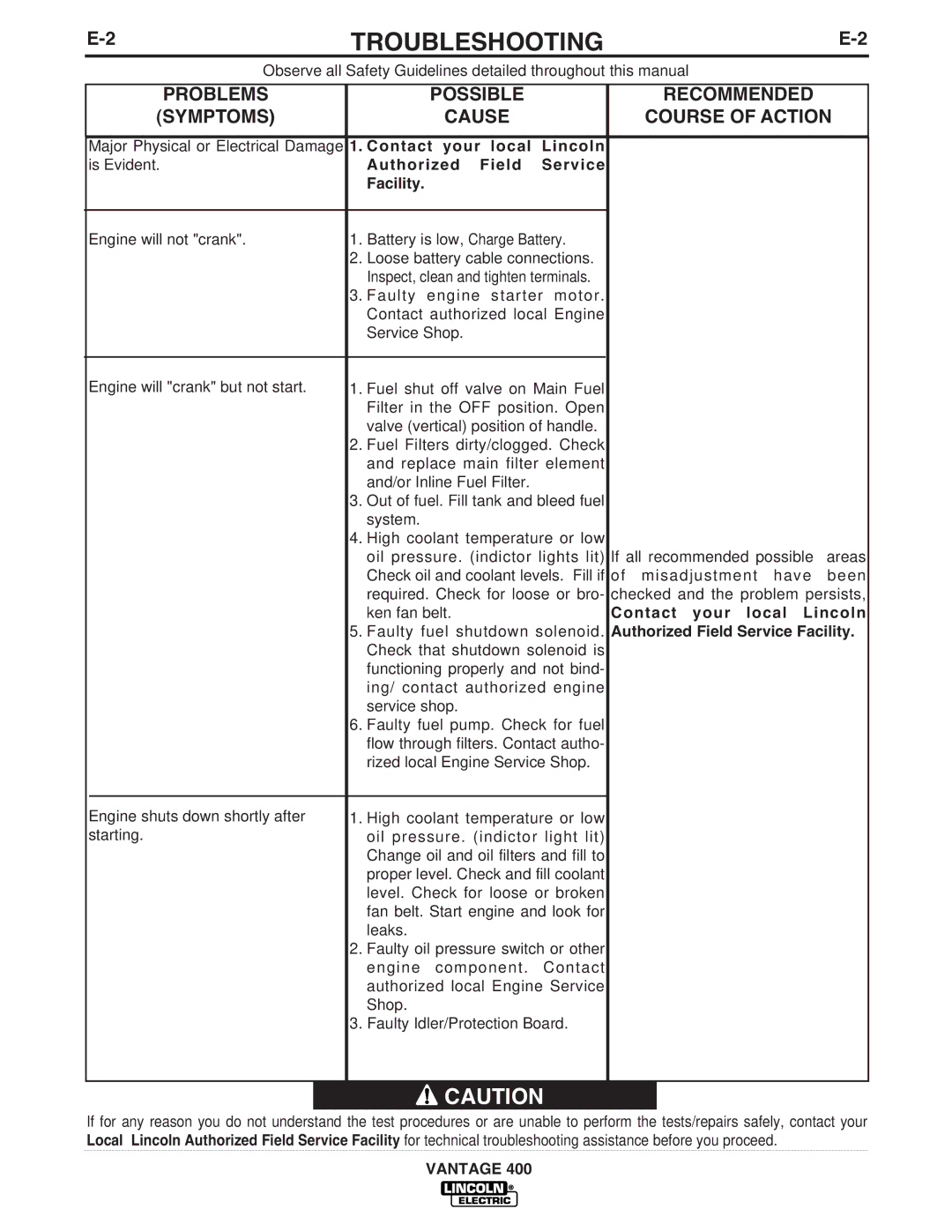

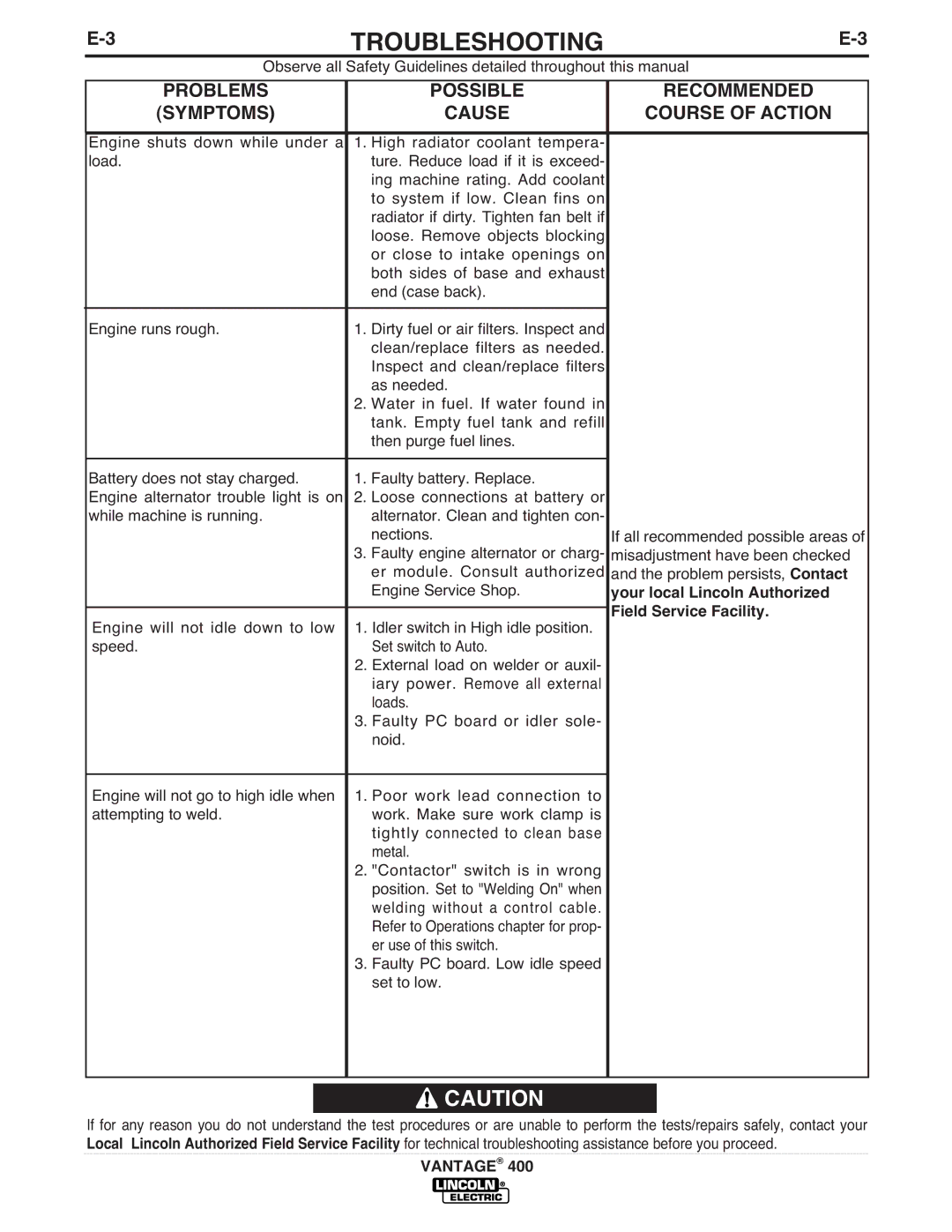

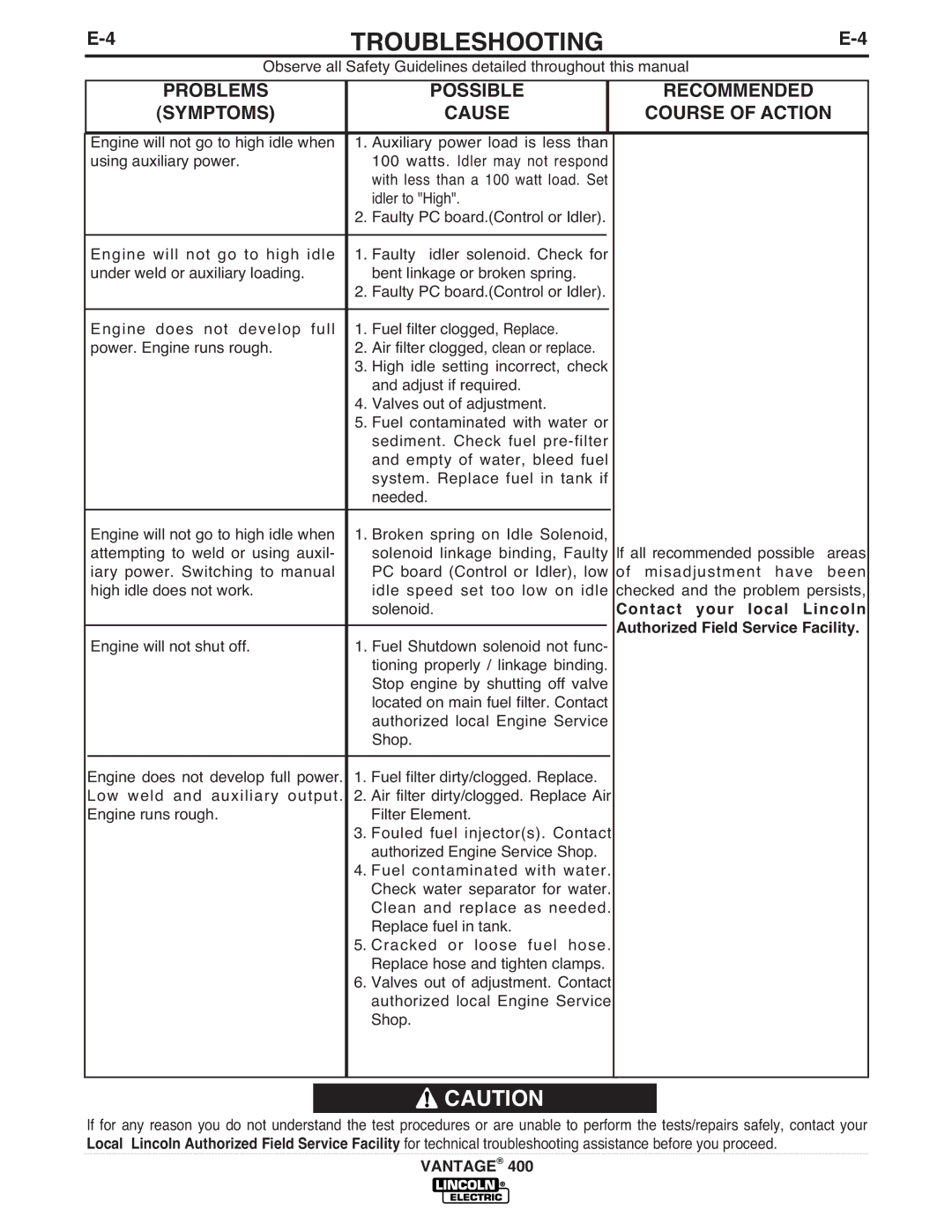

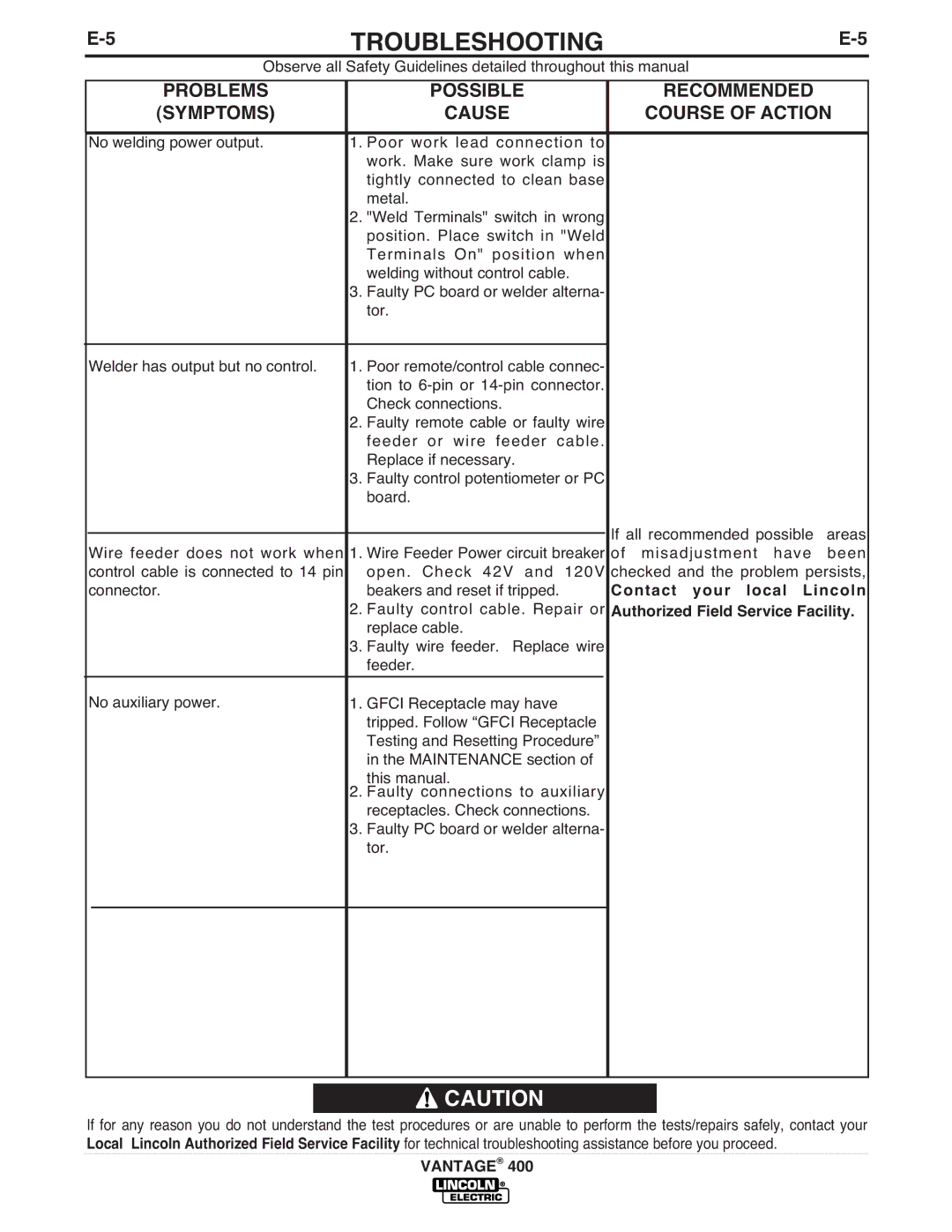

TROUBLESHOOTING | ||

|

|

|

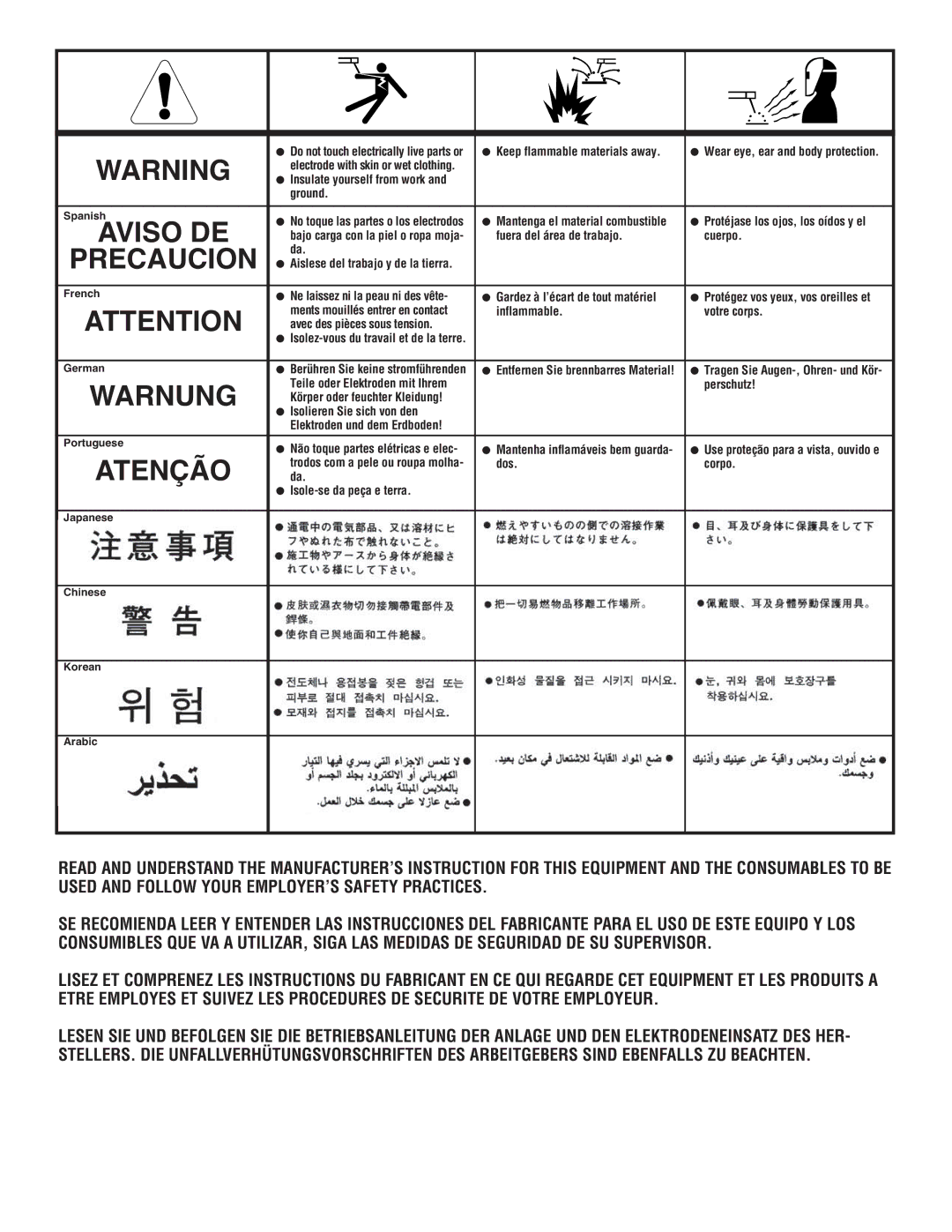

