is specially heat treated and hardened and should never be repaired.

IMPORTANT:

Do not use replaced chain for other purposes such as lifting or pulling. Load chain may break suddenly without visual deformation. For this reason, cut replaced chain into short lengths to prevent use after disposal.

Chain Lubrication

A small amount of lubricant will greatly increase the life of load chain. Do not allow the chain to run dry. Keep it clean and lubricate at regular intervals with Lubriplate® Bar and Chain Oil

When lubricating the chain, apply sufficient lubricant to obtain natural

LUBRICATION

Refer to Exploded View and Parts List pages 10 thru 13.

WARNING

THE LUBRICANTSUSED IN AND RECOMMENDED FOR THE RS2 LEVER HOIST MAYCONTAIN HAZARDOUSMATERIALS THATMANDATE SPECIFIC HANDLING AND DISPOSALPROCEDURES.

TO AVOID CONTACT AND

CONTAMINATION:

HANDLE AND DISPOSE OF LUBRICANTS ONLYAS DIRECTED IN APPLICABLE MATERIAL SAFETY DATASHEETS AND IN ACCORDANCE WITH APPLICABLE LOCAL, STATE, AND FEDERAL REGULATIONS.

NOTE: To assure extra long life and top performance, be sure to lubricate the various parts of the hoist using the recommended lubricants. These lubricants may be purchased from Yale. Refer to page 13 for information on ordering the lubricants.

Except for lubricating the load chain frequently, the hoist requires no additional lubrication, unless it has been disassembled for cleaning, inspection and/or repairs. If the unit has been disassembled, remove the “old” lubricant from the parts and apply new lubricants as follows:

A. A light coat of Texaco Novatex #2, or equal, grease to:

• Needle bearings in gear cover

• Inside of pinion bushing

• Outside surface of cam pins

• Inside diameter and the cam pin slots in cam

• Outside surface of suspension bolt

• Spline of liftwheel

• Outside surface of locking pins

B. A light coat of Lubrico

C. A light coat of

D. A light coat of a *graphite/grease mixture to knob of upper and lower hooks

E. 1/2 oz. on 3/4 ton unit and 2/3 oz. on

F. A light coat of a **graphite/oil mixture to tip of lever plunger

6

WARNING

USED MOTOR OILS MAY CONTAIN KNOWN CARCINOGENIC MATERIALS.

TO AVOID INJURY:

NEVER USE USED MOTOR OILS AS A CHAIN LUBRICANT. ONLY USE LUBRIPLATE® BAR AND CHAIN OIL

G. See above for lubricating load chain.

* graphite/grease mixture consists of 1 lb. (.46 Kg.) Superior Graphite Co. #590 flake graphite and 2 lb (.92 Kg.) of Master Lubricant Co. Lubricko

**graphite/oil mixture consists of 1 oz. of Superior Graphite Co. #590 flake graphite and 1 qt. (946 ml) of Acheson Industries