MA6

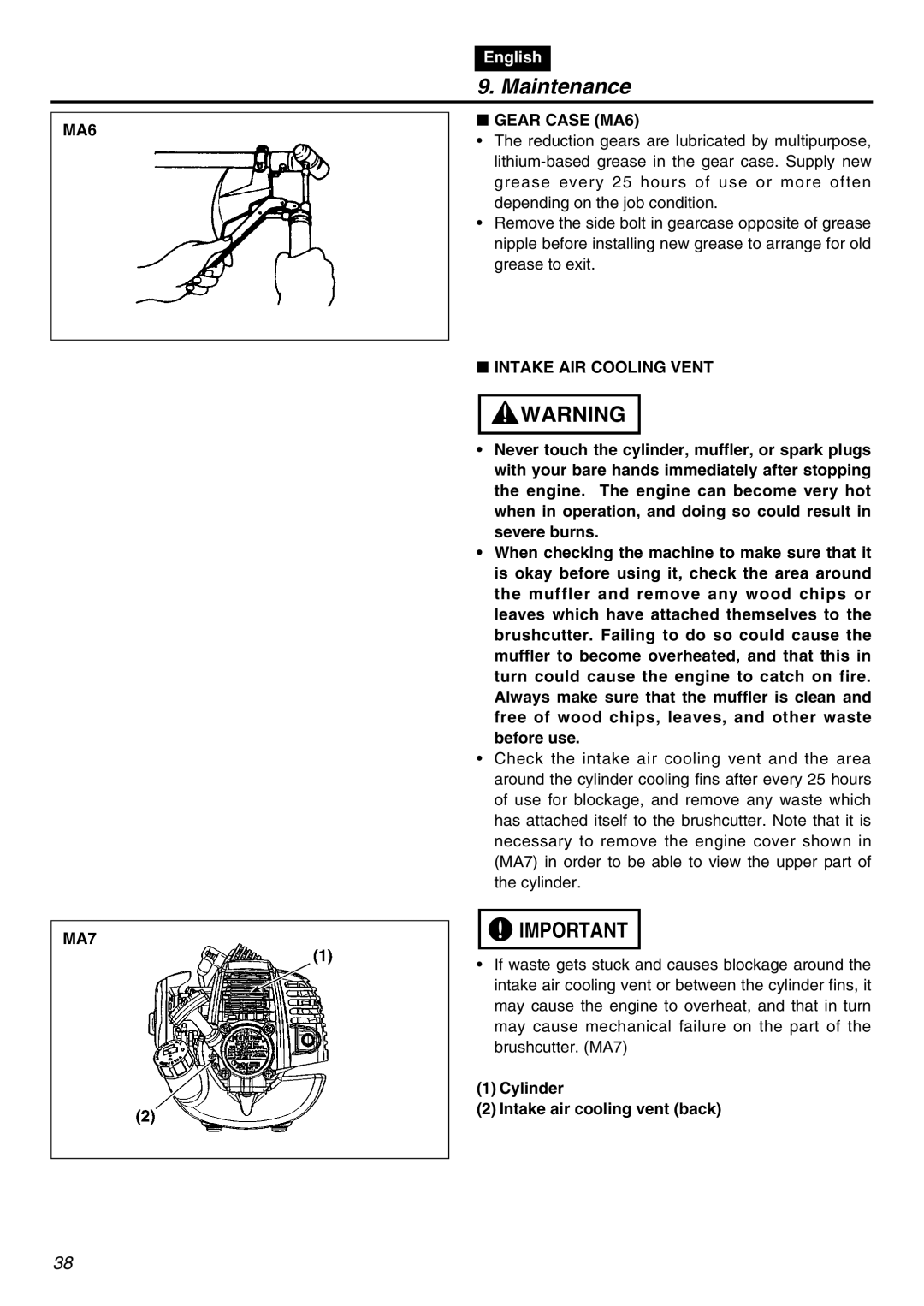

MA7

English

9. Maintenance

■GEAR CASE (MA6)

•The reduction gears are lubricated by multipurpose,

•Remove the side bolt in gearcase opposite of grease nipple before installing new grease to arrange for old grease to exit.

■INTAKE AIR COOLING VENT

![]() WARNING

WARNING

•Never touch the cylinder, muffler, or spark plugs with your bare hands immediately after stopping the engine. The engine can become very hot when in operation, and doing so could result in severe burns.

•When checking the machine to make sure that it is okay before using it, check the area around the muffler and remove any wood chips or leaves which have attached themselves to the brushcutter. Failing to do so could cause the muffler to become overheated, and that this in turn could cause the engine to catch on fire. Always make sure that the muffler is clean and free of wood chips, leaves, and other waste before use.

•Check the intake air cooling vent and the area around the cylinder cooling fins after every 25 hours of use for blockage, and remove any waste which has attached itself to the brushcutter. Note that it is necessary to remove the engine cover shown in (MA7) in order to be able to view the upper part of the cylinder.

![]()

![]() IMPORTANT

IMPORTANT

•If waste gets stuck and causes blockage around the intake air cooling vent or between the cylinder fins, it may cause the engine to overheat, and that in turn may cause mechanical failure on the part of the brushcutter. (MA7)

(1)Cylinder

(2)Intake air cooling vent (back)

38