|

| |||

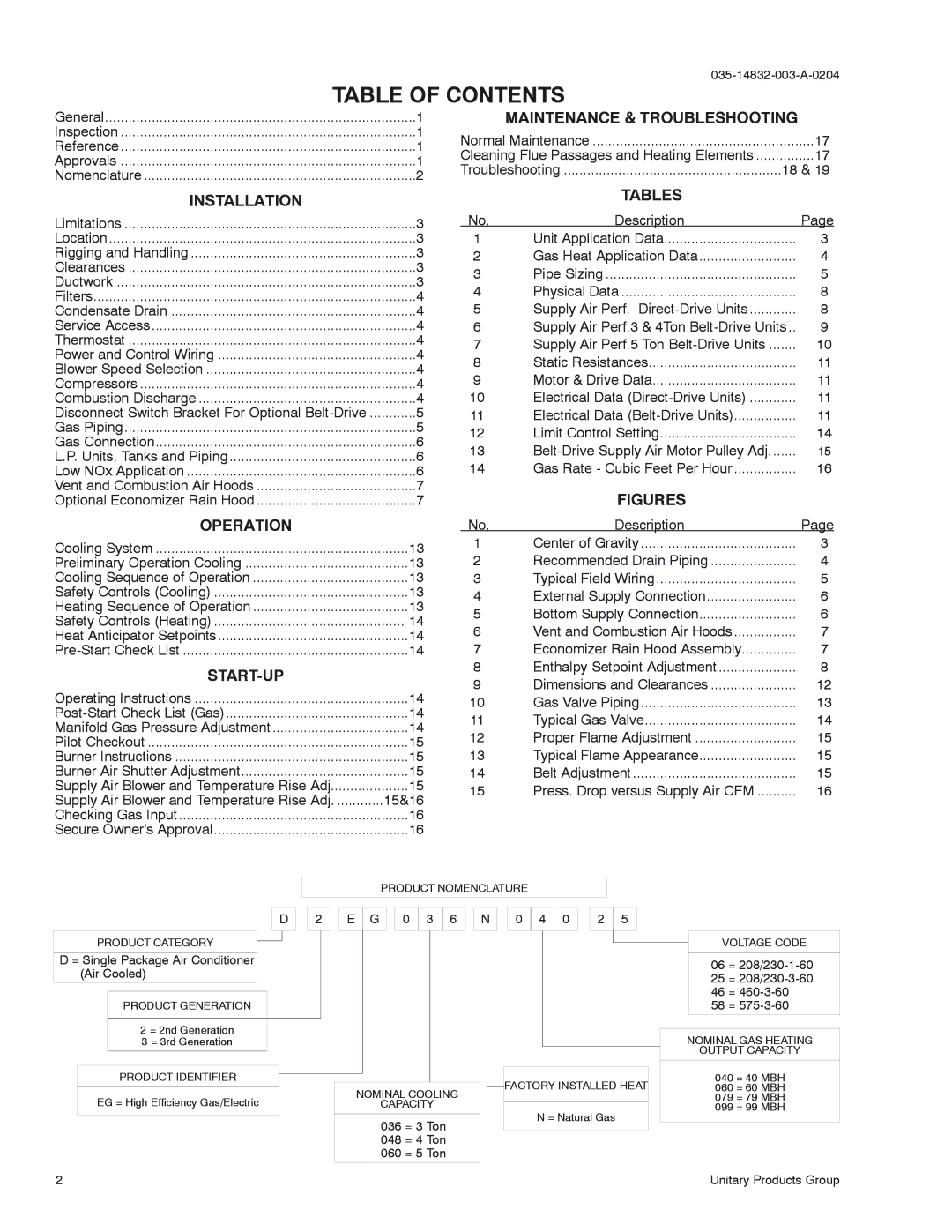

| TABLE OF CONTENTS |

| ||

General | 1 | MAINTENANCE & TROUBLESHOOTING | ||

Inspection | 1 | Normal Maintenance | 17 | |

Reference | 1 | |||

Cleaning Flue Passages and Heating Elements | 17 | |||

Approvals | 1 | |||

Troubleshooting | 18 & 19 | |||

Nomenclature | 2 | |||

|

| |||

INSTALLATION |

|

Limitations | 3 |

Location | 3 |

Rigging and Handling | 3 |

Clearances | 3 |

Ductwork | 3 |

Filters | 4 |

Condensate Drain | 4 |

Service Access | 4 |

Thermostat | 4 |

Power and Control Wiring | 4 |

Blower Speed Selection | 4 |

Compressors | 4 |

Combustion Discharge | 4 |

Disconnect Switch Bracket For Optional | 5 |

Gas Piping | 5 |

Gas Connection | 6 |

L.P. Units, Tanks and Piping | 6 |

Low NOx Application | 6 |

Vent and Combustion Air Hoods | 7 |

Optional Economizer Rain Hood | 7 |

OPERATION |

|

Cooling System | 13 |

Preliminary Operation Cooling | 13 |

Cooling Sequence of Operation | 13 |

Safety Controls (Cooling) | 13 |

Heating Sequence of Operation | 13 |

Safety Controls (Heating) | 14 |

Heat Anticipator Setpoints | 14 |

14 | |

| |

Operating Instructions | 14 |

14 | |

Manifold Gas Pressure Adjustment | 14 |

Pilot Checkout | 15 |

Burner Instructions | 15 |

Burner Air Shutter Adjustment | 15 |

Supply Air Blower and Temperature Rise Adj | 15 |

Supply Air Blower and Temperature Rise Adj | 15&16 |

Checking Gas Input | 16 |

Secure Owner's Approval | 16 |

| TABLES |

|

No. | Description | Page |

1 | Unit Application Data | 3 |

2 | Gas Heat Application Data | 4 |

3 | Pipe Sizing | 5 |

4 | Physical Data | 8 |