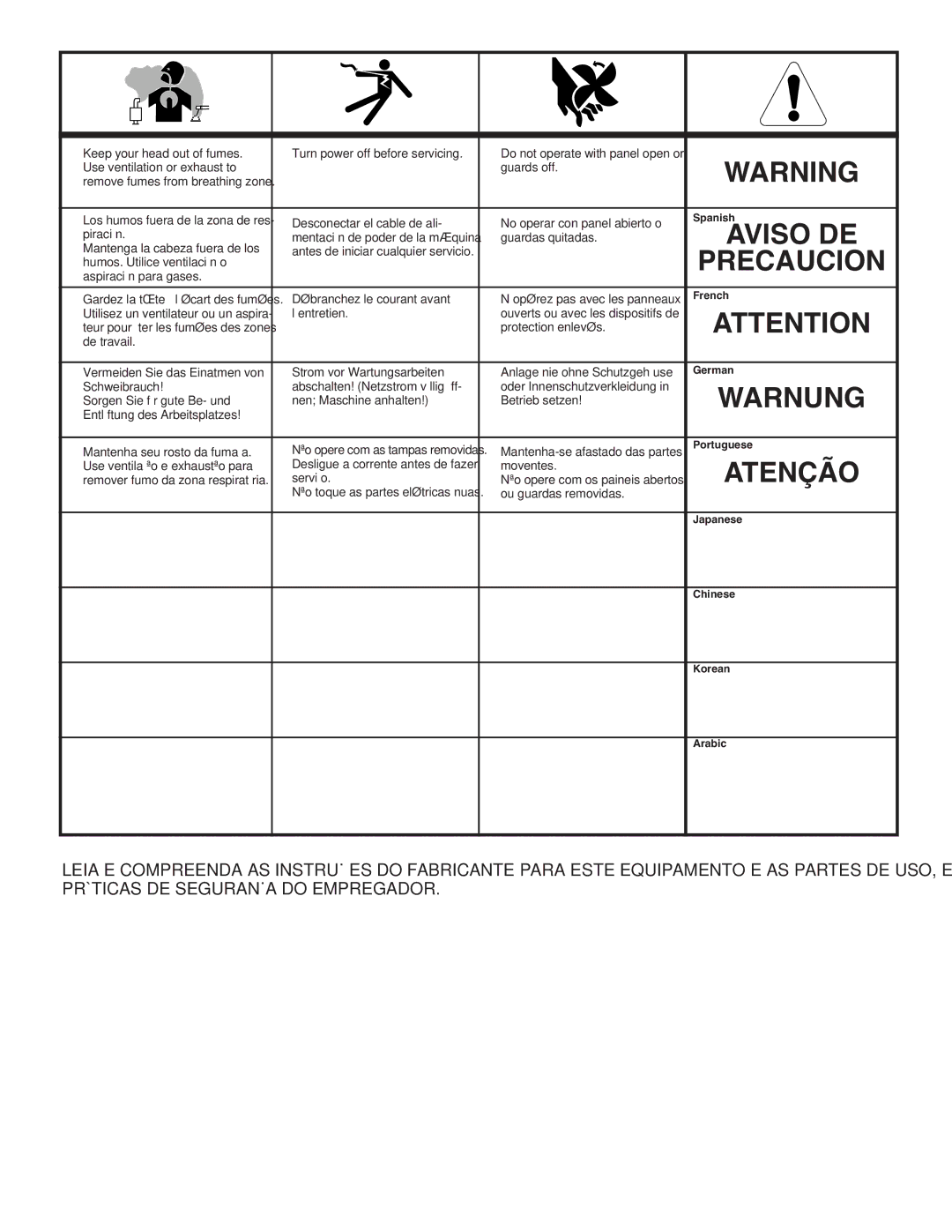

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

|

|

| If all recommended possible areas of | |

|

|

| misadjustment have been checked | |

|

|

| and the problem persists, Contact | |

|

|

| your local Lincoln Authorized | |

No output in Pipe Mode. | 1. Make sure VRD ON/OFF toggle | |||

Field Service Facility. | ||||

|

| switch is in the “OFF” position. |

| |

| 2. Poor work lead connection to |

| ||

|

| work. Make sure work clamp is |

| |

|

| tightly connected to clean base |

| |

|

| metal. |

| |

| 3. | "Weld Terminals" switch in wrong |

| |

|

| position. Place switch in "Weld |

| |

|

| Terminals On" position when |

| |

|

| welding without control cable. |

| |

| 4. | Faulty PC board or welder alterna- |

| |

|

| tor. |

| |

|

|

|

| |

VRD Lights donʼt light up. | 1. | Ensure VRD ON/OFF switch is in |

| |

|

| the “ON” position. |

| |

| 2. | If light is burned out, replace both |

| |

|

| VRD lights. |

| |

| 3. Faulty OCV indicator PC board. |

| ||

|

|

|

| |

|

|

|

| |

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

VANTAGE® 400