ADJUSTMENTS

Belt Tracking

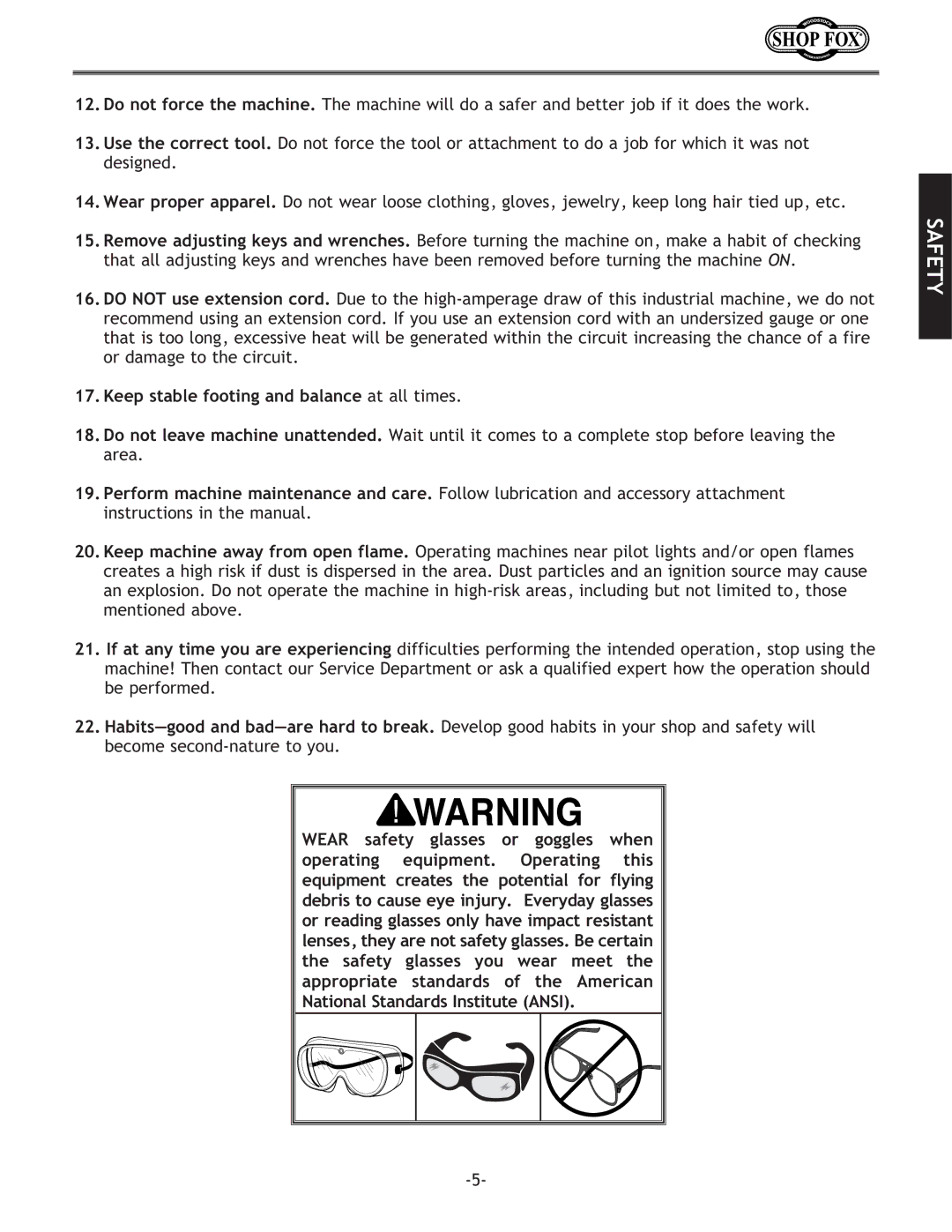

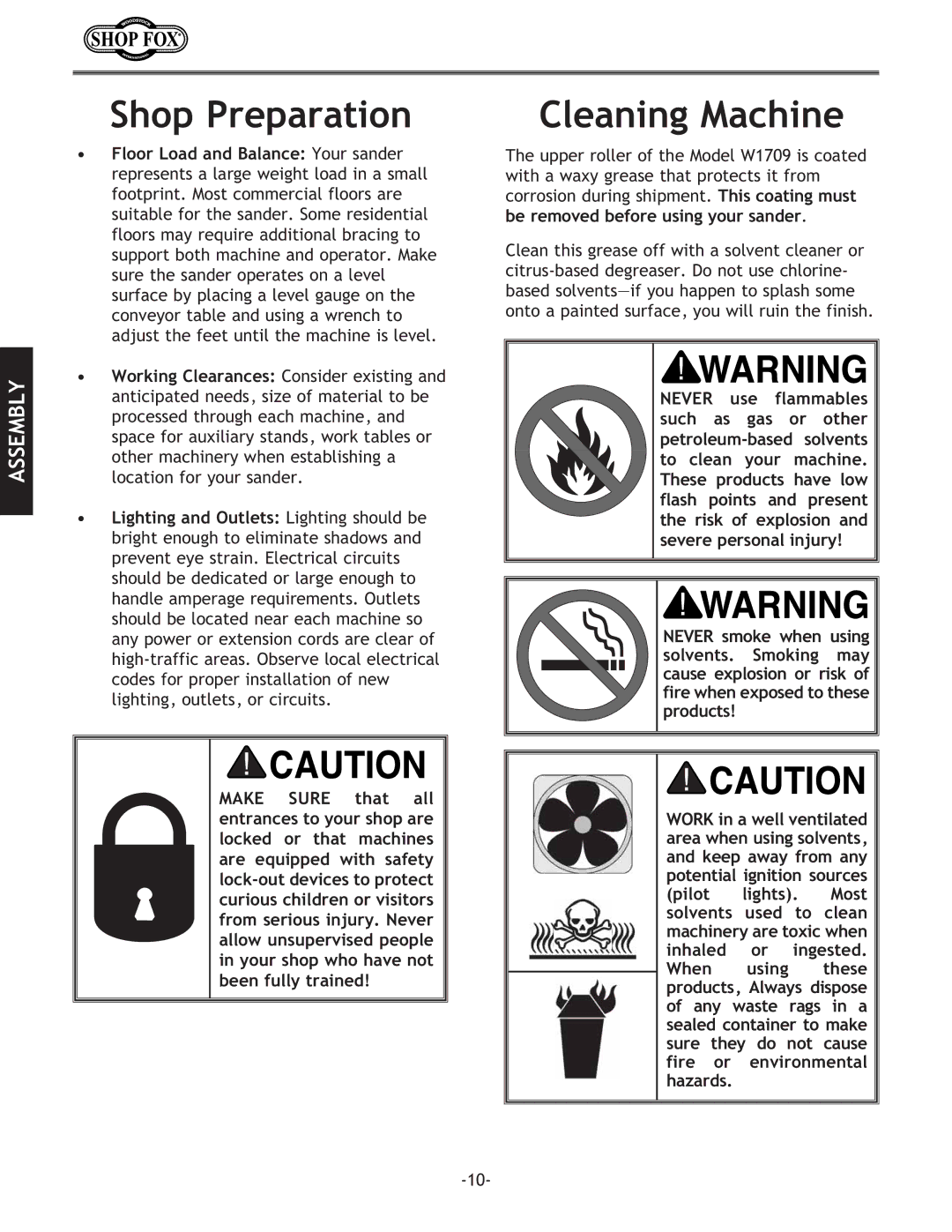

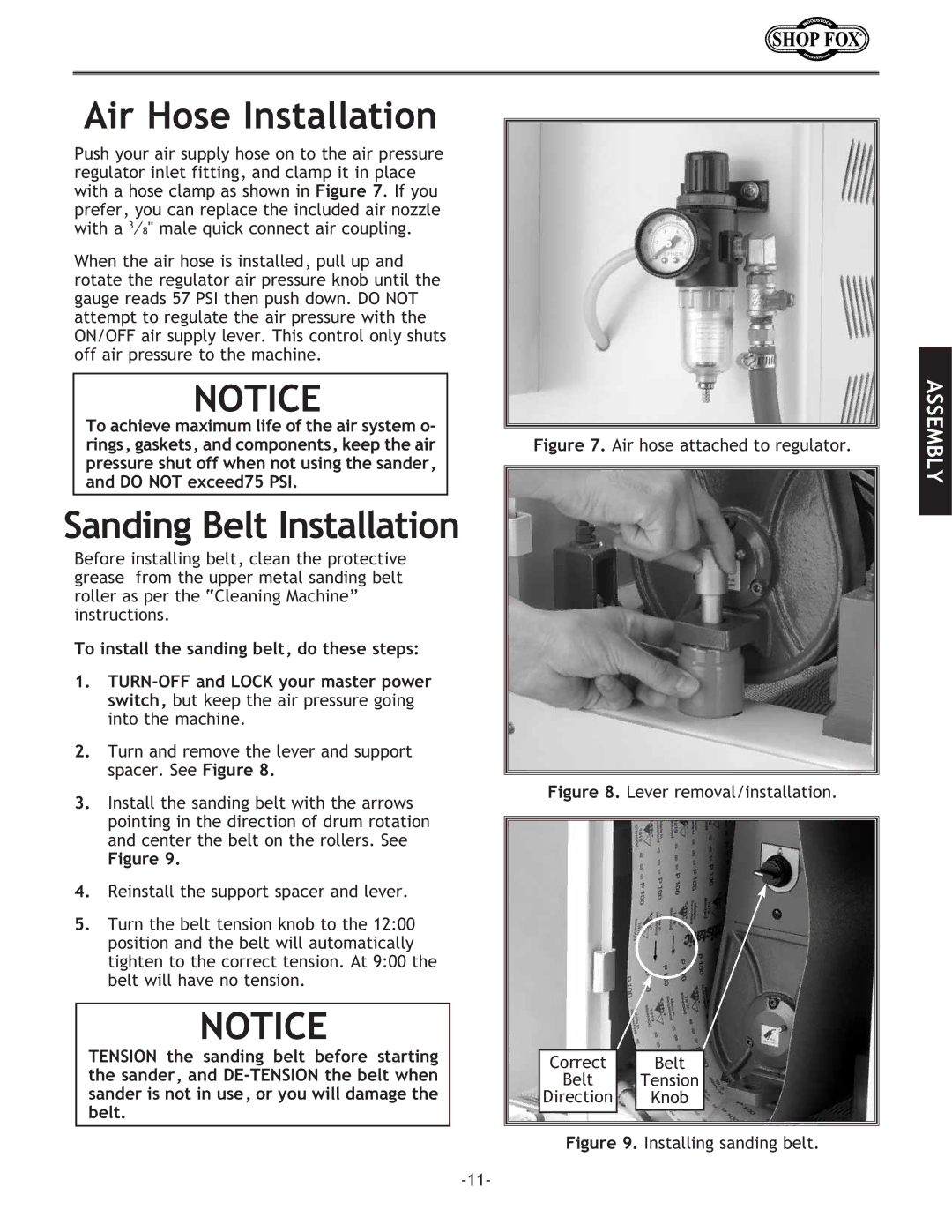

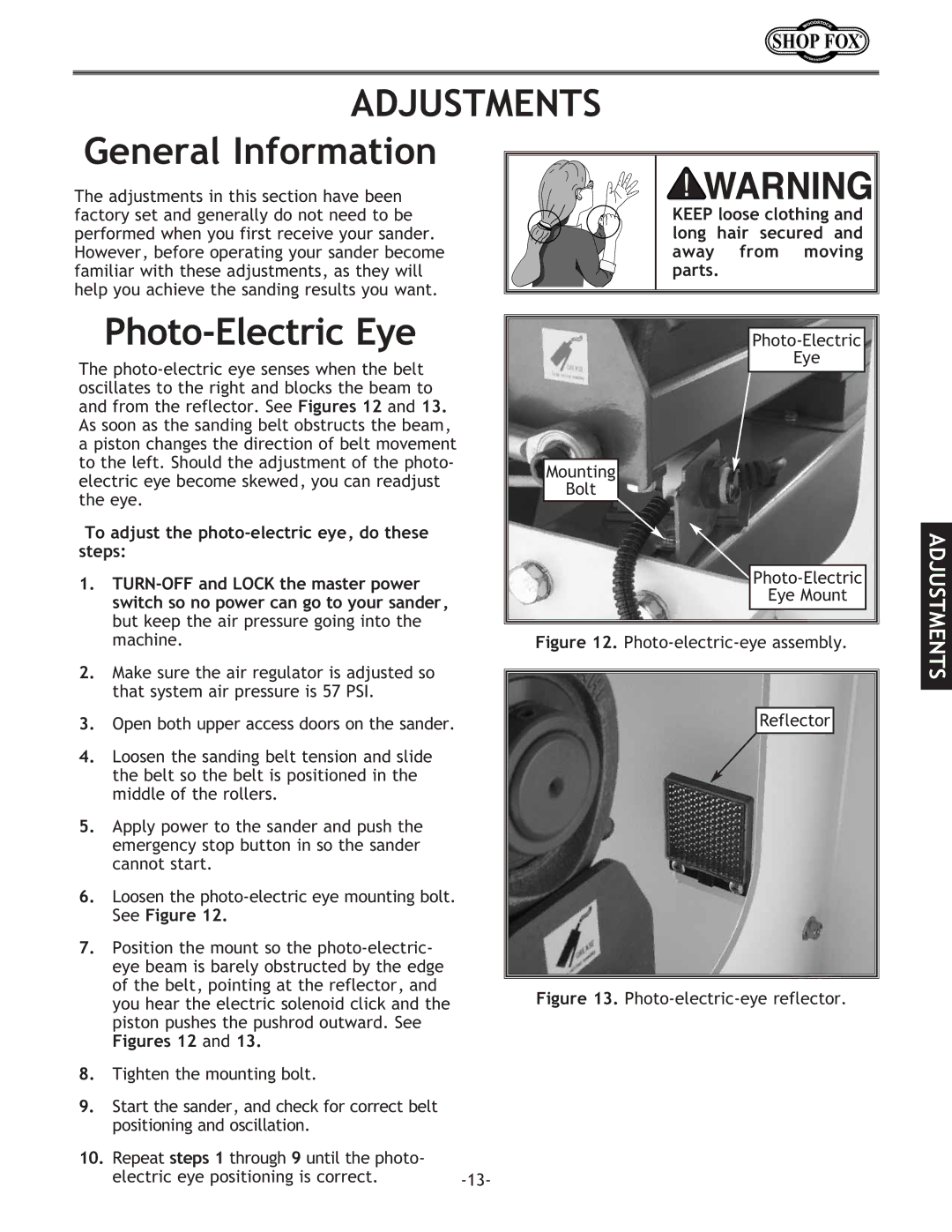

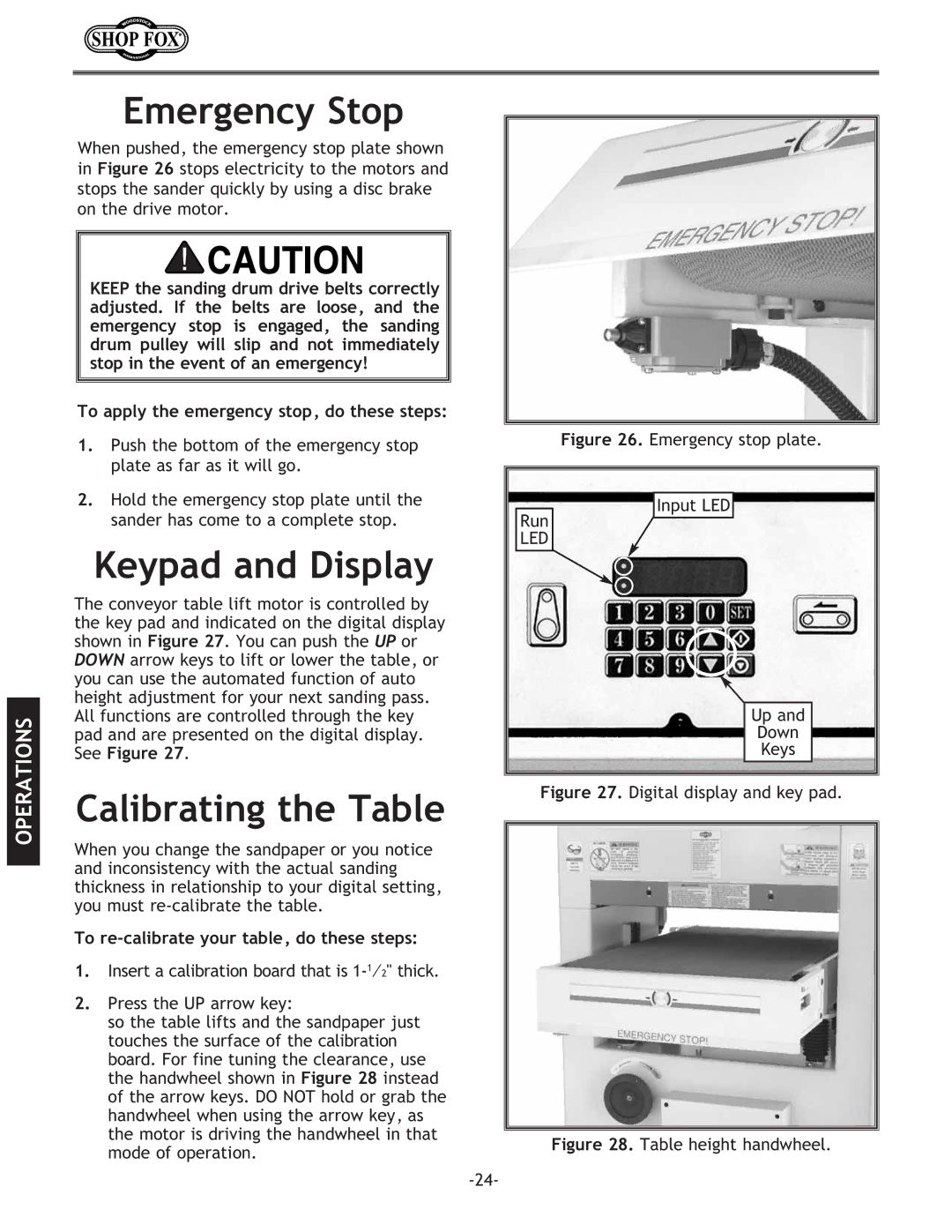

