COOLING / HEATING (24 VOLT THERMOSTAT)

COOLING/HEATING(24VOLTTHERMOSTAT)

THERMOSTAT1

TERMINALS

| UNITTERMINAL |

|

RH | STRIPTB1 |

|

ADD |

| |

|

| |

JUMPER RC | R |

|

Y | Y1 | 24VOLT |

|

|

TRANSFORMER

Y2

WW1

W2

GG

B

124VOLTTHERMOSTAT2TH07701024.IFTHEUNITHASANECONOMIZER, REMOVEJUMPERJ1FROMTERMINALS8AND10ONTHERELAYBOARD TOPREVENTSIMULTANEOUSOPERATIONOFTHECOMPRESSORAND THEECONOMIZER.IFYOUWANTTOCONTROLTHERECONOMIZERONA SECONDSTAGEOFCOOLINGORHAVEANDELECTRICHEATACCESSORY WITHTWOSTAGESOFHEAT,USETHERMOSTAT2TH0471024

COOLING/HEATING(ELECTRONICTHERMOSTAT)

SINGLESTAGE

THERMOSTAT1

TERMINALS UNITTERMINAL

RH STRIPTB1

| RC |

| R |

ADD |

|

|

|

Y |

| Y1 | |

JUMPER |

|

|

|

W |

| W1 | |

|

| ||

|

|

|

|

| G |

| G |

|

|

|

|

|

|

| B |

|

|

|

|

24VOLT

TRANSFORMER

1ELECTRONICPROGRAMMABLETHERMOSTAT2ET07701024(INCLUDESSUBBASE).

IFTHISUNITHASANDECONOMIZER,REMOVEJUMPERJ1FROMTERMINALS8AND 10ONTHERELAYBOARDTOPREVENTSIMULTANEOUSOPERATIONOFTHE COMPRESSORANDTHEECONOMIZER.IFYOUWANTTOCONTROLTHE ECONOMIZERONASECONDSTAGEOFCOOLING,USETHERMOSTAT2ET04700224.

REFER TO THE ELECTRICAL

DATA TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION

CONTROL WIRING

COOLING / HEATING (ELECTRONIC THERMOSTAT)

THERMOSTAT1 |

|

|

| ||

TERMINALS |

| UNITTERMINAL |

| ||

| RC |

|

| STRIPTB1 | 24VOLT |

ADD |

|

|

| ||

RH |

|

| R | TRANSFORMER | |

JUMPER |

|

| |||

|

|

|

|

| |

| Y1 |

|

| Y1 |

|

| Y2 | 2 | 2 | Y2 |

|

| W1 |

|

| W1 |

|

4 | W2 |

| 3 | W2 |

|

| G |

|

| G |

|

| B |

|

| B |

|

| LED1 |

|

| X |

|

| LED2 | NOT |

| N |

|

| COM | USED 4 |

|

| |

ADD | A1 | 3 |

|

|

|

|

|

|

| ||

JUMPER | A2 |

|

|

| |

T TOREMOTESENSOR

TOREMOTESENSOR

T 2TH040702224IFUSED

2TH040702224IFUSED

1ELECTRONICPROGRAMMABLETHERMOSTAT2ET04700224(INCLUDESSUBBASE)

2SECONDSTAGECOOLINGISNOTREQUIREDONUNITSLESSECONOMIZER.

3SECONDSTAGEHEATINGISONLYREQUIREDONUNITSWITHATWOSTAGE ELECTRICHEATER.

