SECTION 5: SERVICE PROCEDURES

REPLACING THE CHEMICAL FEEDER PUMP MOTOR (CONTINUED)

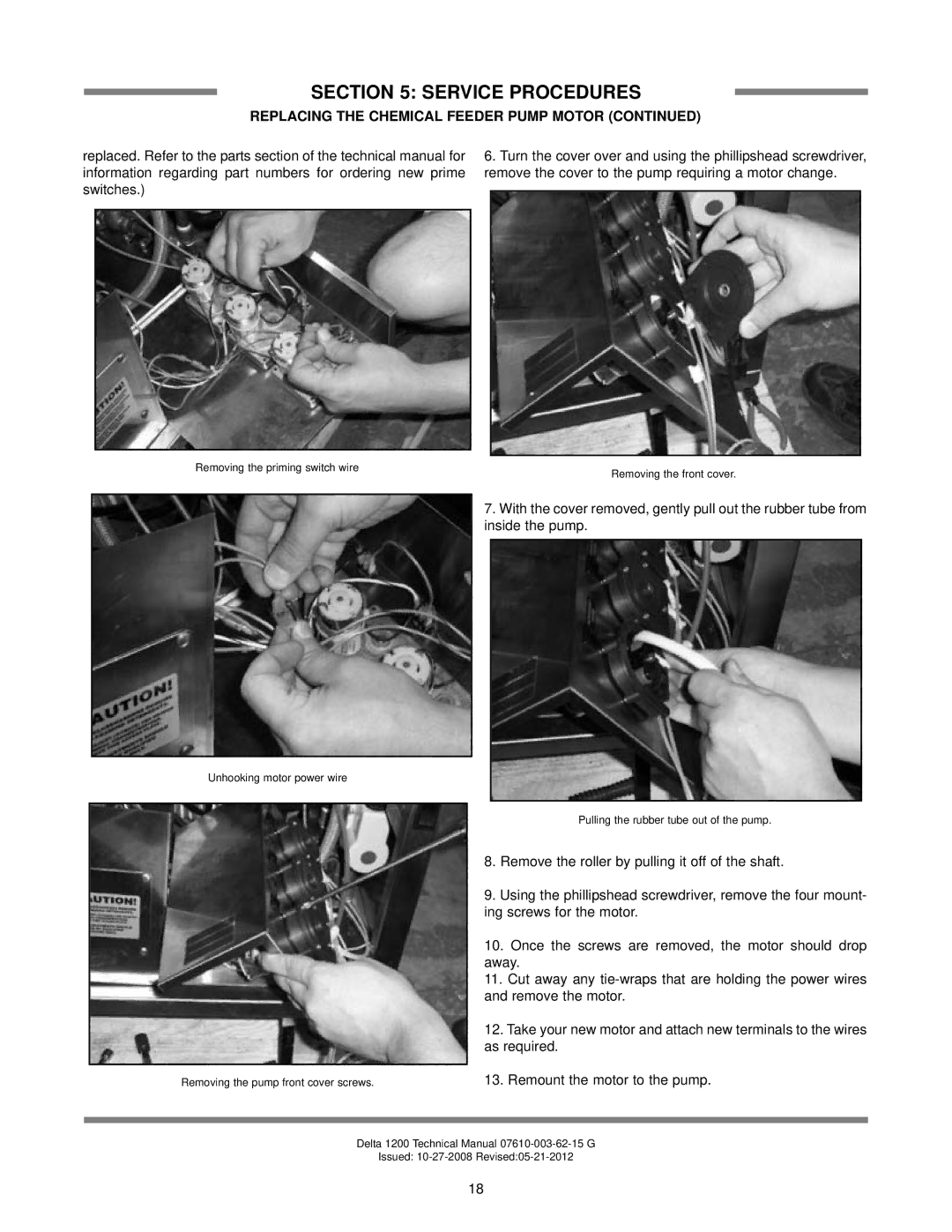

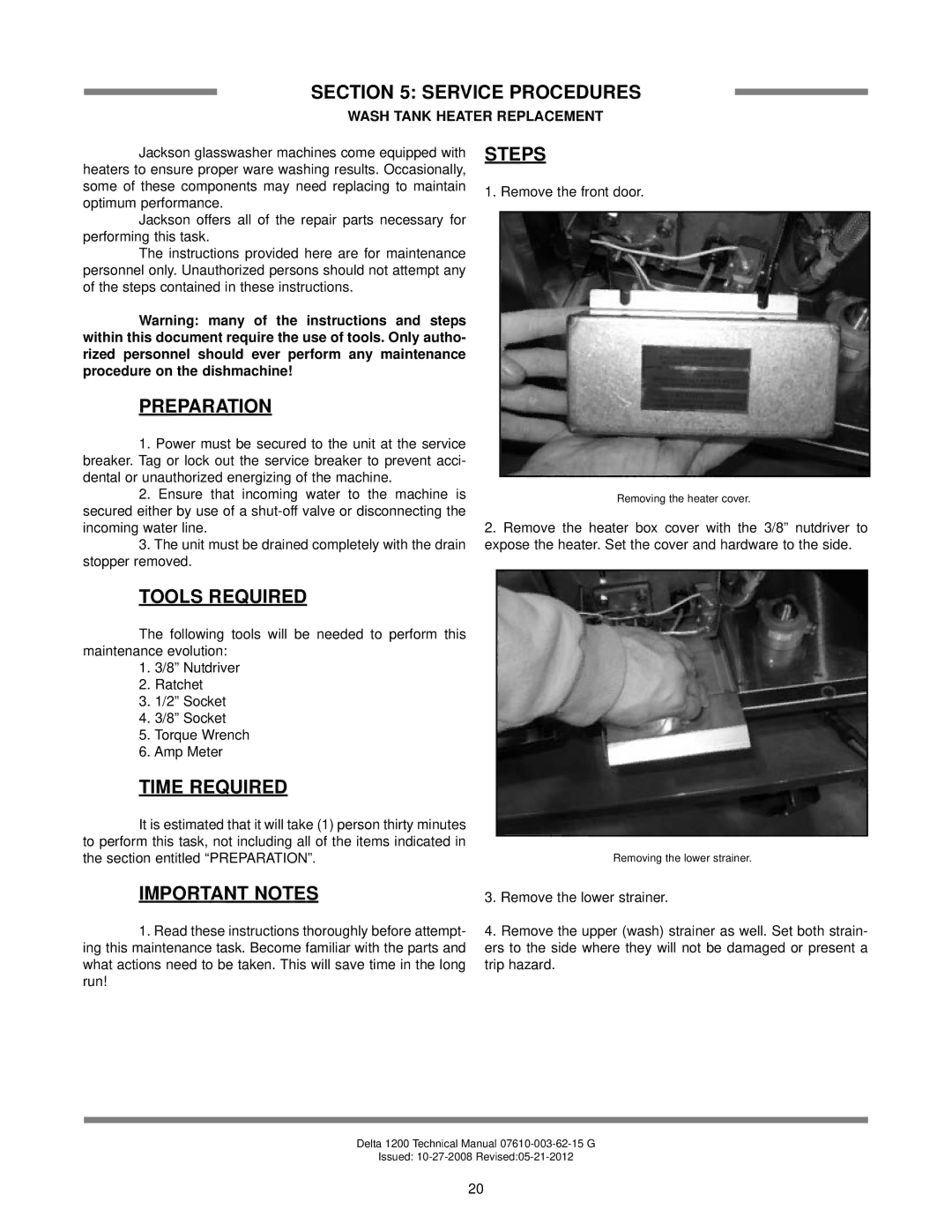

14.Place the roller and the rubber tube back in the pump cas- ing. Place the pump cover back on and tighten down with the four screws you previously removed.

15.Reattach the power wire and the wire for the priming switch.

16.Put the cover back on the control box and secure with the two screws previously removed.

17.Ensuring that all

area, restore power to the unit. Turn the unit on and by using the priming switch, verify that the feeder pump operates and pumps fluid.

