Inspection of hoists is divided into two general classifications designated as “frequent” and “periodic”.

Frequent Inspections

These inspections are by the operator or other designated personnel. Frequent inspections are to be performed daily or prior to each use and they are to include the following:

A. Check for free movement of the lever, trigger and cam. B. Operate hoist with no load and check for visual signs or abnormal noises that could indicate a potential problem.

C. Check brake for evidence of slippage.

D. Check chain for lubrication, wear damaged links or foreign material (see page 6).

E. Check hooks for damage, cracks, twist, latch engagement and latch operation (see below).

F. Check lever for bends, cracks and damage. G. Check support or anchor for damage.

Any deficiencies noted during the frequent inspections must be corrected before using the hoist.

Periodic Inspections

These are visual inspections by an appointed person who records conditions to provide a basis for a continuing evaluation of the hoist. Periodic inspections are to be performed

A. All items listed under frequent inspections. B. Evidence of loose screws.

C. Evidence of worn, corroded, cracked or distorted upper and lower hook blocks, frame, end ring, hook block screws, covers, lever, suspension bolt, gears, bearings, pawls, pawl springs, cam, cam pins, lever cover, free- chaining spring, ratchet hub, stripper, Load Limiter (if equipped with same), ratchet and hoist hanger.

D. Evidence of worn, glazed or oil contaminated friction discs. Friction discs should be replaced if their thickness is less than .075 inch (2 mm).

E. Warning label for legibility.

NOTE: To perform some of the periodic inspections, it is necessary to partially disassemble the hoist. Refer to

Any deficiencies noted during the periodic inspection must be corrected before using the hoist.

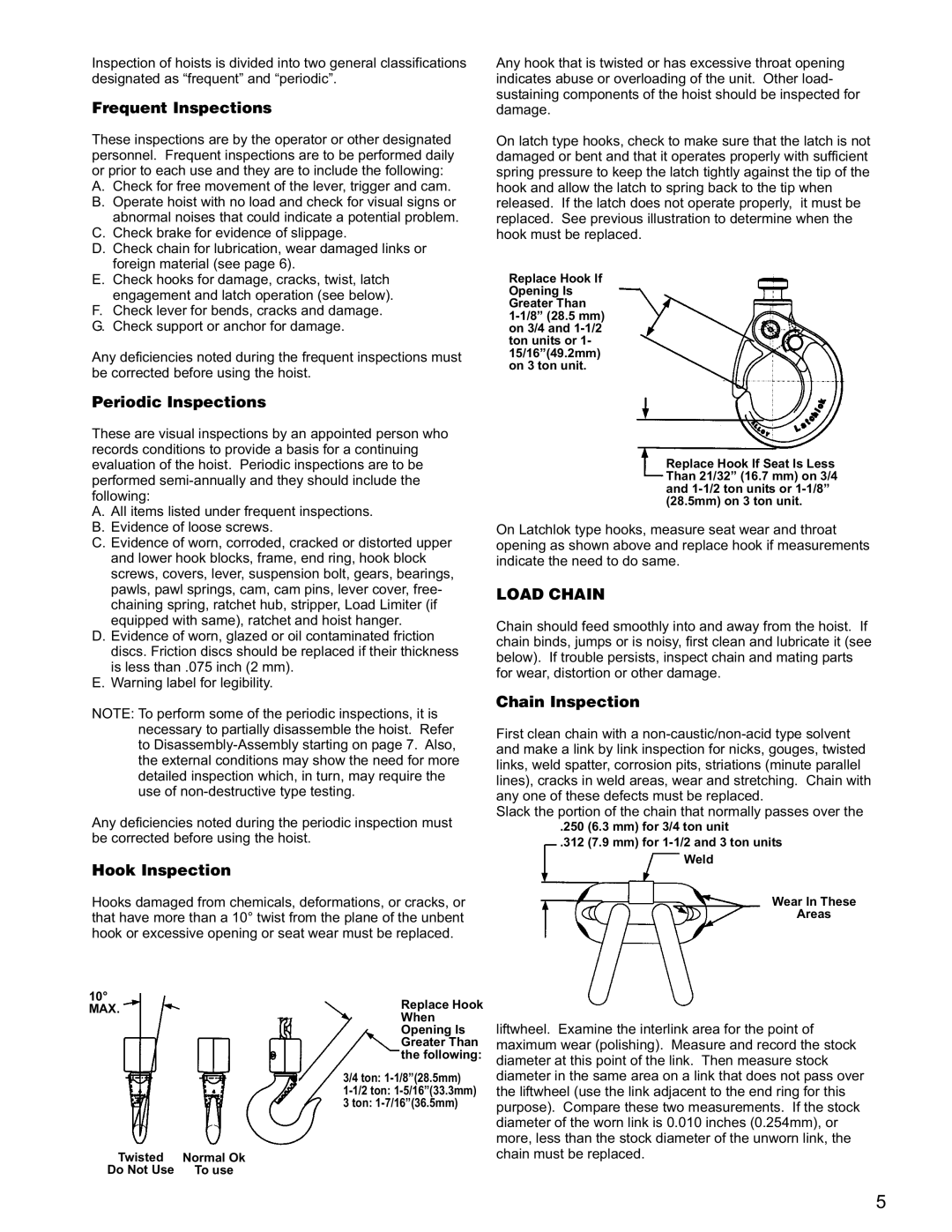

Hook Inspection

Hooks damaged from chemicals, deformations, or cracks, or that have more than a 10° twist from the plane of the unbent hook or excessive opening or seat wear must be replaced.

Any hook that is twisted or has excessive throat opening indicates abuse or overloading of the unit. Other load- sustaining components of the hoist should be inspected for damage.

On latch type hooks, check to make sure that the latch is not damaged or bent and that it operates properly with sufficient spring pressure to keep the latch tightly against the tip of the hook and allow the latch to spring back to the tip when released. If the latch does not operate properly, it must be replaced. See previous illustration to determine when the hook must be replaced.

Replace Hook If Opening Is Greater Than

Replace Hook If Seat Is Less Than 21/32” (16.7 mm) on 3/4 and

On Latchlok type hooks, measure seat wear and throat opening as shown above and replace hook if measurements indicate the need to do same.

LOAD CHAIN

Chain should feed smoothly into and away from the hoist. If chain binds, jumps or is noisy, first clean and lubricate it (see below). If trouble persists, inspect chain and mating parts for wear, distortion or other damage.

Chain Inspection

First clean chain with a

Slack the portion of the chain that normally passes over the

.250 (6.3 mm) for 3/4 ton unit

.312 (7.9 mm) for

Wear In These

Areas

10°

MAX.

Twisted | Normal Ok |

Do Not Use | To use |

Replace Hook When Opening Is Greater Than the following:

3/4 ton:

3 ton:

liftwheel. Examine the interlink area for the point of maximum wear (polishing). Measure and record the stock diameter at this point of the link. Then measure stock diameter in the same area on a link that does not pass over the liftwheel (use the link adjacent to the end ring for this purpose). Compare these two measurements. If the stock diameter of the worn link is 0.010 inches (0.254mm), or more, less than the stock diameter of the unworn link, the chain must be replaced.

5