Easy Thread Cassette System

Cover a

Included Accessories

Accessories

Cover B

Names of Machine Parts and Their Functions

Front view

Cover C

Needle and presser foot section

Right-side/rear view

Operation buttons

Cover D

Operation panel

Cover E

Optional Accessories

Following are available as optional accessories

List of Embroidery Cards

Sewing Machine Features

Introduction

Contents

Stitch Settings

Adjusting the Thread Tension

Adjusting the Stitch Width and Length

Useful Functions

Sewing combined patterns

Maintenance

Sewing the Various Built-In Decorative Patterns

Designing a Pattern My Custom Stitch

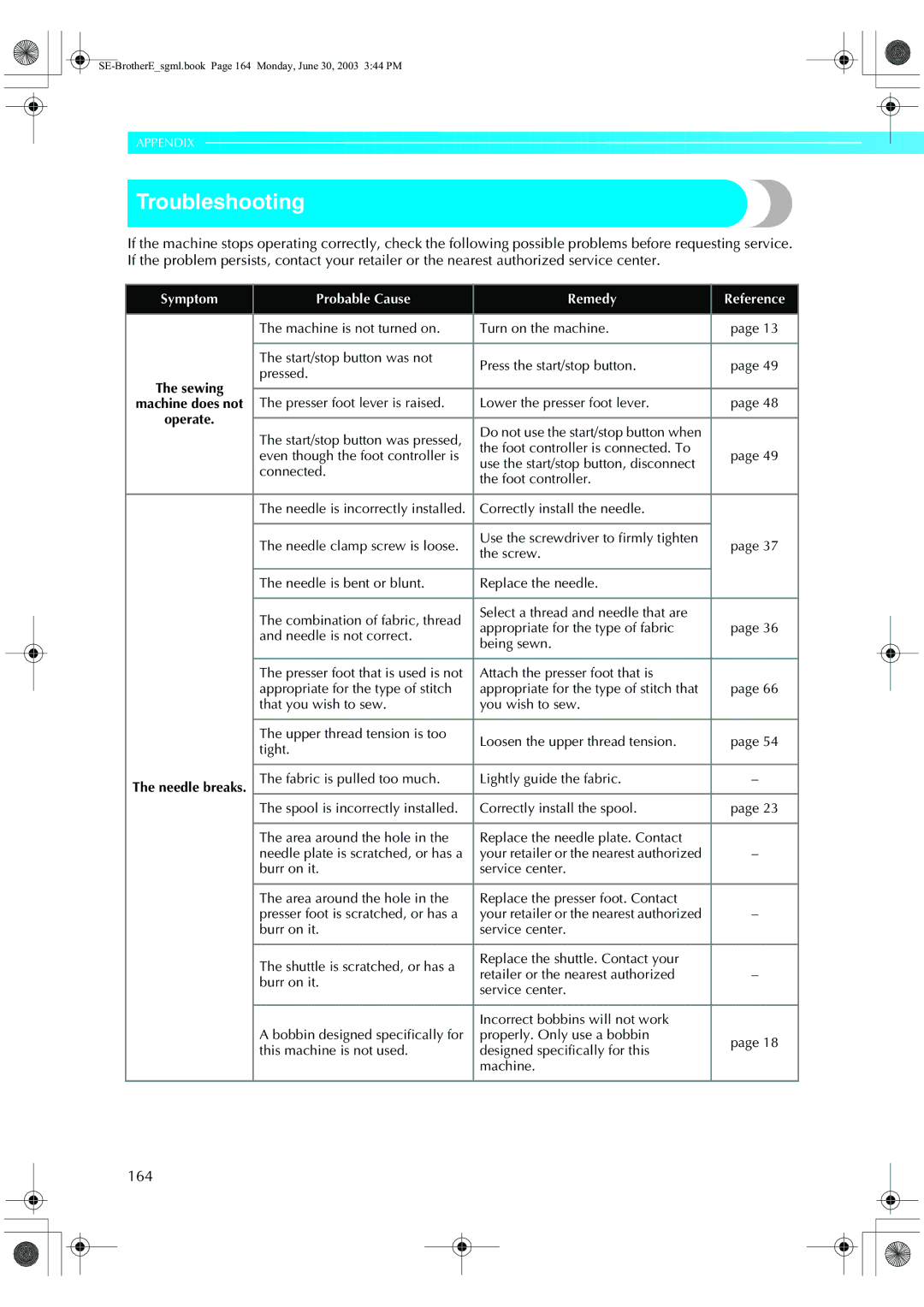

Troubleshooting

Index

Important Safety Instructions

For Users in the UK, EIRE, Malta and Cyprus only

BlueNeutral Brown Live

Congratulations on Choosing OUR Machine

Getting Ready

Power supply precautions

Turning the Machine On/Off

Turning the Machine On/Off

Turning on the machine

Turning off the machine

Utility stitch selection screen

LCD liquid crystal display operation

Viewing the LCD

Stitch group selection screen

Changing the Machine Settings

LCD liquid crystal display operation

DWhenkey. settings are complete, press Back

Settings screen appears

Switch screens using Previous page key Next page key

CPress the item to be set

Checking machine operating procedures

Winding the bobbin

Winding/Installing the Bobbin

Bobbin precautions

CSwing up the bobbin thread spool pin

Winding/Installing the Bobbin

Thread is cut to a suitable length

LPress Start/stop button once

ASlide the bobbin cover latch to the right

Installing the bobbin

Install the bobbin wound with thread

Bobbin cover opens

Cutter cuts the thread

Be careful not to drop the bobbin

Be sure to insert the bobbin correctly

GReattach the bobbin cover

Upper Threading

Upper Threading

About the spool of thread

Spools that can be loaded into the thread cassette

Loading the spool into the thread cassette

Thread cassette is raised

Follow arrow 5 indicated on the thread cassette

Close until it clicks

Follow arrow 2 indicated on the thread cassette

ACheck that the thread cassette indicator is lit up in green

Threading the needle

When embroidering, go to e

EClose the thread cassette compartment cover

Using the extra spool pin

Upper threading is finished

APlacepin. the spool of thread onto the extra spool

Refer to Replacing the needle

Extra spool pin is now installed

ARemove the needle

CReplace the needle

Using the twin needle

For details, refer to Replacing the needle

JTurnstitch.on the sewing machine and select a

FInstall the twin needle

KPresspanel. Settings key in the operation

Press

AInsert the bobbin into the shuttle

Pulling up the bobbin thread

MPress Back key

NStart sewing

SE-BrotherEsgml.book Page 34 Monday, June 30, 2003 344 PM

Replacing the Needle

Needle precautions

Replacing the Needle

This section provides information on sewing machine needles

Ball point needle gold colored

Needle types and their uses

Thread and needle number

Transparent nylon thread

Correct needle

Checking the needle

Replacing the needle

Incorrect needle

Install the twin needle in the same way

APlace the needle in the hole in the needle- changing tool

HLowerneedle.the needle-changing tool off

Needle is installed

