INSTALLATION |

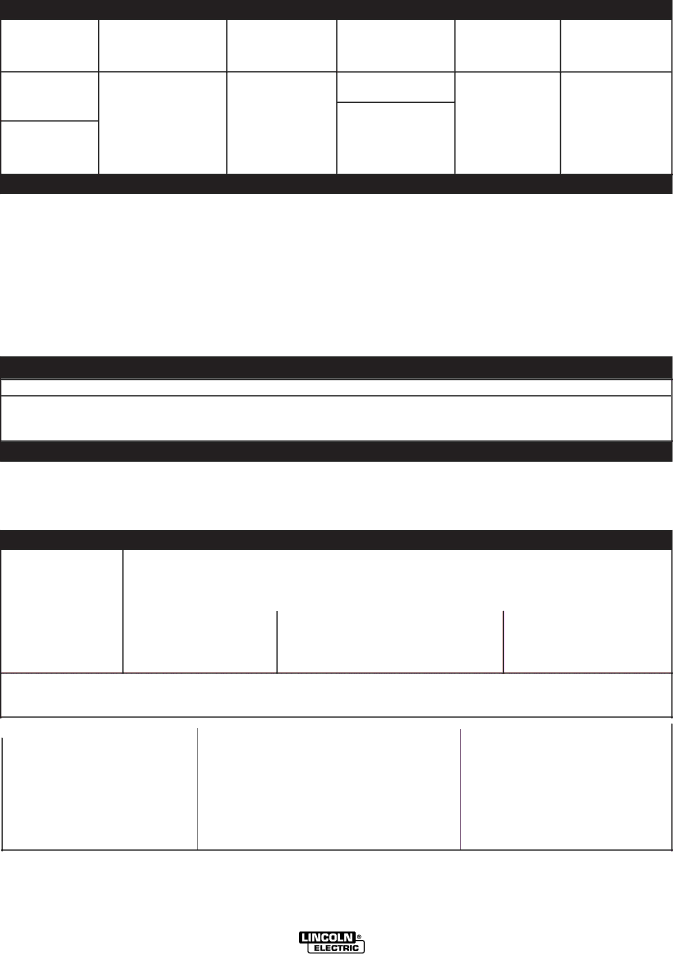

TECHNICAL SPECIFICATIONS - VANTAGE 400 (K2410-1) (K2410-2)

INPUT - DIESEL ENGINE

Make/Model

PERKINS

Description

4cylinder 32.7 HP

1800 RPM naturally aspirated water cooled Diesel Engine

Speed (RPM)

High Idle 1880

Full Load 1800

Low Idle 1400

Displacement cu. in. (ltrs.)

135.6(2.2)

Bore x Stroke inch (mm)

3.43 X 3.64

(87.1 x 92.5mm)

Starting

System

12VDC Battery & starter

(Group 34; 650 cold crank amps)

65 Amp Alternator

W / Built in Regulator

Capacities

Fuel: 15 gal. (57 L)

Oil: 8.45Qts. (8L)

Radiator Coolant: 8.0 Qts. (7.6L)

RATED OUTPUT @ 104° F (40° C) - WELDER

Welding Process | Welding Output | Output Range | Max. Weld OCV | |

| Current/Voltage/Duty Cycle |

| @Rated Load RPM | |

| 400A / 36V / 100% |

|

| |

DC Constant Current | 450A / 32V / 100% | 30 TO 500 AMPS |

| |

|

|

|

| |

DC Pipe Current | 300A / 32V / 100% | 40 TO 300 AMPS | 2 | |

|

|

| 60 Volts | |

250A / 30V / 100% | 20 TO 250 AMPS | |||

| ||||

| 400A / 36V / 100% |

|

| |

DC Constant Voltage | 450A / 32V / 100% | 14 TO 36 VOLTS |

| |

|

|

|

|

RATED OUTPUT @ 104° F (40° C).- GENERATOR

Auxiliary Power 1

12,000 Watts Peak, / 11,000 Watts Continuous, 60 Hz 120/240 Volts Single Phase

19,000 Watts Peak, / 17,000 Watts Continuous, 60 Hz, 240 Volts

PHYSICAL DIMENSIONS

HEIGHT | WIDTH | DEPTH |

| WEIGHT | |

35.94* in. | 25.30 in | 60.00 in. |

|

|

|

| 1230 lbs. (559kg.) |

| |||

913 mm | 643 mm | 1524 mm |

|

| |

|

|

| |||

|

|

| |||

|

|

|

|

|

|

ENGINE

LUBRICATION | EMISSIONS |

|

| FUEL SYSTEM | GOVERNOR |

Full Pressure | Tier II | Mechanical Fuel Pump, Auto air bleed system | Mechanical | ||

with Full Flow Filter | Tier 4 interim |

| Electric shutoff solenoid, Indirect fuel injector. |

| |

| Compliant |

|

|

|

|

AIR CLEANER | ENGINE IDLER | MUFFLER | ENGINE PROTECTION |

|

| Low noise Muffler: | Shutdown on low oil |

Single Element | Automatic Idler | Top outlet can be rotated. | pressure & high engine |

|

| Made from long life, aluminized steel. | coolant temperature |

ENGINE WARRANTY: 2 years / 2000 hours, all

| MACHINE SPECIFICATIONS |

|

RECEPTACLES | AUXILIARY POWER CIRCUIT BREAKER | OTHER CIRCUIT BREAKERS |

|

|

|

(2) 120VAC GFCI Duplex | Two 20AMP for Two Duplex Receptacle | 10AMP for Battery Charging Circuit |

(1) 120/240VAC Dual Voltage | (1) 50AMP for Dual Voltage and for | 10AMP for 42V Wire Feeder Power |

Full KVA |

|

|

(1) 240VAC 3-Phase (15-50R)

1.Output rating in watts is equivalent to

*To Top of enclosure, add 10.68”(271.3mm) to top of exhaust pipe. Add 6.67”(169.4mm) to top of Lift Bail.

2. Reduced to less than 32V in the

VANTAGE® 400