18. Replace the front door.

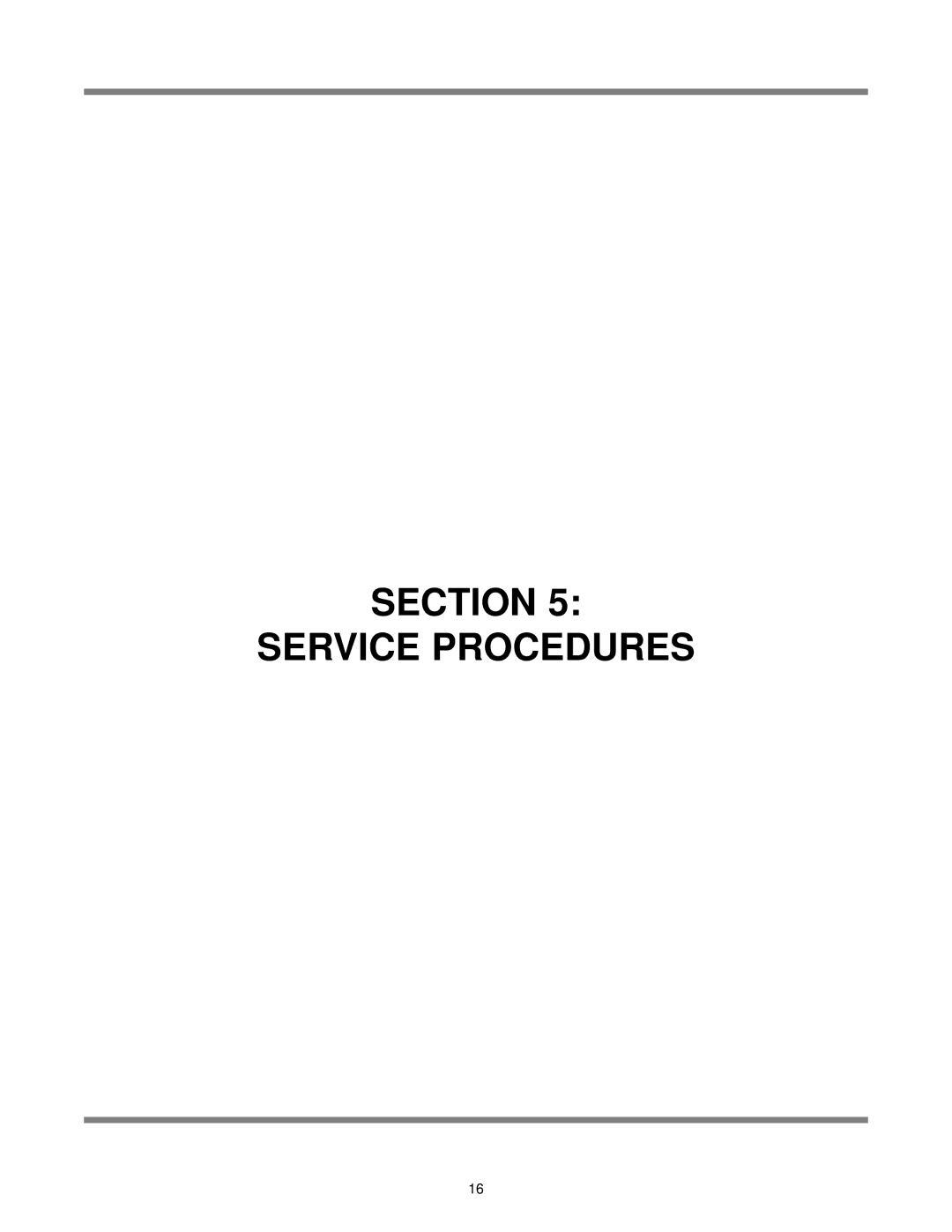