Needle can be removed from the needle bar

Needle-changing tool can not be used for the twin needle

Replacing the presser foot

Presser foot precautions

Replacing the Presser Foot

Replacing the Presser Foot

Presser foot is attached

For details, refer to Replacing the presser foot

Removing the presser foot holder

ARemove the presser foot

Sewing Cylindrical Pieces

Sewing Cylindrical Pieces

Free-arm sewing

ASlide the flap off to the left

SE-BrotherEsgml.book Page 44 Monday, June 30, 2003 344 PM

Sewing Basics

General sewing procedure

Sewing

Attach the presser foot

Selecting stitching

Sewing

CTurn on the sewing machine

Fabric is now positioned to be sewn

Positioning the fabric

CPlace the fabric under the presser foot

Starting to sew

HCut the threads

For U.S.A. only Foot controller Model N5V

Machine stops sewing with the needle lowered in the fabric

Machine stops sewing

Securing the stitching

For details, refer to Starting to sew Machine starts sewing

Machine starts sewing in the normal sewing direction

Release the start/stop button or foot controller

When you have finished sewing, cut the threads

Cutting the thread

Sewing stitches

Using the thread cutter

Correct thread tension

Adjusting the Thread Tension

Thread tension

Upper thread is too tight

CTest it until the thread tension is suitable

Adjusting the Thread Tension

Changing the upper thread tension

BSelect a stitch

Adjusting the Stitch Width and Length

Adjusting the stitch width

Stitch length can be adjusted on the LCD

Adjusting the stitch length

Adjusting the Stitch Width and Length

SE-BrotherEsgml.book Page 58 Monday, June 30, 2003 344 PM

CPress on the LCD

Useful Functions

Useful Functions

Once

Automatically cutting the thread

EOnce you have reached the end

Mirroring stitches

DSet the fabric in place, and press Start/ stop button once

Thread is cut here

Changing the sewing direction

Useful Sewing Tips

Trial sewing

Sewing curves

Sewing stretch fabrics

Sewing thick fabrics

Sewing thin fabrics

Useful Sewing Tips

Aligning the fabric with the guide foot

Sewing an even seam

Allowance

Aligning the fabric with the presser foot

Utility Stitches

Stitch Settings

Utility stitches

Stitch Settings

Stitch Name

Stitch Settings

Quilting background stitching 7.0 4.0

Yes

Yes Pattern for making adjustment

Other stitches

BAttach the presser foot

Selecting Stitching

Stitch types

DPresspanel. Menu key on the operation

GPress the stitch selection

Selecting Stitching

FSelect the stitch type

AAttach overcasting foot G

Sewing overcasting stitches using overcasting foot G

Overcasting Stitches

AAttach zigzag foot J

Sewing overcasting stitches using zigzag foot J

Overcasting Stitches

Sewing overcasting stitches using the side cutter

ILowersewing.the presser foot lever, and then start

HPosition the fabric in the side cutter

If the fabric is not positioned correctly,

Basic stitching

Basic Stitching

Basting

Basic Stitching

FWhen sewing is finished, cut the thread

For details, refer to Adjusting the stitch width

EStart sewing

CAttach blind hem foot R

Blind Hem Stitching

Stitch

DSelect a stitch

Needle is too far to the left

Blind Hem Stitching

If the needle catches too much of the hem fold

Hem

Buttonhole Stitching

Buttonhole sewing