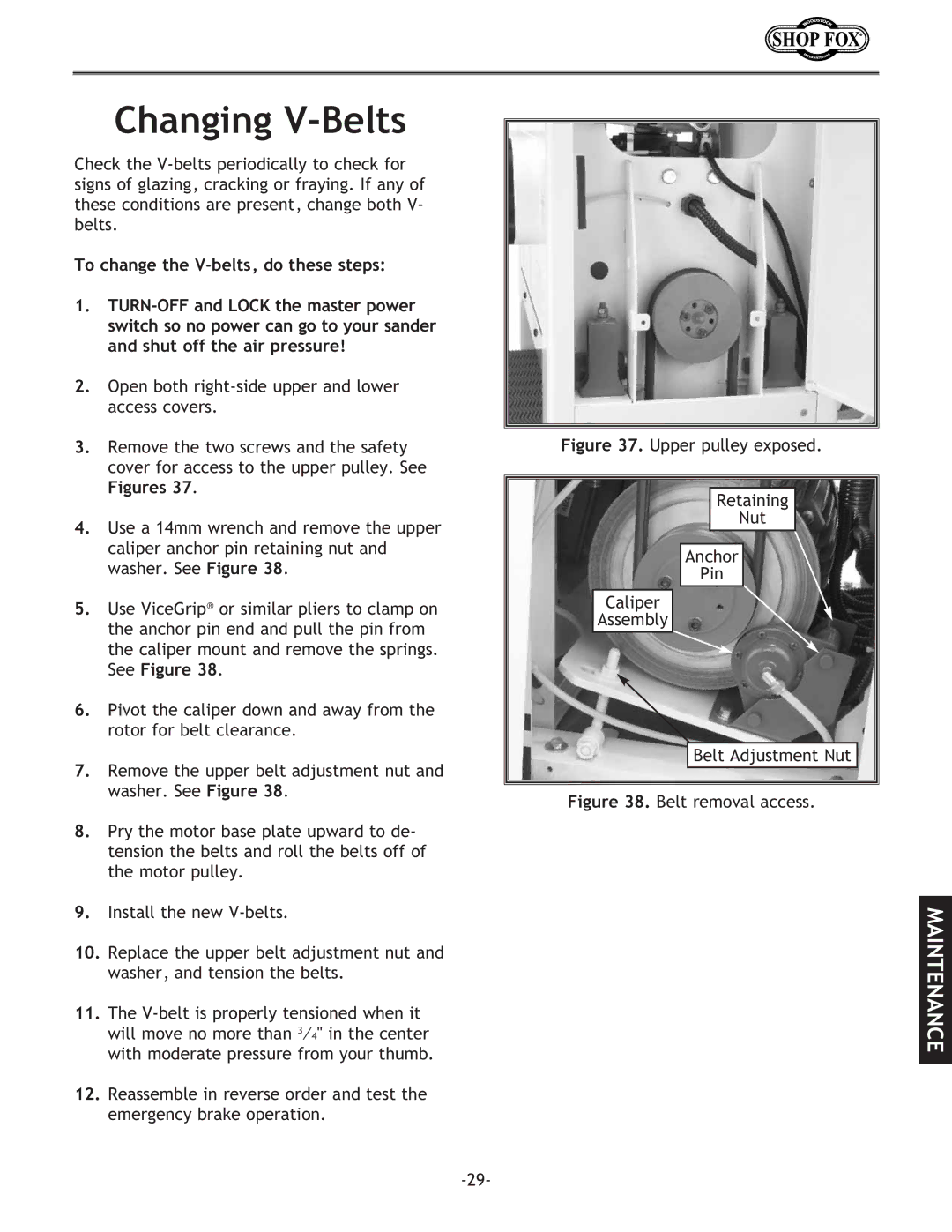

The belt tracking is adjusted by lengthening or shortening a air cylinder pushrod (Figure 14). This adjustment is responsible for keeping the belt in

KEEP your hands clear of the sanding belt when making these adjustments!

To adjust the belt tracking, do these steps:

1.Make sure the air flow is set to 57 PSI at the regulator.

2.Put on safety glasses, tie back all loose clothing, remove jewelry, pull back sleeves, and tie back long hair so it will not get caught by the sanding belt.

3.Turn the sander ON.

4.Observe the

•If the belt tracks faster to the right, but is slow to track back to the left, loosen the jam nut and rotate the pushrod to lengthen the rod until the tracking is correct. See Figure 14.

•If the belt tracks faster to the left, but is slow to track back to the right, loosen the jam nut and rotate the pushrod to shorten the rod until the tracking is correct. See Figure 14.

5.Make sure the belt tracks left and right at approximately the same speed.

6.Keep the sander running, and now complete the Belt Oscillation Speed adjustment as outlined on page 15.

KEEP loose clothing and long hair secured and away from moving parts.

Pushrod |

|

|

| Jam | |

|

| Nut |