OPERATIONS

Control Panel

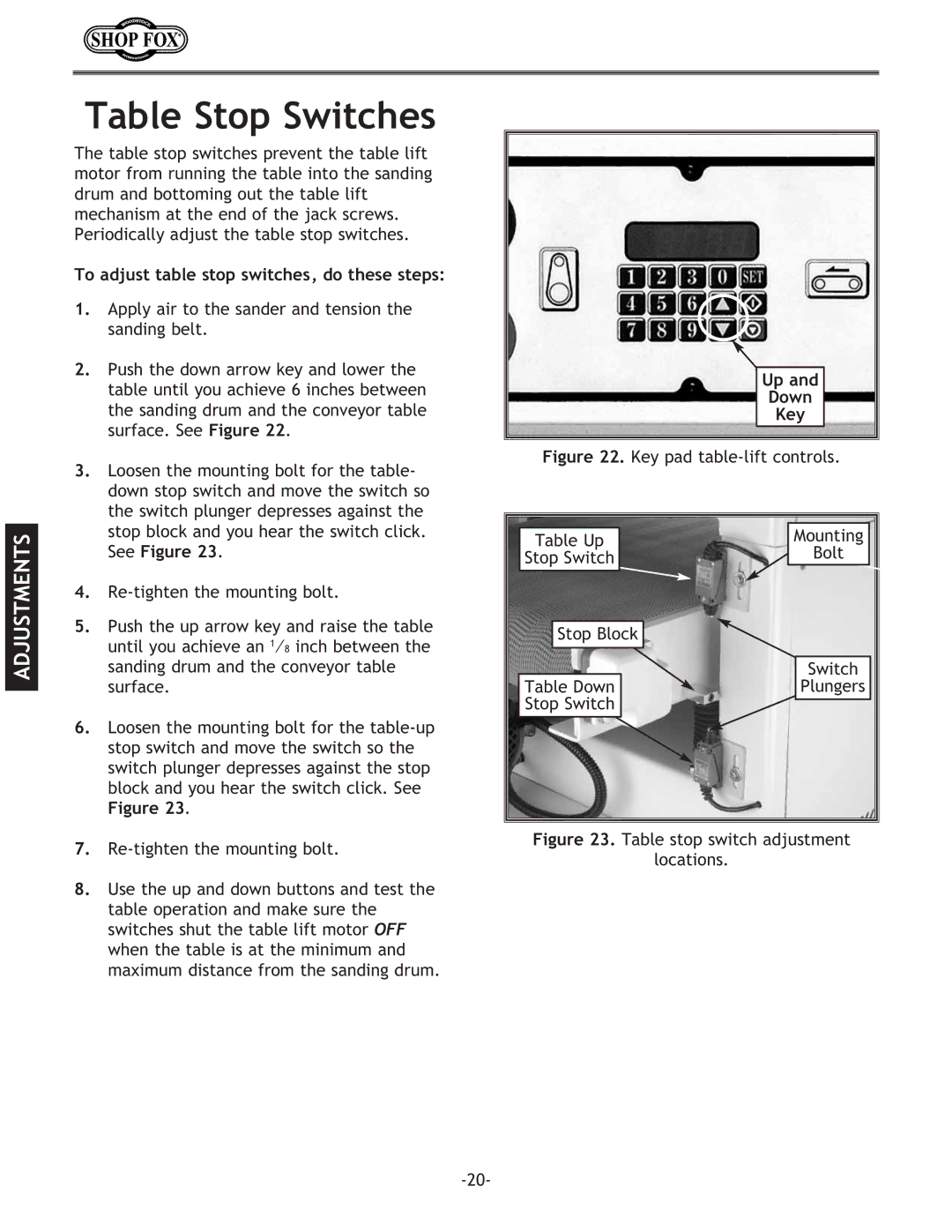

