J.Assemble pawls (673-19) to pawl shafts (673-22) and secure with snap rings (673-32). Place pawl springs

(673-21) on pawl shafts and insert these assemblies into frame (673-2).

K.Slide friction hub (673-12) onto pinion (673-9) and place one friction disc (673-13) on top of friction hub.

Frame

673-2Pawl Shaft

673-22

Pawl Snap

Ring

673-32

PawlPawl

Spring673-19 673-21

Assemble ratchet bushing (673-24) to ratchet (673-23). Spring apart pawls and slide ratchet/bushing assembly on friction hub as shown below.

L. To assemble and adjust the brake, place the second friction disc (673-13) on top of the ratchet. Thread the

| Ratchet Bushing |

Frame | 673-24 |

Ratchet |

673-2 | 673-23 |

| Pawl Assembly |

ratchet hub (673-14) or Load Limiter (673-59) onto the pinion (673-9). Insert the two locking pins (673-78) into the holes of the ratchet hub or Load Limiter. Holding the pinion steady, rotate the ratchet hub or Load Limiter from the stop in the full clockwise position to the stop in the full counterclockwise position. From stop to stop there should be 10 to 45° of rotation. If the rotation does not fall within this range, remove the locking pins, ratchet hub or Load Limiter, pawl assemblies (see step J), friction discs, ratchet and ratchet bushing. Slide the friction hub partially off of the pinion until the splines disengage. Rotate the friction hub slightly clockwise if the rotation is more than 45° or counterclockwise if the rotation is less than 10°. Repeat steps 1-4 until the rotation from stop to stop is 10 to 45°. Note: The ratchet hub or Load Limiter can be started onto the thread of the pinion in one of four poisons. Each time the ratchet hub or Load Limiter is threaded onto the pinion, maintain the same orientation. Install the pawl assemblies per step K.

M. Assemble the snap ring (673-31) to the stripper pin (673- 34). Slide the stripper (673-15) into the recess in the bottom of the frame and secure by sliding the stripper pin thru the holes in the frame and stripper.

N. Assemble brake cover (673-8) to frame.

O. Assemble the lever assembly (step A) to ratchet hub (673-14) or Load Limiter (673-59) and secure by attaching the lever cover (673-17) to the ratchet hub or Load Limiter.

P. Install load chain (673-52) - see removal and installation of load chain.

Q. After assembly, test the unit as indicated on page 9.

REMOVAL OF LOAD CHAIN

A.Remove the lower hook block assembly from the load chain on the 3/4 and 1-1/2 ton units. On the 3 ton unit,

disengage the load chain from the hoist hanger (673-75)

8 by removing the dead end pin (673-76).

B.Put unit in free-chaining - see page 2

C.Pull on the end ring (673-53) and pull the chain out of the hoist (and out of the lower hook block on the 3 ton unit).

D.Remove the end ring from the load chain.

INSTALLING LOAD CHAIN

3/4 ton unit uses 1/4 in.(6.3mm) stock disc grade load

WARNING

IMPROPER INSTALLATION (REEVING) OF THE LOAD CHAIN CAN RESULT IN A DROPPED LOAD.

TO AVOID INJURY:

• VERIFY USE OF PROPER SIZE AND TYPE OF LOAD CHAIN FOR SPECIFIC RS2 LEVER HOIST.

• INSTALL LOAD CHAIN PROPERLYAS INDICATED BELOW

chain.