5 | Supply Air Perf. | 8 |

6 | Supply Air Perf.3 & 4Ton | 9 |

7 | Supply Air Perf.5 Ton | 10 |

8 | Static Resistances | 11 |

9 | Motor & Drive Data | 11 |

10 | Electrical Data | 11 |

11 | Electrical Data | 11 |

12 | Limit Control Setting | 14 |

13 | 15 | |

14 | Gas Rate - Cubic Feet Per Hour | 16 |

| FIGURES |

|

No. | Description | Page |

1 | Center of Gravity | 3 |

2 | Recommended Drain Piping | 4 |

3 | Typical Field Wiring | 5 |

4 | External Supply Connection | 6 |

5 | Bottom Supply Connection | 6 |

6 | Vent and Combustion Air Hoods | 7 |

7 | Economizer Rain Hood Assembly | 7 |

8 | Enthalpy Setpoint Adjustment | 8 |

9 | Dimensions and Clearances | 12 |

10 | Gas Valve Piping | 13 |

11 | Typical Gas Valve | 14 |

12 | Proper Flame Adjustment | 15 |

13 | Typical Flame Appearance | 15 |

14 | Belt Adjustment | 15 |

15 | Press. Drop versus Supply Air CFM | 16 |

D

PRODUCT CATEGORY

D = Single Package Air Conditioner (Air Cooled)

PRODUCT GENERATION

2 = 2nd Generation

3 = 3rd Generation

PRODUCT IDENTIFIER

EG = High Efficiency Gas/Electric

2

PRODUCT NOMENCLATURE

2 ![]()

![]() E

E ![]() G

G ![]()

![]() 0

0 ![]()

![]() 3

3 ![]() 6

6 ![]()

![]() N

N ![]()

![]() 0

0 ![]() 4

4 ![]() 0

0 ![]()

![]() 2

2 ![]()

![]() 5

5

|

|

| FACTORY INSTALLED HEAT |

NOMINAL COOLING |

|

|

|

CAPACITY |

|

|

|

|

| N = Natural Gas | |

|

|

| |

036 = 3 Ton |

|

| |

|

|

| |

048 = 4 Ton |

|

|

|

060 = 5 Ton |

|

|

|

VOLTAGE CODE

06 =

25 =

46 =

58 =

NOMINAL GAS HEATING

OUTPUT CAPACITY

040 = 40 MBH

060 = 60 MBH

079 = 79 MBH

099 = 99 MBH

Unitary Products Group