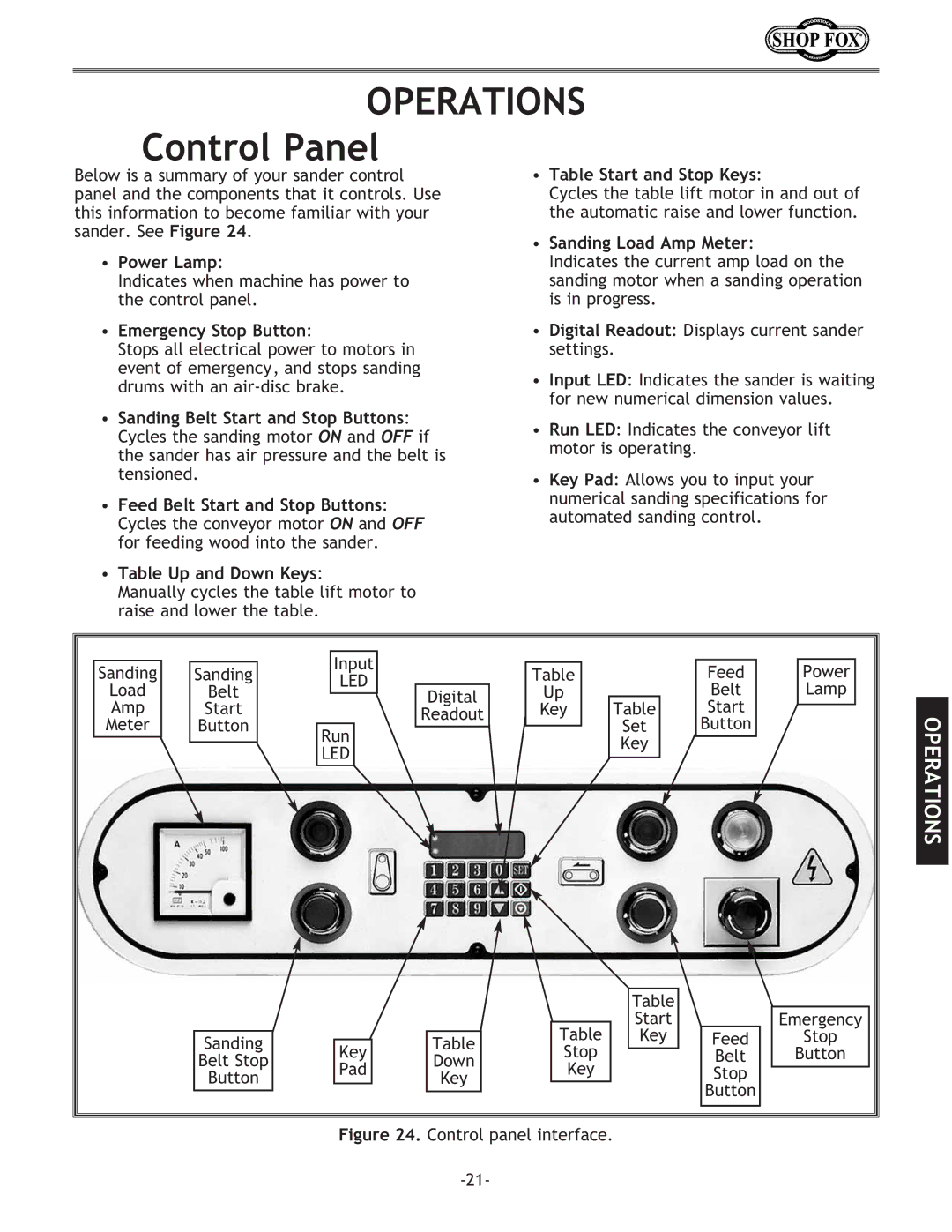

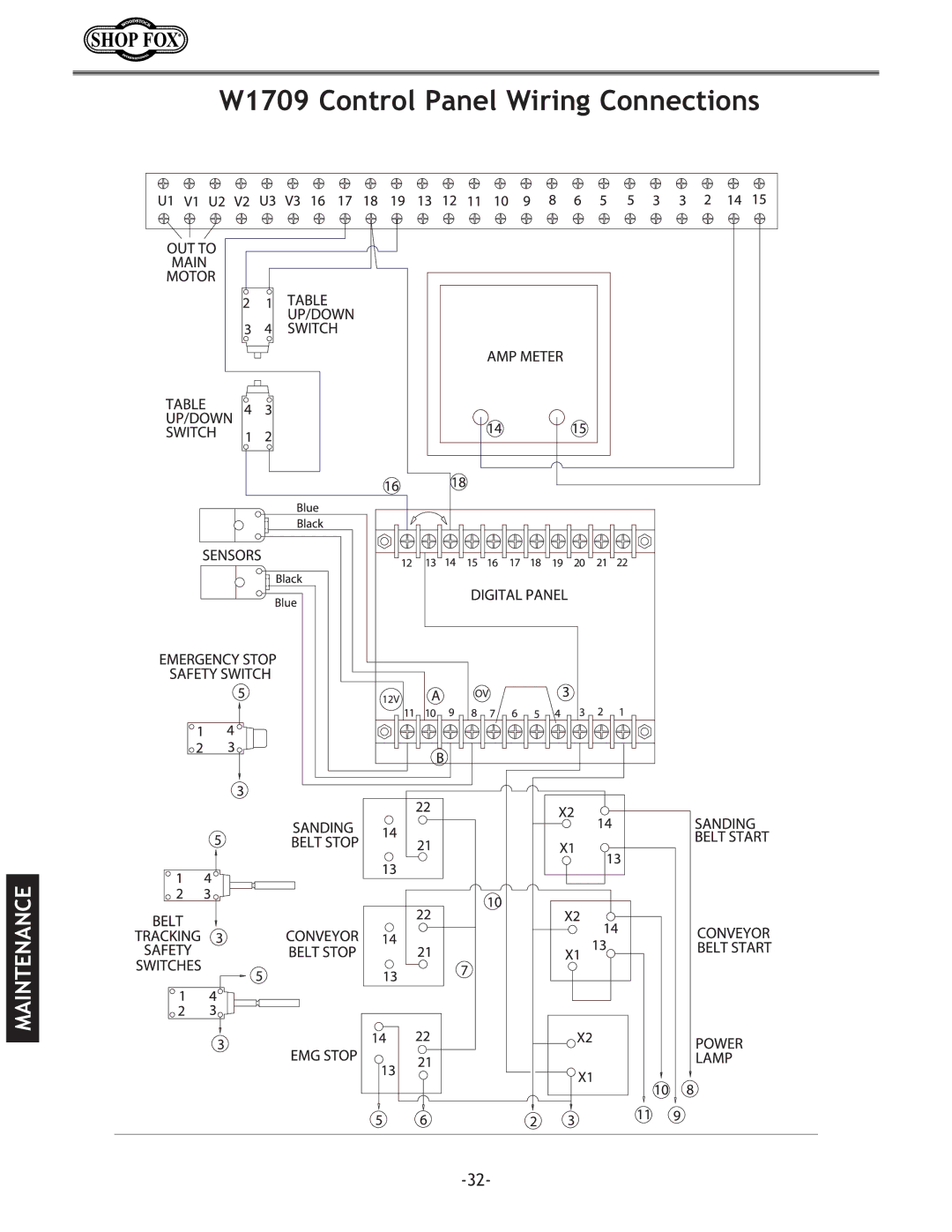

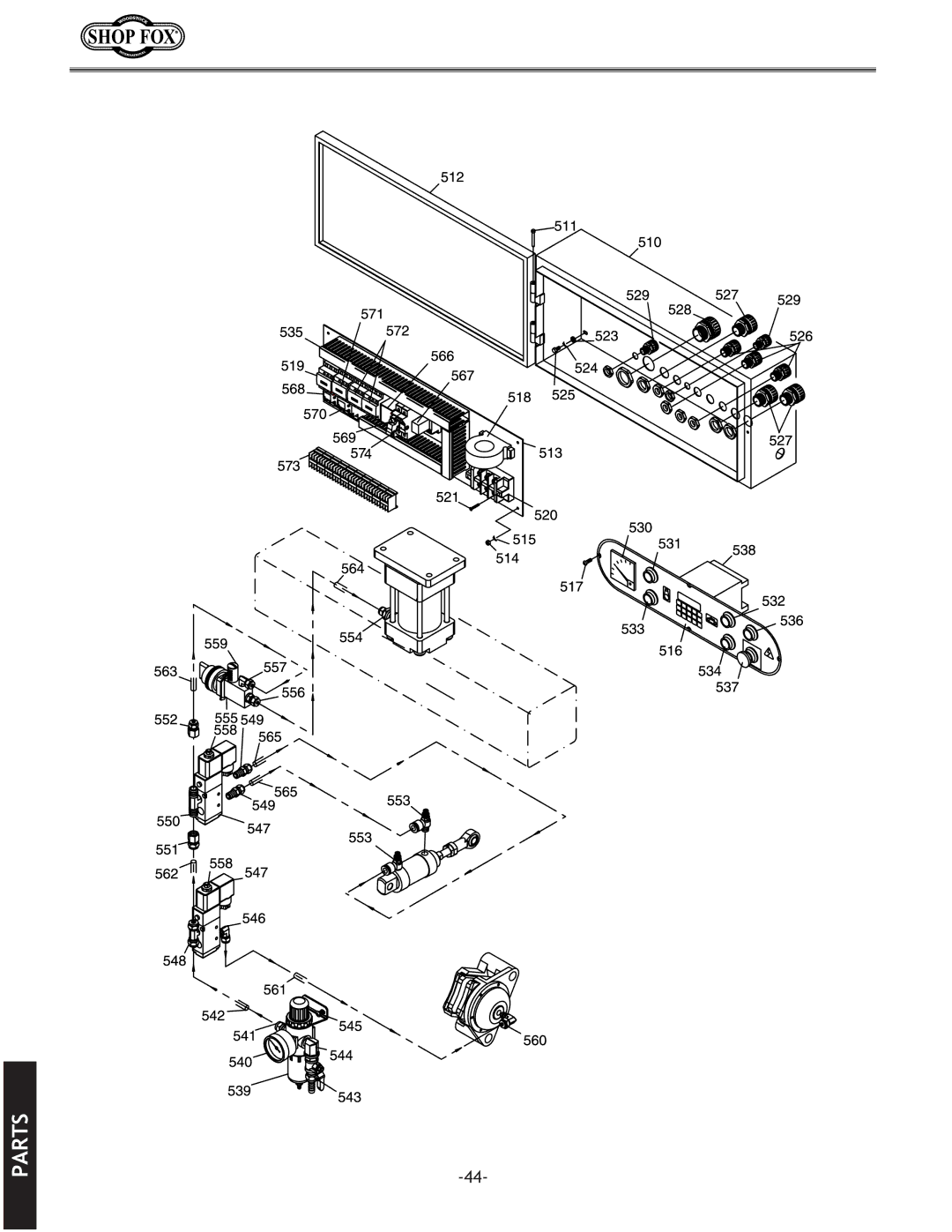

Below is a summary of your sander control panel and the components that it controls. Use this information to become familiar with your sander. See Figure 24.