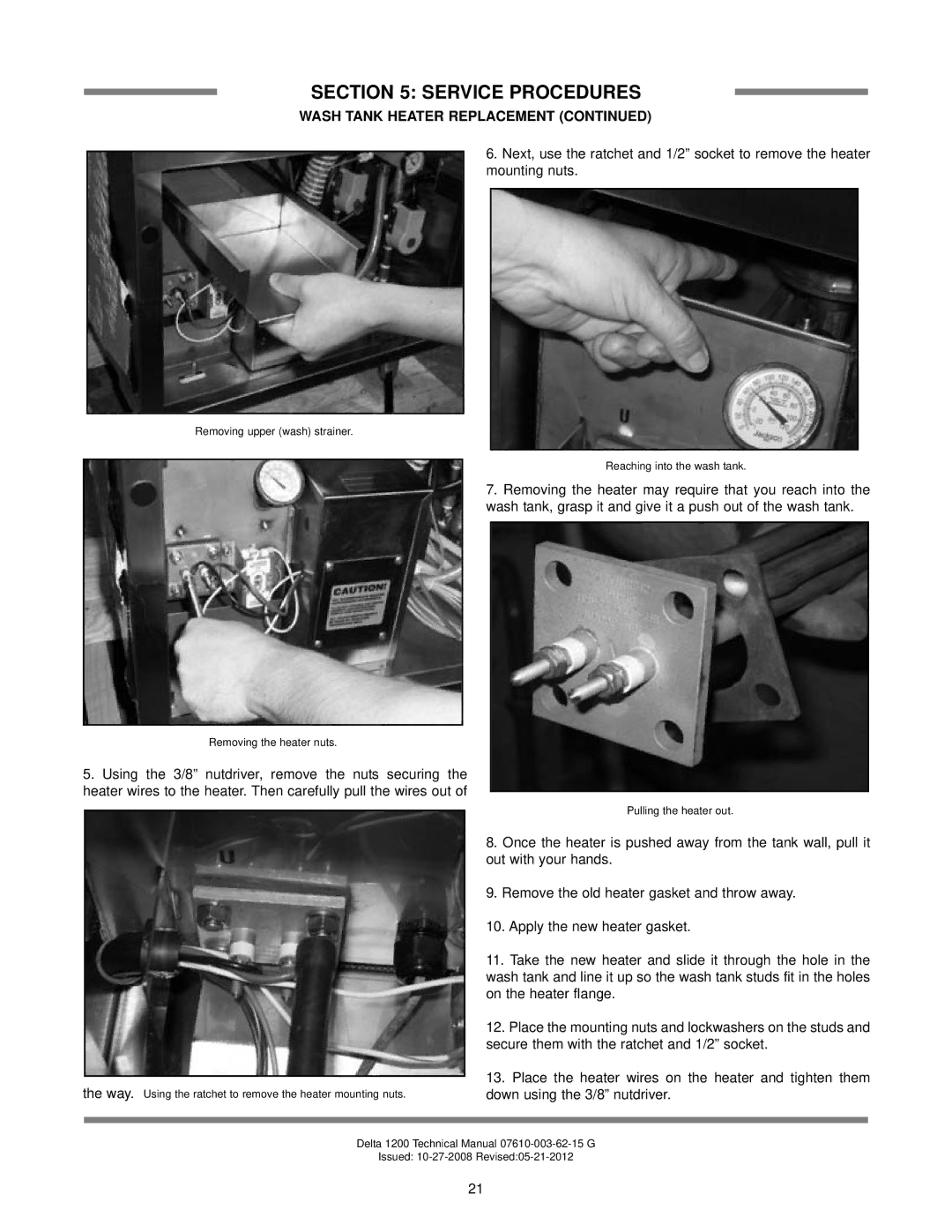

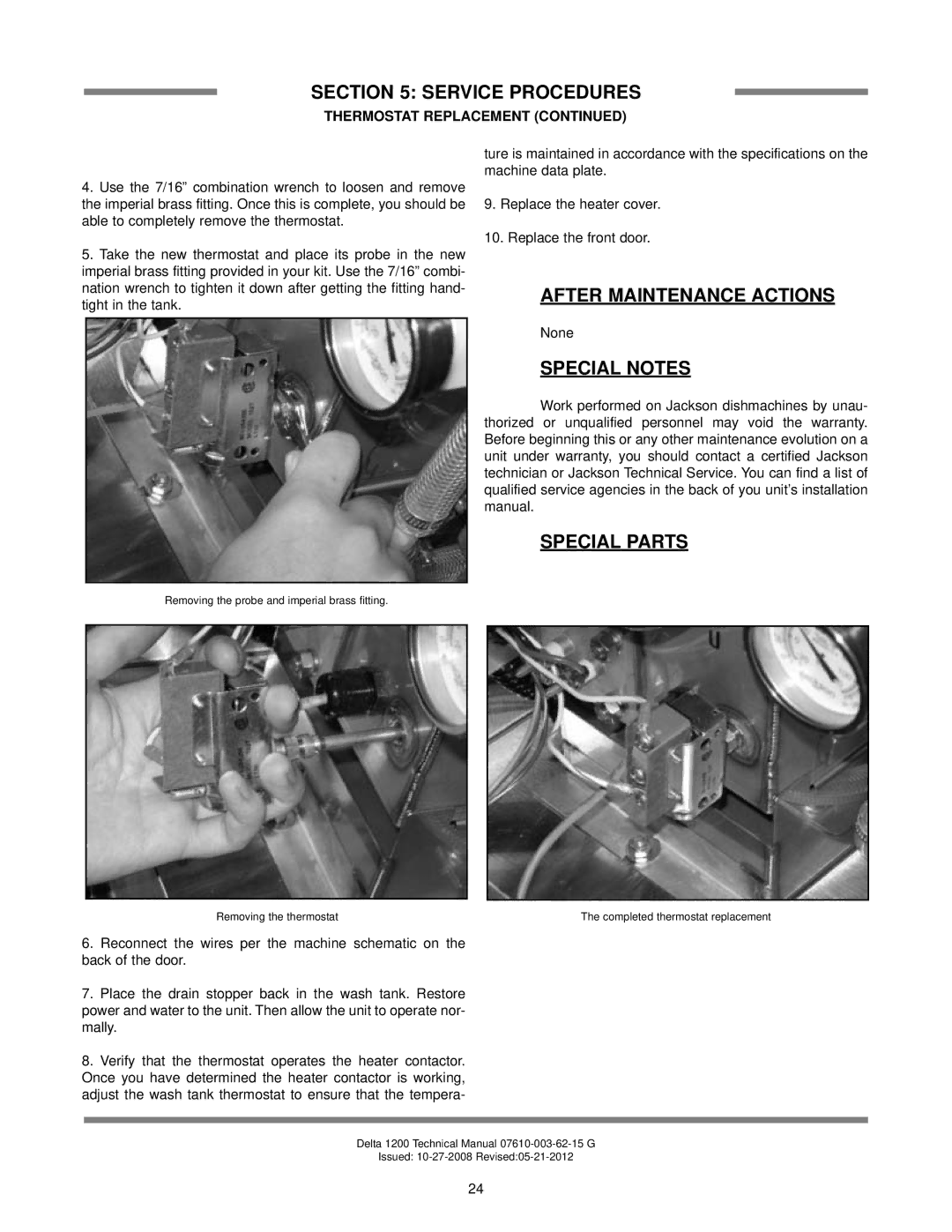

Removing the roller.

