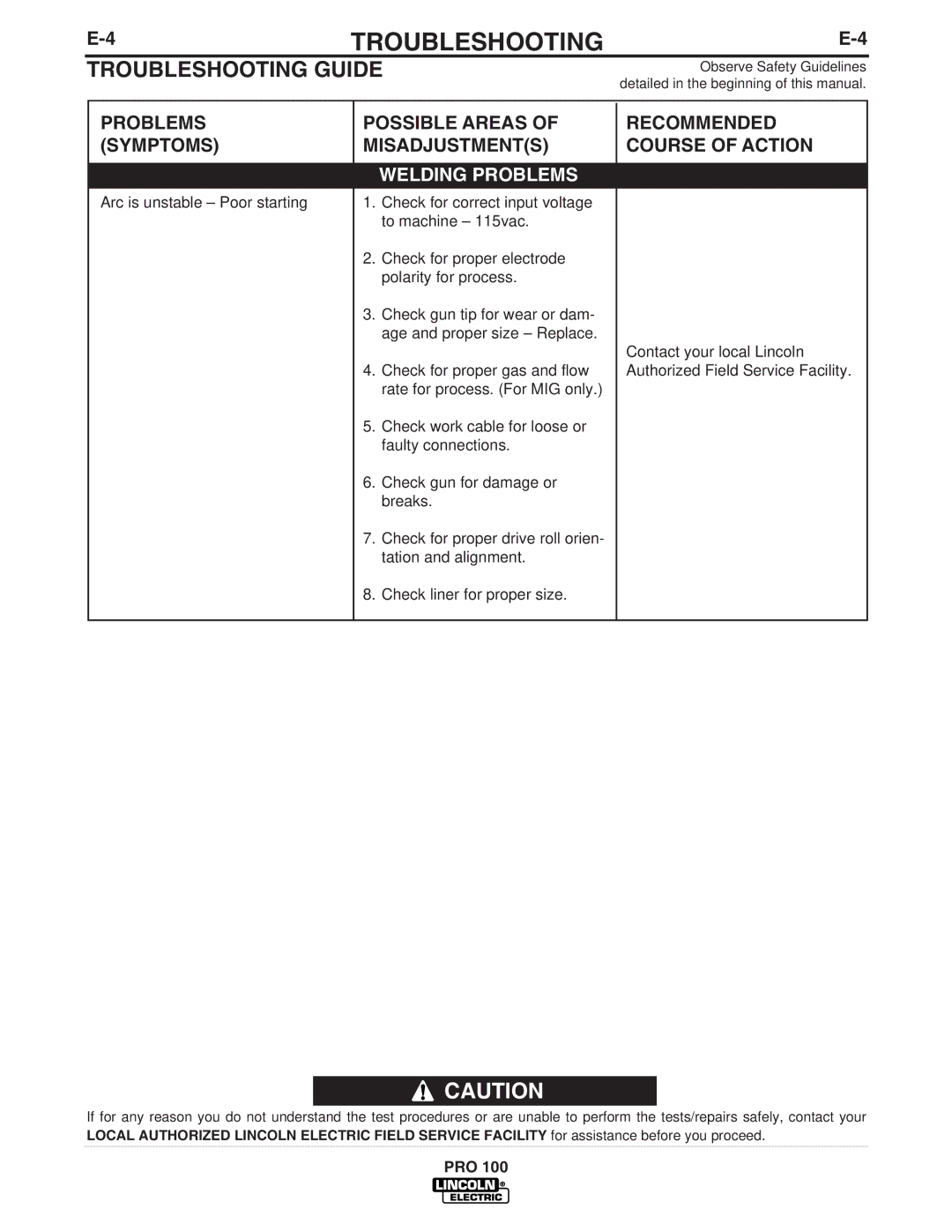

TROUBLESHOOTING | ||

|

|

|

TROUBLESHOOTING GUIDE

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS | POSSIBLE AREAS OF | |

(SYMPTOMS) | MISADJUSTMENT(S) | |

|

| OUTPUT PROBLEMS |

Major physical or electrical damage | None | |

is evident. | Contact your local Authorized Field | |

| Service Facility. | |

|

|

|

No wire feed, weld output or gas | 1. | Make sure correct voltage is |

flow when gun trigger is pulled. Fan |

| applied to the machine (115vac). |

does NOT operate. | 2. | Make certain that power switch |

| ||

|

| is in the ON position. |

| 3. | Make sure circuit breaker is |

|

| reset. |

|

|

|

No wire feed, weld output or gas | 1. | The thermostat may be tripped |

flow when gun trigger is pulled. Fan |

| due to overheating. Let machine |

operates normally. |

| cool. Weld at lower duty cycle. |

| 2. | Check for obstructions in air |

|

| flow. Check Gun Trigger connec- |

|

| tions. See Installation section. |

RECOMMENDED COURSE OF ACTION

Contact your local Lincoln Authorized Field Service Facility.