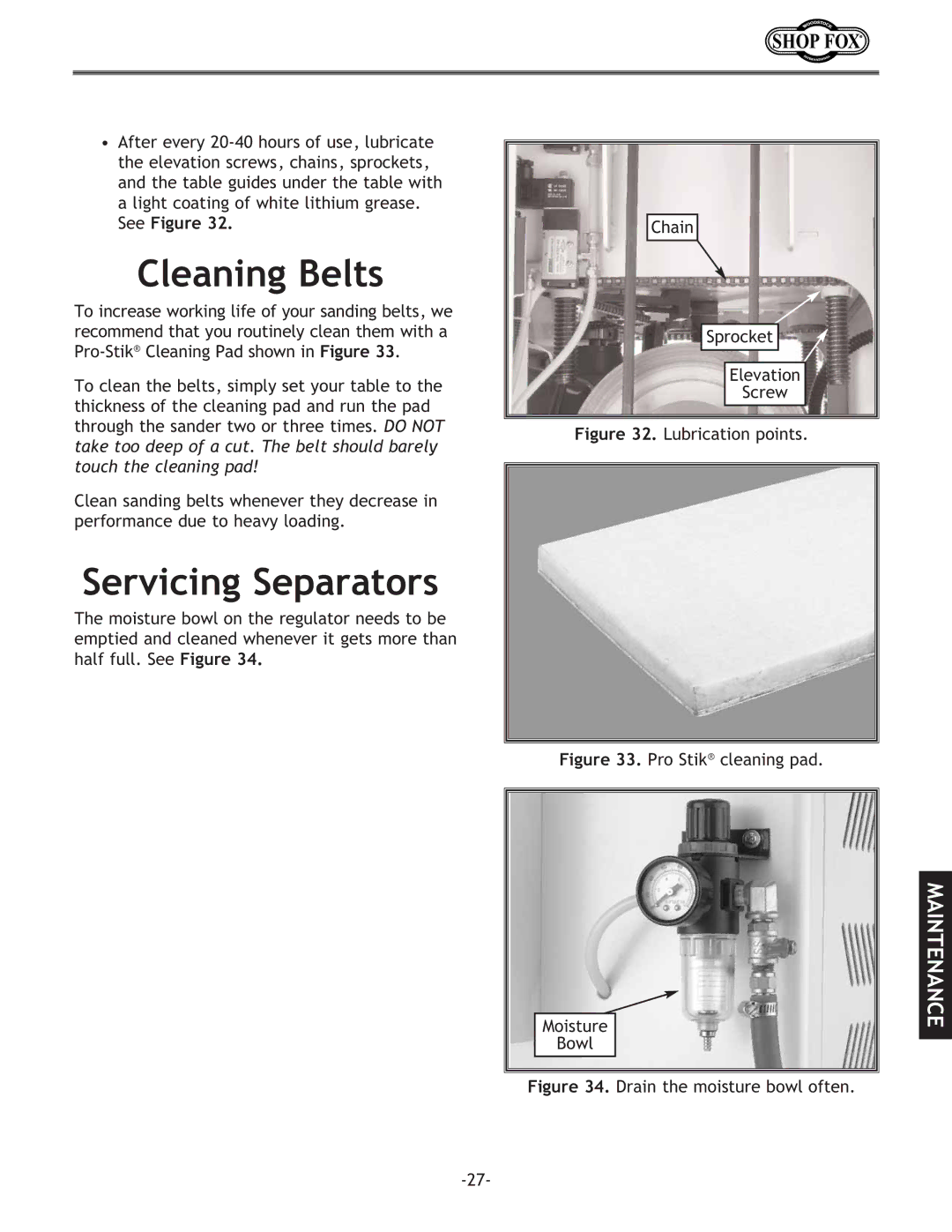

•Power Lamp:

Indicates when machine has power to the control panel.

