II. OPERATION

C. How To Use "Jam Cutting" (Fixed Cutting) and "Step Cutting" With Diamond Blades

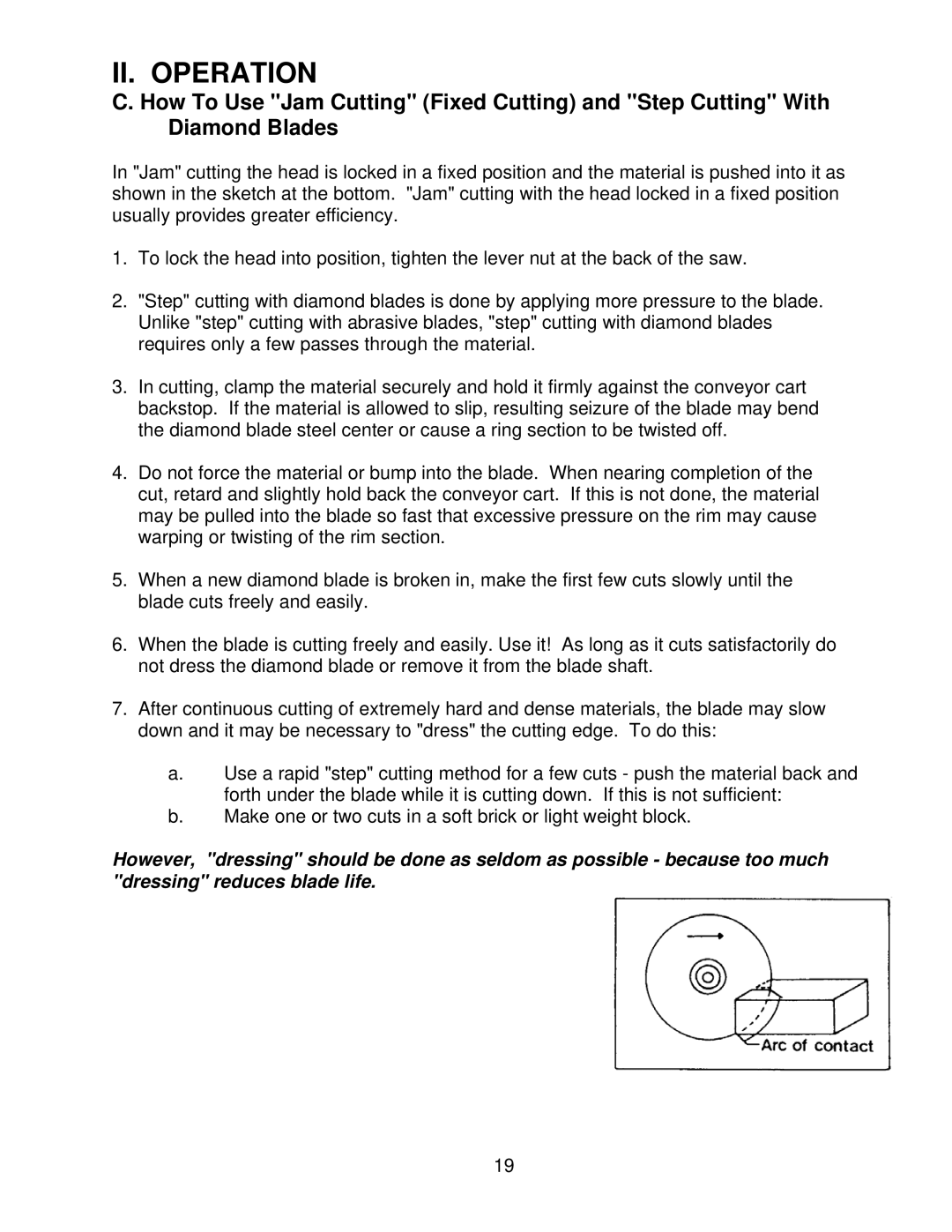

In "Jam" cutting the head is locked in a fixed position and the material is pushed into it as shown in the sketch at the bottom. "Jam" cutting with the head locked in a fixed position usually provides greater efficiency.

1.To lock the head into position, tighten the lever nut at the back of the saw.

2."Step" cutting with diamond blades is done by applying more pressure to the blade. Unlike "step" cutting with abrasive blades, "step" cutting with diamond blades requires only a few passes through the material.

3.In cutting, clamp the material securely and hold it firmly against the conveyor cart backstop. If the material is allowed to slip, resulting seizure of the blade may bend the diamond blade steel center or cause a ring section to be twisted off.

4.Do not force the material or bump into the blade. When nearing completion of the cut, retard and slightly hold back the conveyor cart. If this is not done, the material may be pulled into the blade so fast that excessive pressure on the rim may cause warping or twisting of the rim section.

5.When a new diamond blade is broken in, make the first few cuts slowly until the blade cuts freely and easily.

6.When the blade is cutting freely and easily. Use it! As long as it cuts satisfactorily do not dress the diamond blade or remove it from the blade shaft.

7.After continuous cutting of extremely hard and dense materials, the blade may slow down and it may be necessary to "dress" the cutting edge. To do this:

a.Use a rapid "step" cutting method for a few cuts - push the material back and forth under the blade while it is cutting down. If this is not sufficient:

b.Make one or two cuts in a soft brick or light weight block.

However, "dressing" should be done as seldom as possible - because too much "dressing" reduces blade life.

19