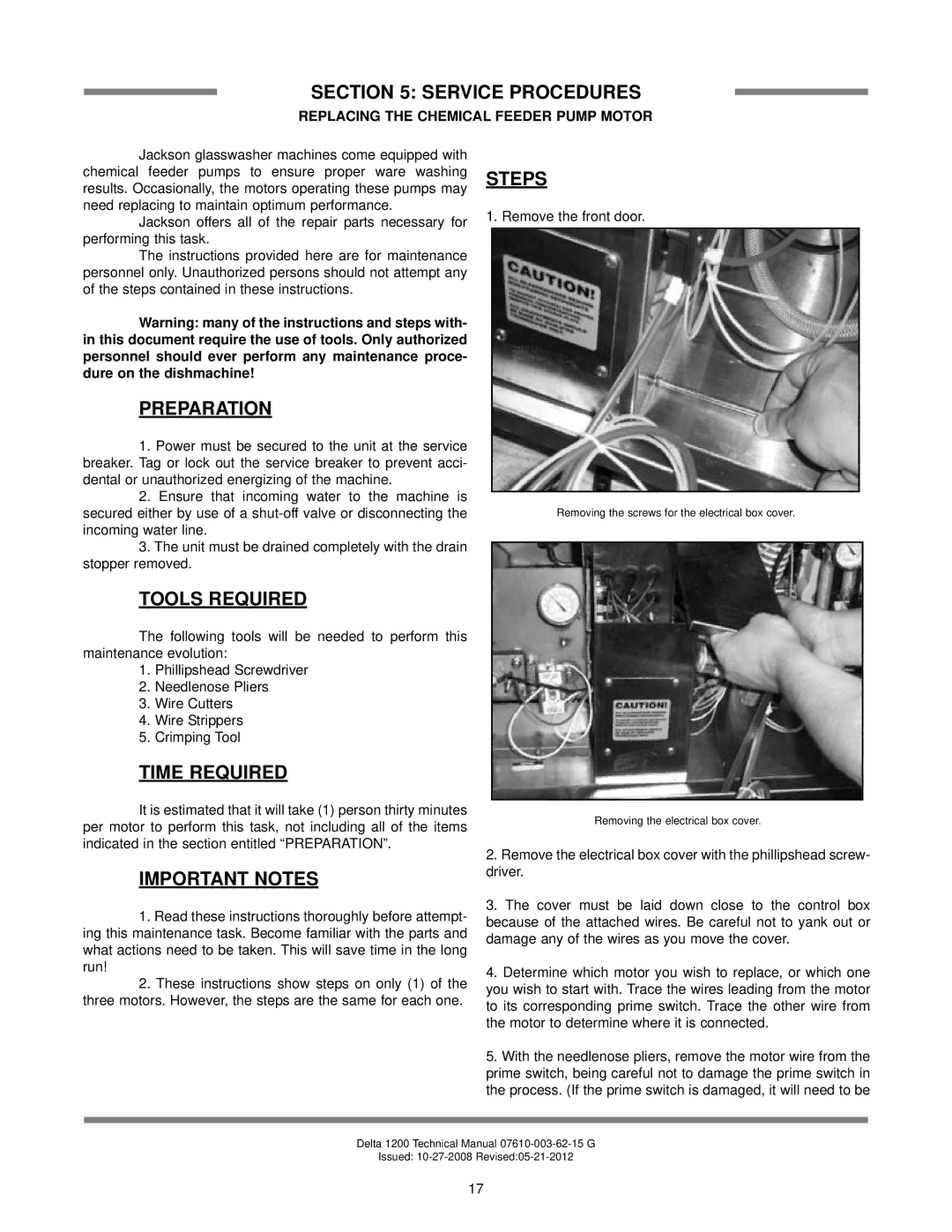

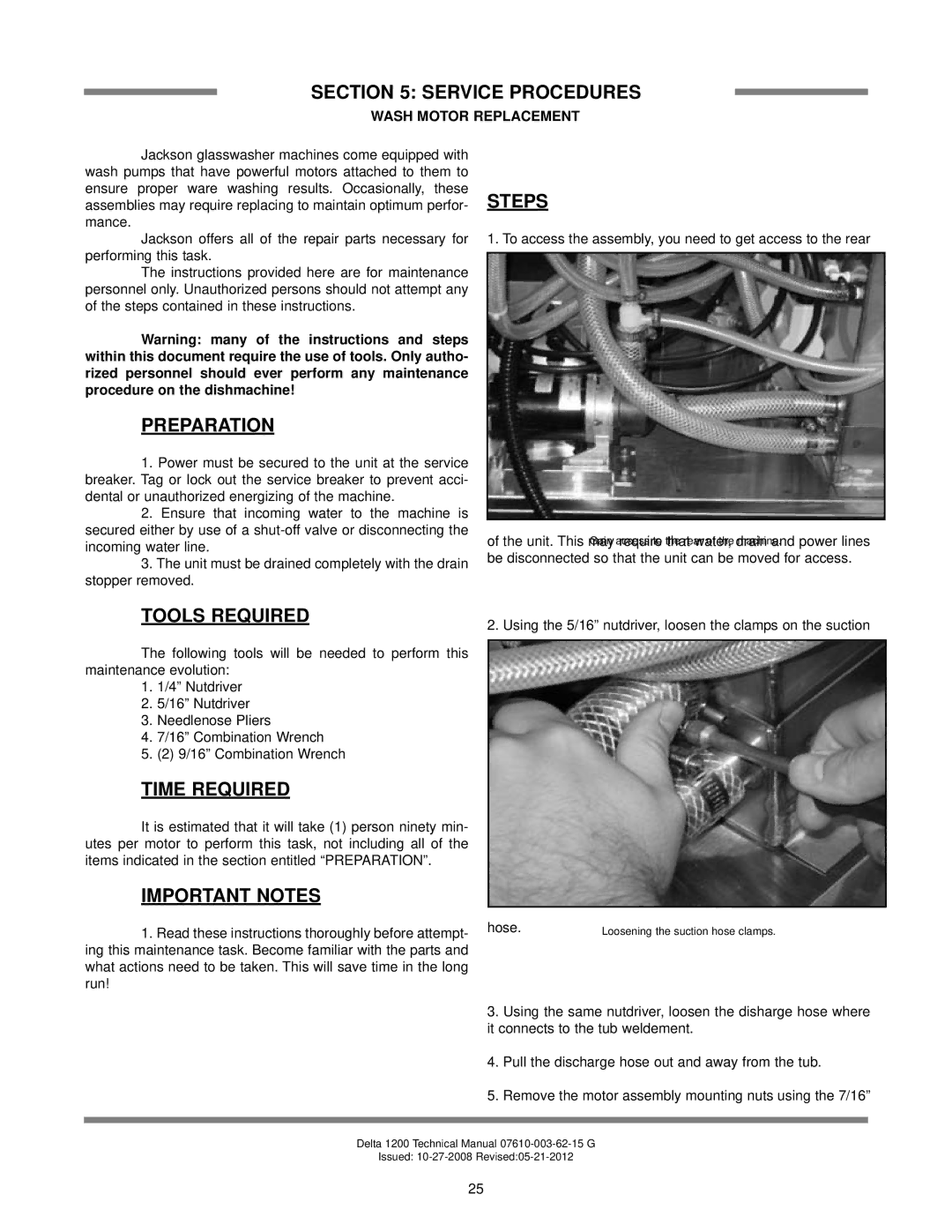

Removing the motor mounting screws.

AFTER MAINTENANCE ACTIONS

None.

SPECIAL NOTES

Work performed on Jackson dishmachines by unau- thorized or unqualified personnel may void the warranty. Before beginning this or any other maintenance evolution on a unit under warranty, you should contact a certified Jackson technician or Jackson Technical Service. You can find a list of qualified service agencies in the back of you unit’s installation manual.