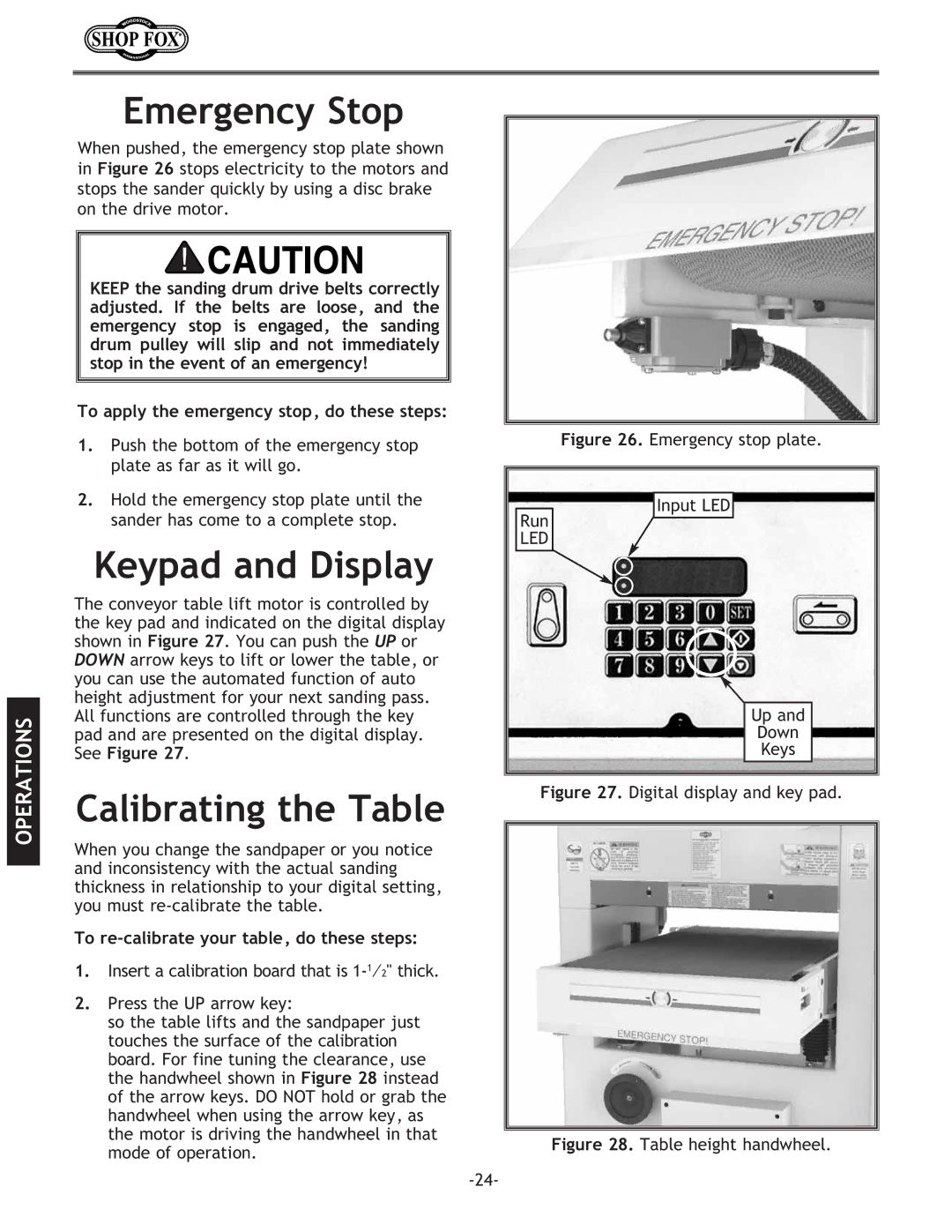

•Emergency Stop Button:

Stops all electrical power to motors in event of emergency, and stops sanding drums with an

•Sanding Belt Start and Stop Buttons: Cycles the sanding motor ON and OFF if the sander has air pressure and the belt is tensioned.

•Feed Belt Start and Stop Buttons: Cycles the conveyor motor ON and OFF for feeding wood into the sander.

•Table Up and Down Keys:

Manually cycles the table lift motor to raise and lower the table.

•Table Start and Stop Keys:

Cycles the table lift motor in and out of the automatic raise and lower function.

•Sanding Load Amp Meter:

Indicates the current amp load on the sanding motor when a sanding operation is in progress.

•Digital Readout: Displays current sander settings.