3. Gun trigger may be faulty.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

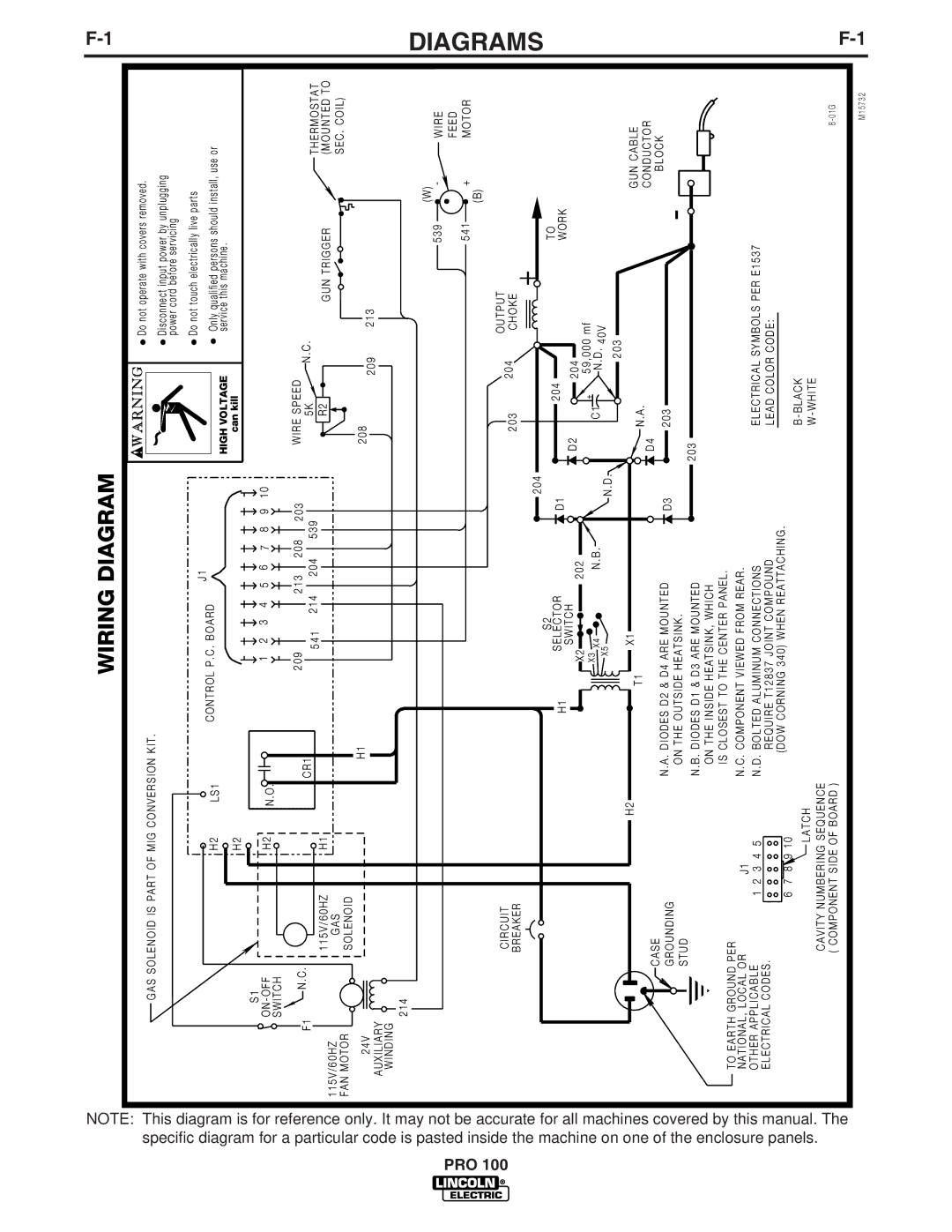

PRO 100