SPECIAL PARTS

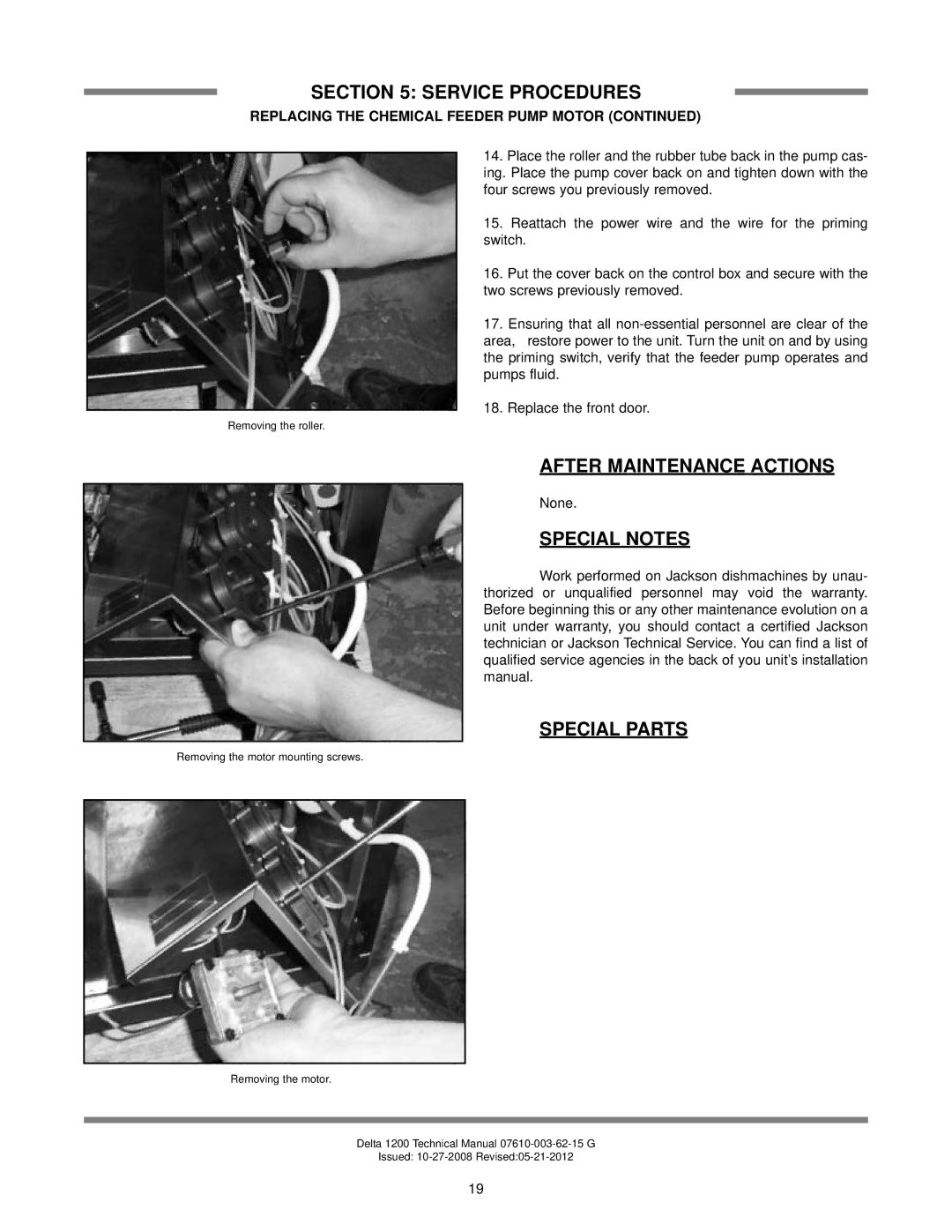

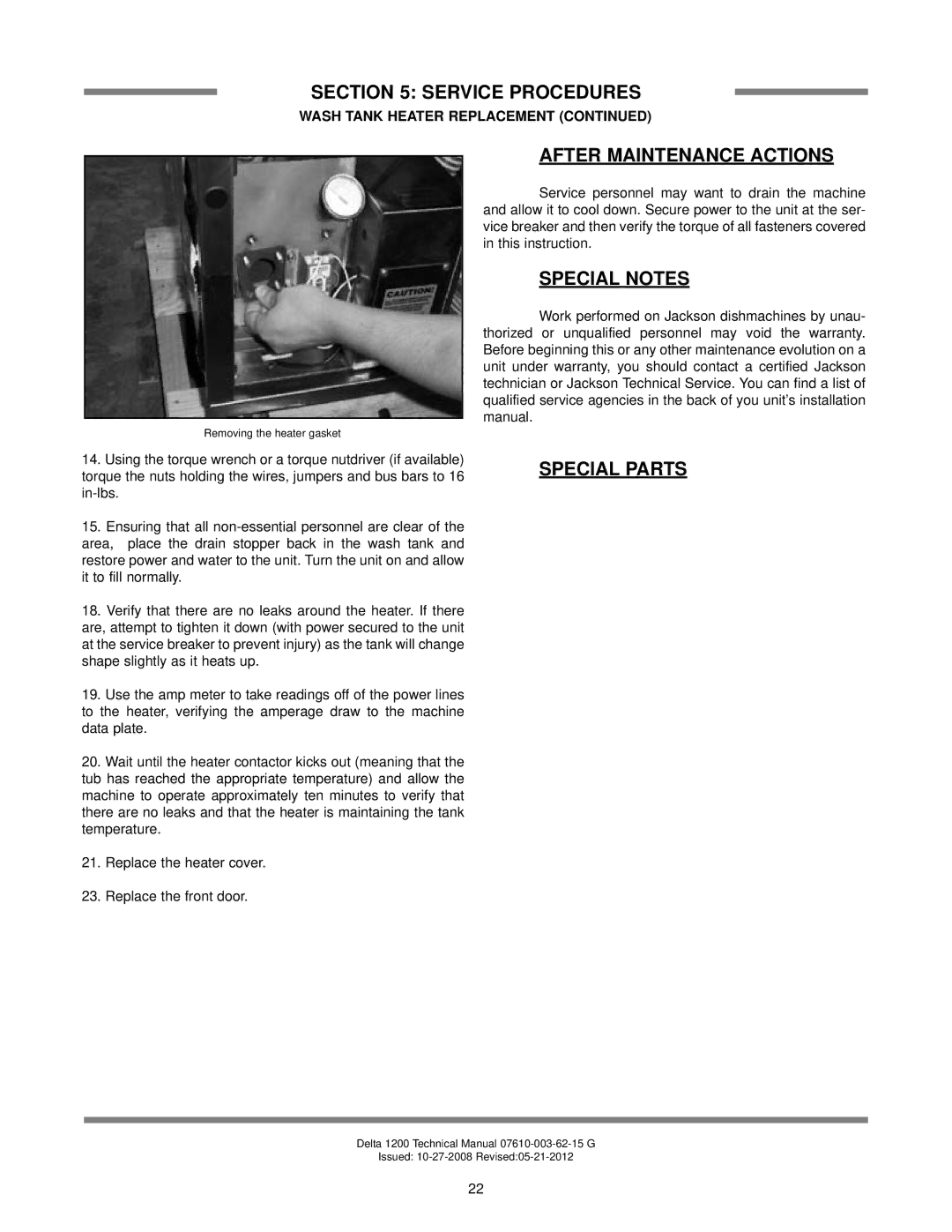

