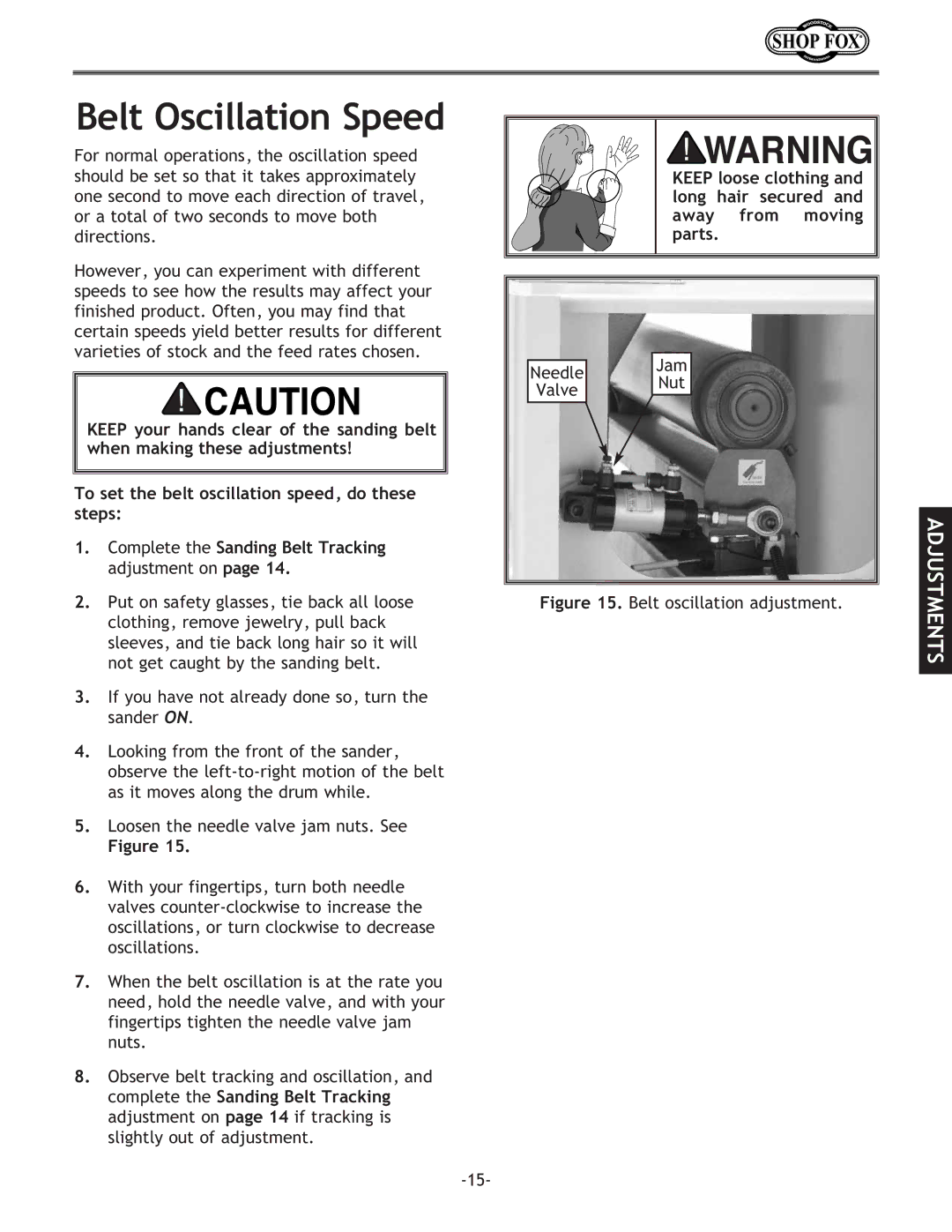

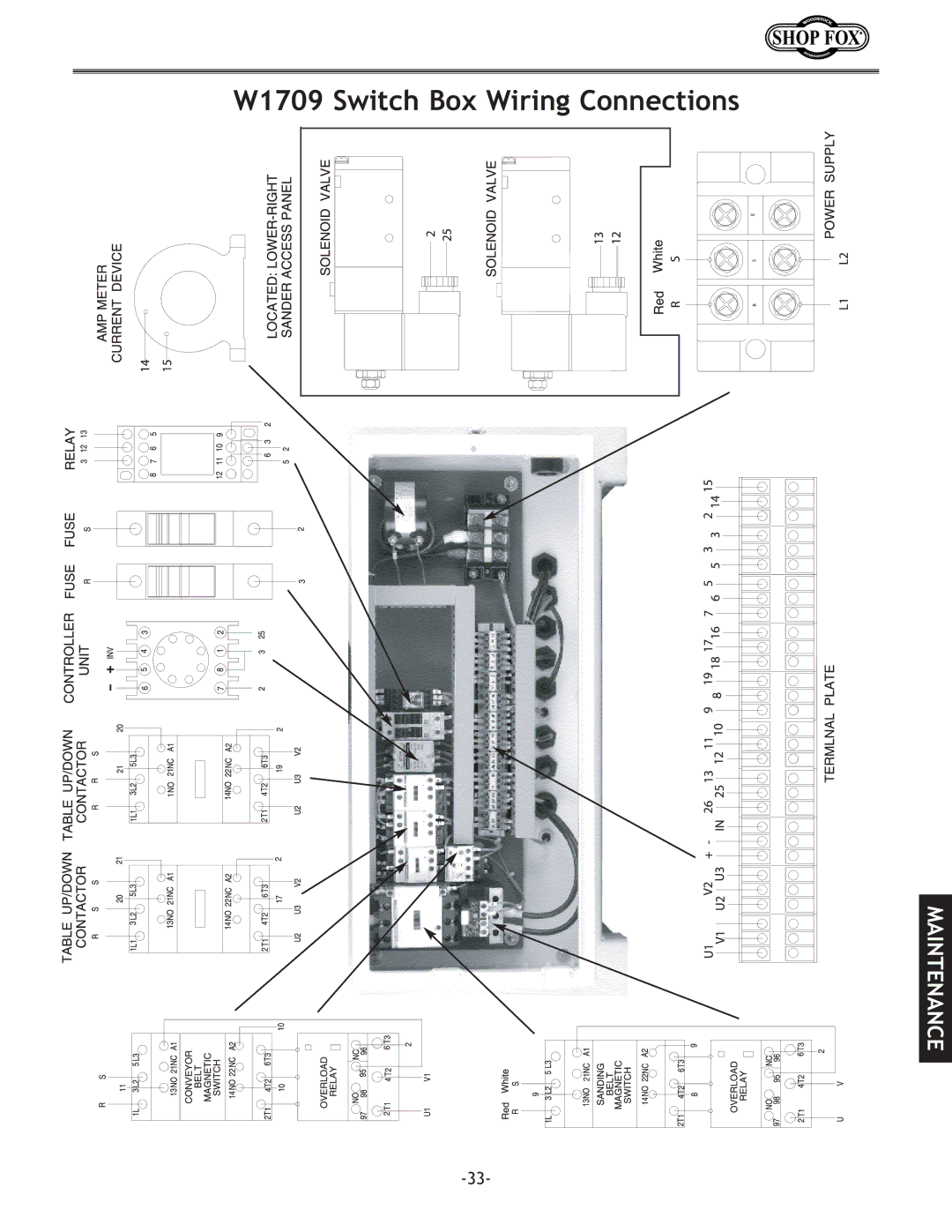

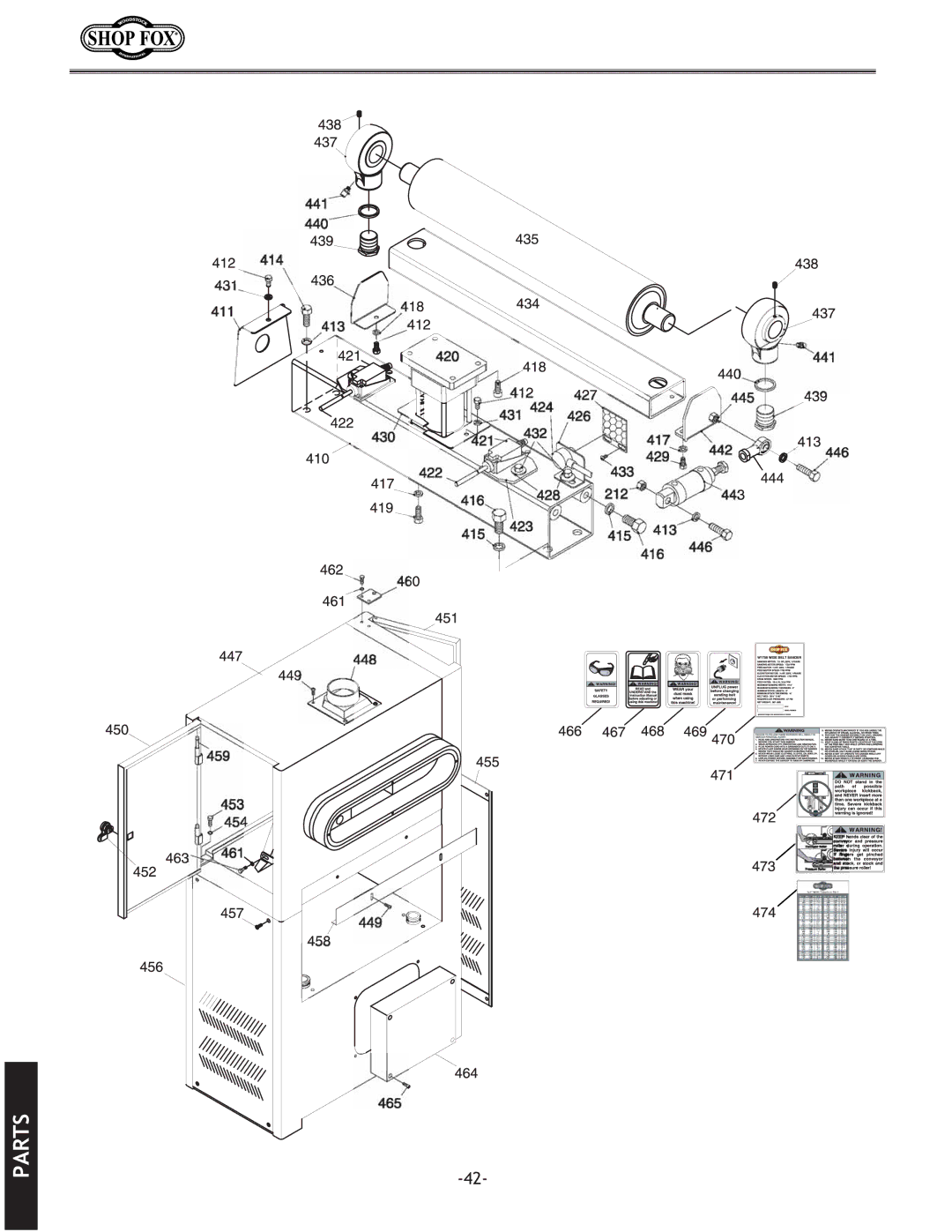

Feed Belt Tension

and Tracking

The feed belt tension and tracking has been set at the factory; however, if at any point you notice that your feed belt is slipping or tracking off center on the rollers and loading up on the positioning wheels under the conveyor table, you must adjust the feed belt tension and tracking.

To adjust the feed belt tension and tracking, do these steps:

1.Lift and hold the emergency stop plate up and out of the way. See Figure 21.

2.Turn the feed belt tension and tracking bolts equal amounts from

KEEP loose clothing and long hair secured and away from moving parts.

3.Start the conveyor.

4.Turn the feed belt tension and tracking bolt to position the feed belt roller evenly on each side. See Figure 21.

•If the conveyor tracks to the right, turn the

•If the conveyor tracks to the left, turn the

5.Run the feed belt for at least three minutes to determine if the tracking is correct and the tension stays the same.

6.Repeat steps as required to achieve the correct tension and tracking.

7.Test emergency stop operation.

Feed Belt

Tension and

Tracking Bolt

Figure 21. Feed belt tension bolt shown with

with the emergency brake raised.

ADJUSTMENTS