Buttonhole Stitching

CAttach buttonhole foot a

If the button does not fit in the button guide plate

Size of the buttonhole is set

FPullpossible.down the buttonhole lever as far as

Buttonhole lever b Bracket

Sewing buttonholes on stretch fabrics

Attach button-sewing foot M

Button sewing

Feed dogs are lowered

DSelect stitch

Do not press the thread cutter button

Zipper Insertion

Zipper Insertion

Inserting a centered zipper

Zipper can be sewn in place

ITopstitch around the zipper

JRemove the basting stitching

Inserting a side zipper

Wrong side of fabric b 3 mm 1/8 inch

SE-BrotherEsgml.book Page 92 Monday, June 30, 2003 344 PM

NTopstitch around the zipper

Elastic attaching

Sewing Stretch Fabrics and Elastic Tape

Stretch stitching

CSew the fabric without stretching it

Sewing Stretch Fabrics and Elastic Tape

Quilting

Appliqué, Patchwork and Quilt Stitching

Appliqué stitching

Appliqué, Patchwork and Quilt Stitching

DAttach zigzag foot J

Piecing

Edge of the fabric, and sew using stitch

Patchwork crazy quilt stitching

Select stitch 57 or

BRemove the presser foot holder

Quilting

For a seam allowance on the left side

For details, refer to Removing the presser foot holder

100

Turnstitch.on the sewing machine, and then select a

Free-motion quilting

Refer to Removing the presser foot holder

Normally, the drop feed lever is positioned at the right

AConnect the foot controller

Satin stitching

102

EPress Back key

Bar tack stitching

Reinforcement Stitching

Triple stretch stitching

Reinforcement Stitching

Mm 1/16 inch in front of the pocket opening

104

BAttach buttonhole foot a

EPullpossible.down the buttonhole lever as far as

Darning

CSelect stitch 52 or

106

Eyelet stitch

Eyelet Stitching

Eyelet Stitching

AAttach monogramming foot N

Decorative Stitching

108

CAttach zigzag foot J Select stitch 26 or

Fagoting

Decorative Stitching

Set the stitch width to 7.0 mm 1/4 inch

110

Scallop stitching

Smocking

FStitch between the straight stitches

Shell tuck stitching

Select stitch 25 , 26 or

CSelecttension.stitch 20 , and then increase the thread

Select stitch 22 , 23 or

Joining

112

BAttach monogramming foot N

AInstall the wing needle

Heirloom stitching

DStart sewing

114

Pattern is flipped

DSew along the center of the unfrayed section

Sewing patterns

Sewing the Various Built-In Decorative Patterns

Sewing beautiful patterns

116

Sewing the Various Built-In Decorative Patterns

Changing satin stitch length

Realigning the pattern

Select

118

Sewing combined patterns

Sewing combined patterns

Combining patterns

BSelect the first pattern

120

Storing a pattern

Deleting a stored pattern

DCheck the contents if they can be deleted, then Press

122

ASelect one of the stitch groups except

Designing a Pattern My Custom Stitch

Designing a Pattern My Custom Stitch

Drawing a sketch of the pattern

Prepare a grid sheet set

BPress Menu key on the operation Panel, and then press

Entering the pattern data

124

HAfter all points have been entered, press

To revise the pattern, press

Point

Examples of designs

126

Embroidery

Steps for embroidering will be explained here

128

Embroidering neatly

What to prepare

Embroidering neatly

Needle

Embroidery step by step

130

Attaching the embroidery foot

Attaching the embroidery foot