1-1/2 and 3 ton units use 5/16 in.(7.9mm) stock disc

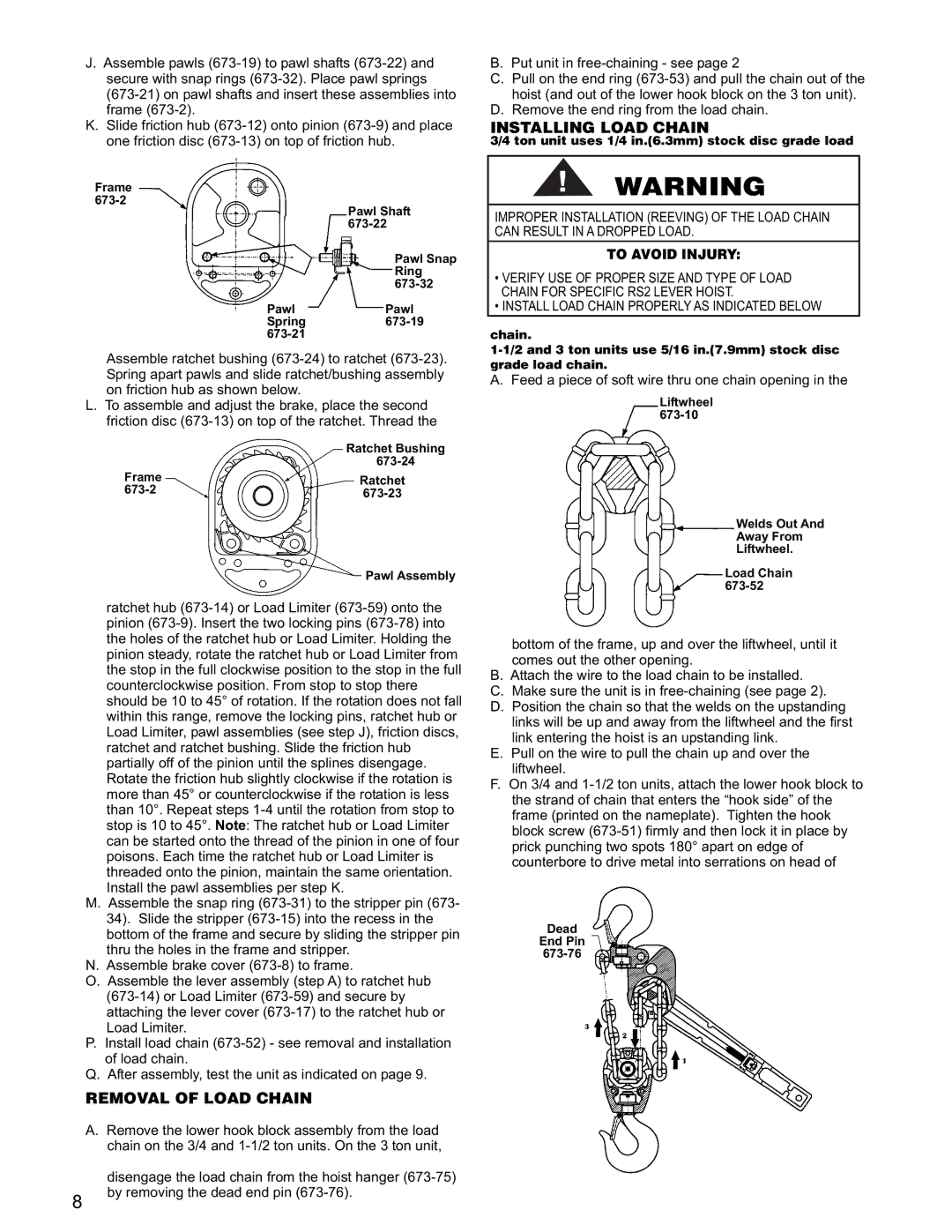

Agrad. Feedloadpiecechainof. soft wire thru one chain opening in the

Liftwheel 673-10

Welds Out And Away From Liftwheel.

Load Chain 673-52

bottom of the frame, up and over the liftwheel, until it comes out the other opening.

B. Attach the wire to the load chain to be installed.

C. Make sure the unit is in free-chaining (see page 2). D. Position the chain so that the welds on the upstanding

links will be up and away from the liftwheel and the first link entering the hoist is an upstanding link.

E. Pull on the wire to pull the chain up and over the liftwheel.

F. On 3/4 and 1-1/2 ton units, attach the lower hook block to the strand of chain that enters the “hook side” of the frame (printed on the nameplate). Tighten the hook block screw (673-51) firmly and then lock it in place by prick punching two spots 180° apart on edge of counterbore to drive metal into serrations on head of

Dead

End Pin

673-76