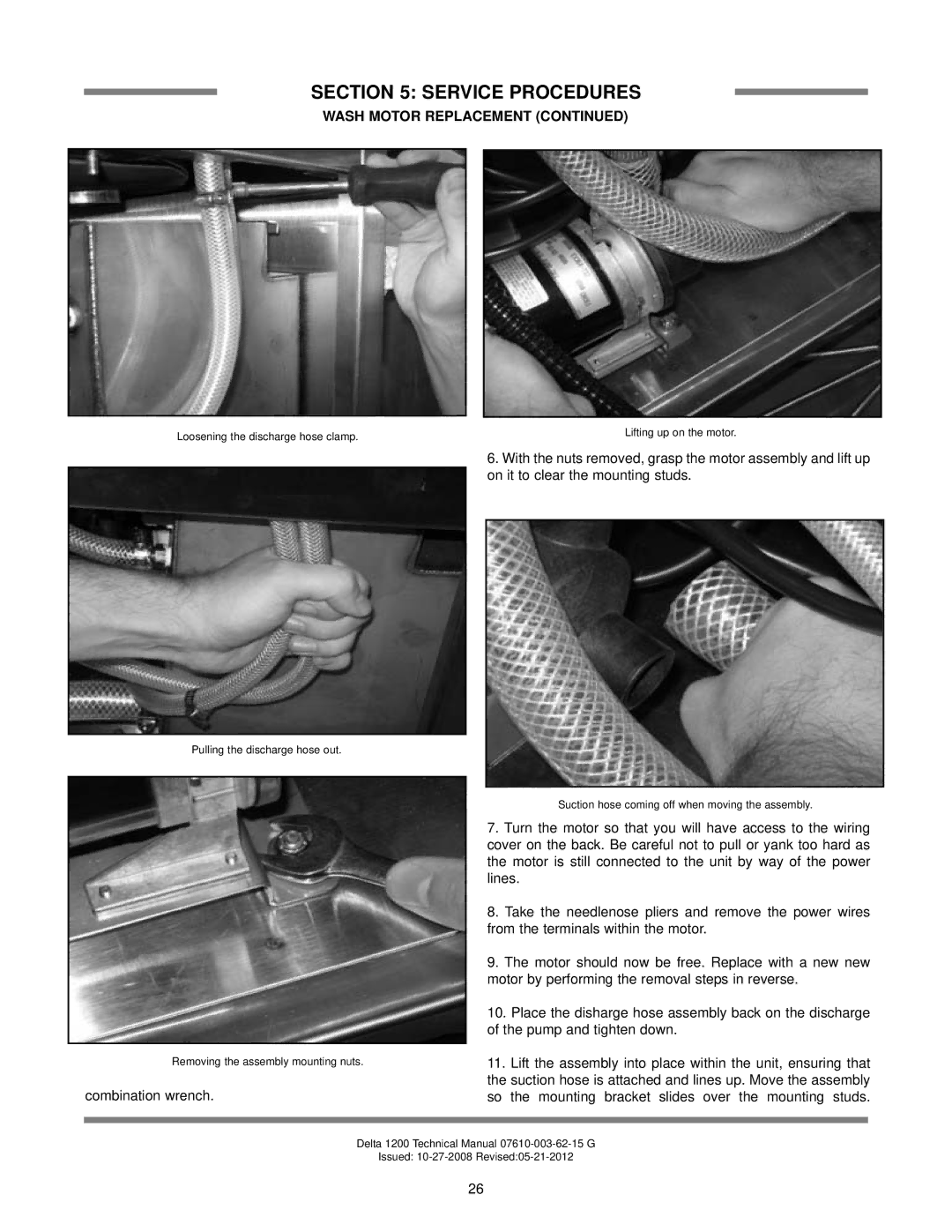

Removing the motor.

Delta 1200 Technical Manual

Issued:

19