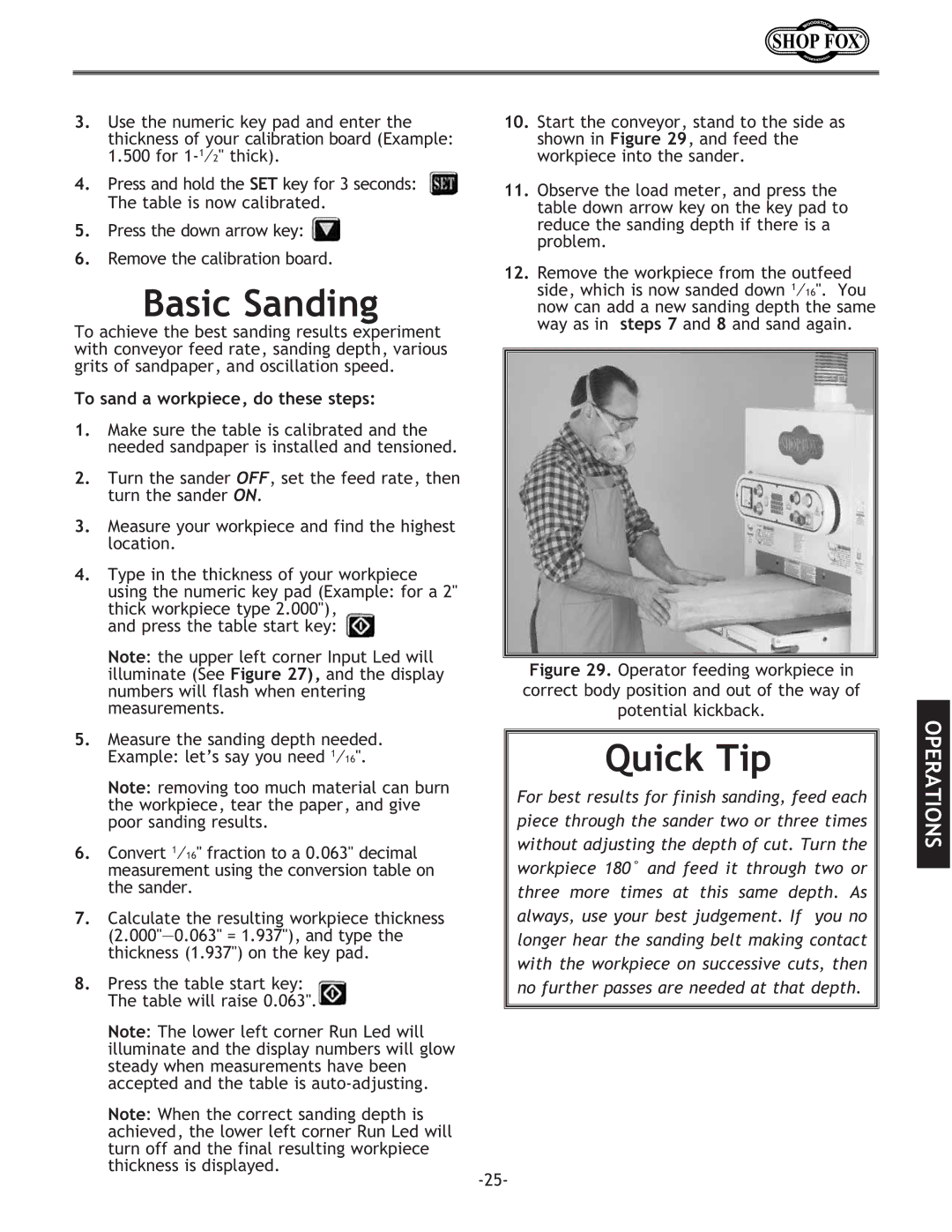

•Input LED: Indicates the sander is waiting for new numerical dimension values.

•Run LED: Indicates the conveyor lift motor is operating.

•Key Pad: Allows you to input your numerical sanding specifications for automated sanding control.

Sanding | Sanding | Input |

| Table |

| Feed | Power |

LED |

|

| |||||

Load | Belt | Digital | Up |

| Belt | Lamp | |

|

| ||||||

Amp | Start |

| Readout | Key | Table | Start | OPERATIONS |

Meter | Button | Run |

|

| Set | Button | |

|

|

|

| Key |

| ||

|

| LED |

|

|

| ||

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

|

|

|

|

| Table |

|

|

|

|

|

| Table | Start |

| Emergency |

| Sanding |

| Table | Key | Feed | Stop | |

| Belt Stop | Key | Down | Stop |

| Belt | Button |

| Button | Pad | Key | Key |

| Stop |

|

|

|

|

|

|

| Button |

|