WARNING

USING ANY GREASE OR LUBRICANT ON THE BRAKING SURFACESWILL CAUSE BRAKE SLIPPAGEAND LOSS OF LOAD CONTROL WHICH MAY RESULTIN INJURY AND/OR PROPERTY DAMAGE.

TO AVOID INJURY:

DO NOT USE ANY GREASE OR LUBRICANT ON BRAKING SURFACES. THE BRAKE IS DESIGNED

When lubricating parts adjacent to the brake, DO NOT use an excessive amount of lubricant which could seep onto the brake surfaces.

EXTERIOR FINISH

The exterior surface of the RS2 Lever Hoist has a durable, scratch resistant baked powder coating. Normally, the exterior surfaces can be cleaned by wiping with a cloth. However, if the finish is damaged, compatible

PREVENTATIVE MAINTENANCE

A preventative maintenance program should be established to prolong the useful life of the hoist and maintain its reliability and continued safe use. The program should include frequent and periodic inspections (see page 5) with particular attention paid to lubrication of various components using the recommended lubricants (see Lubrication section for lubricating load chain and other parts).

RECOMMENDED SPARE PARTS

To insure continued operation, it is recommended that two friction discs (Key No.

DISASSEMBLY

When disassembling and assembling the RS2 Lever Hoist, refer to the exploded view and parts list on pages 10 thru 13. These show the proper relationship of the parts, part names and the required quantities of the parts. In addition, please observe the following:

A. The liftwheel gear

B. Needle bearings are pressed into the gear cover

C. If so equipped, do not attempt to disassemble the Load Limiter

If it is not functioning properly, the entire Load

Limiter must be replaced.

D. Refer to page 8 for removal and installation of load chain. E. The brake cover

ASSEMBLY

When reassembling the unit, lubricate the various parts as specified on page 6 and observe the following:

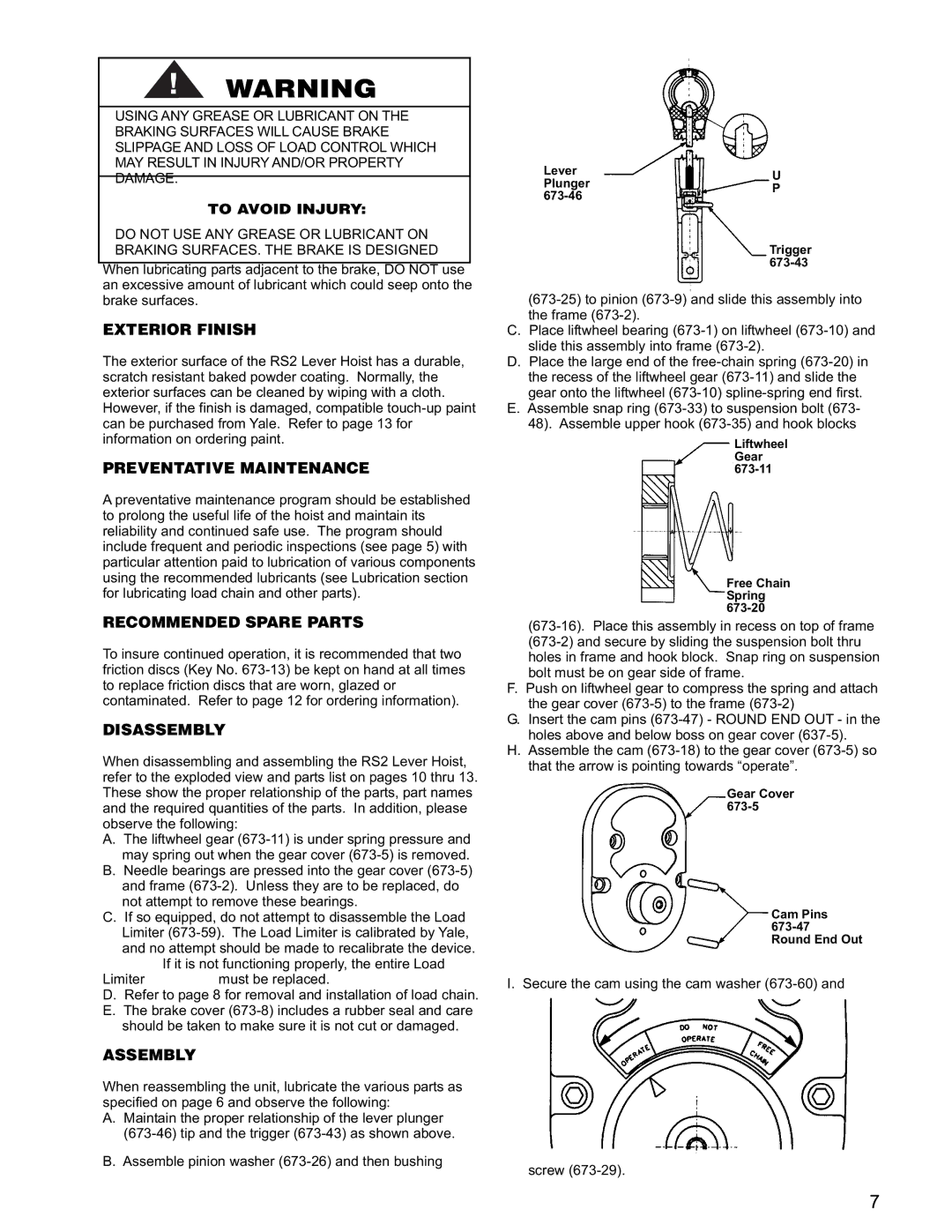

A. Maintain the proper relationship of the lever plunger

LeverU

PlungerP

Trigger

C. Place liftwheel bearing

D. Place the large end of the

E. Assemble snap ring

Liftwheel

Gear

Free Chain Spring

F. Push on liftwheel gear to compress the spring and attach the gear cover

G. Insert the cam pins

H. Assemble the cam

Gear Cover

Cam Pins

I. Secure the cam using the cam washer

B. Assemble pinion washer

screw

7