4REMOVEJUMBERJ2FROMTERMINALS4AND9ONJUMPERPLUGCONNECTOR P6ONUNITSWITHECONMIZER.TERMINALSA1ANDA2PROVIDEARELAY

POWER WIRING

REFER TO THE ELECTRICAL

DATA TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION

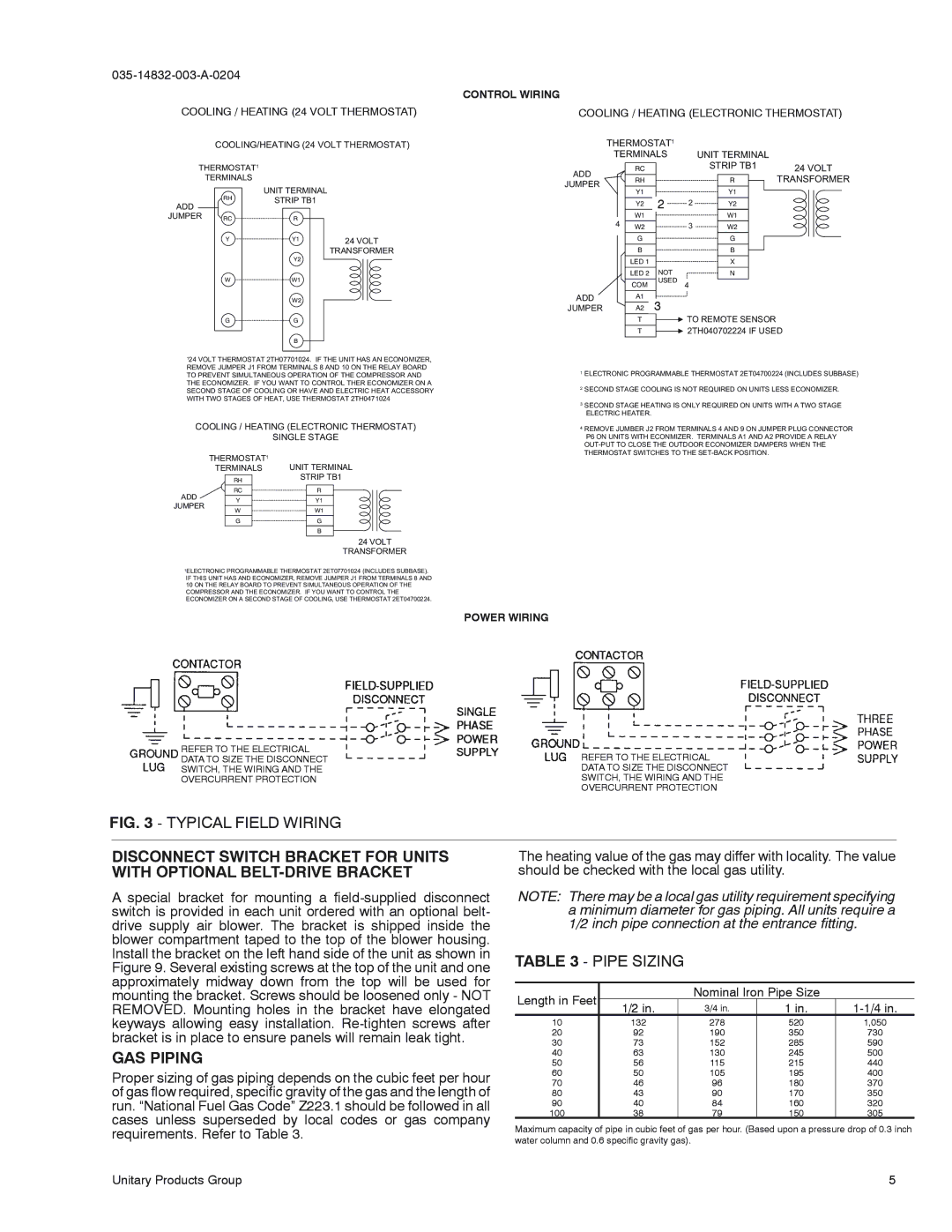

FIG. 3 - TYPICAL FIELD WIRING

DISCONNECT SWITCH BRACKET FOR UNITS | The heating value of the gas may differ with locality. The value | |||||||

WITH OPTIONAL | should be checked with the local gas utility. |

| ||||||

A special bracket for mounting a | NOTE: There may be a local gas utility requirement specifying | |||||||

switch is provided in each unit ordered with an optional belt- |

| a minimum diameter for gas piping. All units require a | ||||||

drive supply air blower. The bracket is shipped inside the |

| 1/2 inch pipe connection at the entrance fitting. | ||||||

blower compartment taped to the top of the blower housing. |

|

|

|

|

|

|

| |

Install the bracket on the left hand side of the unit as shown in | TABLE 3 - PIPE SIZING |

|

|

| ||||

Figure 9. Several existing screws at the top of the unit and one |

|

|

| |||||

|

|

|

|

|

|

| ||

approximately midway down from the top will be used for |

|

|

|

|

|

|

| |

mounting the bracket. Screws should be loosened only - NOT | Length in Feet |

|

| Nominal Iron Pipe Size |

| |||

REMOVED. Mounting holes in the bracket have elongated | 1/2 in. |

| 3/4 in. | 1 in. | ||||

|

|

| ||||||

keyways allowing easy installation. | 10 |

| 132 |

| 278 | 520 | 1,050 | |

bracket is in place to ensure panels will remain leak tight. | 20 |

| 92 |

| 190 | 350 | 730 | |

30 |

| 73 |

| 152 | 285 | 590 | ||

GAS PIPING | 40 |

| 63 |

| 130 | 245 | 500 | |

50 |

| 56 |

| 115 | 215 | 440 | ||

Proper sizing of gas piping depends on the cubic feet per hour | 60 |

| 50 |

| 105 | 195 | 400 | |

70 |

| 46 |

| 96 | 180 | 370 | ||

of gas flow required, specific gravity of the gas and the length of | 80 |

| 43 |

| 90 | 170 | 350 | |

run. “National Fuel Gas Code” Z223.1 should be followed in all | 90 |

| 40 |

| 84 | 160 | 320 | |

100 |

| 38 |

| 79 | 150 | 305 | ||

cases unless superseded by local codes or gas company |

|

| ||||||

Maximum capacity of pipe in cubic feet of gas per hour. (Based upon a pressure drop of 0.3 inch | ||||||||

requirements. Refer to Table 3. | ||||||||

water column and 0.6 specific gravity gas). |

|

|

| |||||

|

|

|

| |||||

Unitary Products Group | 5 |