Attaching the embroidery foot

BTurn off the sewing machine

Remove the presser foot holder

132

Turn the screwdriver toward the back

Set the embroidery foot perpendicular

EAttach the presser foot holder

Removing the embroidery foot

BTurn off the sewing machine CRaise the presser foot lever

For details, refer to Attaching the presser foot holder

Attaching the embroidery unit

Embroidery unit precautions

Attaching the embroidery unit

134

ESlide the embroidery unit onto the sewing machine arm

Attaching the embroidery unit

DRemove the embroidery unit cover

FTurn on the sewing machine

BRemove the embroidery frame

Removing the embroidery unit

136

Embroidery unit separates from the sewing machine

Attaching a stabilizer material to the fabric

† When it cannot be ironed or placed in the hoop

Preparing the fabric

138

Setting the fabric in the embroidery frame

Preparing the fabric

140

We recommend stabilizer material for embroidery

BPlace the embroidery sheet on the inner frame

For details, refer to

142

Attaching the embroidery frame

Attaching the embroidery frame

BRaise the presser foot lever

Remove the embroidery frame

Removing the embroidery frame

Attaching the embroidery frame

Embroidery pattern types

Selecting embroidery patterns

Copyright Information

144

Operation keys

LCD liquid crystal display operation

Selecting embroidery patterns

LCD button

† Example Welcome

Selecting characters

146

Pattern selection screen is displayed

Selecting embroidery patterns

APress embroidery pattern

BSelect the pattern

APress the frame pattern

Selecting a frame pattern

148

BSelect the frame shape

Using an embroidery card

ESelect a pattern

150

Embroidering

Embroidering a pattern

Embroidering

Applique Position will be displayed on the LCD

Appliquéing

152

Applique will be displayed on the LCD

SE-BrotherEsgml.book Page 153 Monday, June 30, 2003 344 PM

Convenient Functions

Adjusting the layout

CCheck and adjust the layout

154

BSelect5. the pocket for storage from pockets

Storing characters

Convenient Functions

CPress

APress Memory key

CAfter checking the content, press

156

Resewing

Adjusting the thread tension

DSet up the correct color for the upper thread

Tight Loose

158

Thread runs out partway through a design

Stopping while embroidering

DRestart the embroidery

ETurn off the sewing machine

160

Appendix

Cleaning the shuttle

Maintenance

Cleaning the machine surface

162

Grasp the shuttle, and then pull it out

Maintenance

DRemove the shuttle

Do not apply oil to the shuttle

164

Troubleshooting

Correctly install the needle

Presser foot lever is raised Lower the presser foot lever

Remove the tangle thread. If

Troubleshooting

Upper thread was not Threaded correctly for example

Shuttle

166

Is tangled or

Skipped

168

LCD

Error messages

Error Message Probable Cause

170

SE-BrotherEsgml.book Page 171 Monday, June 30, 2003 344 PM

172

Nothing appears in the LCD

Operation beep

Screen for changing the beep setting appears

Cancelling the operation beep

Press Settings key in the operation Bpanel

CPress Next page key. dPress OFF for the buzzer

Index

174

Index

176

66, 78

English 885-S15/S14 XC6369-1211

![]() APPENDIX

APPENDIX ![]() ——————————

——————————![]() ———————————

———————————