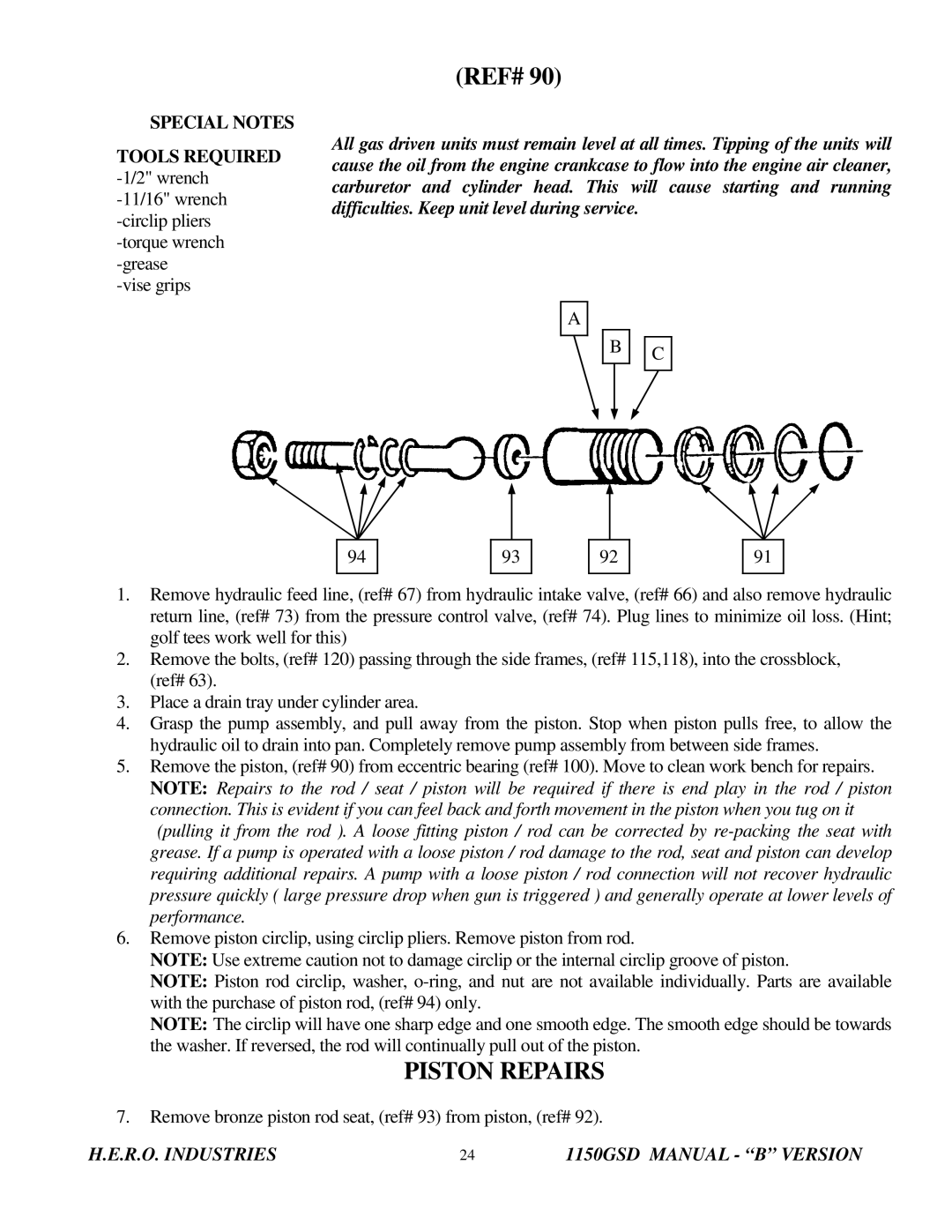

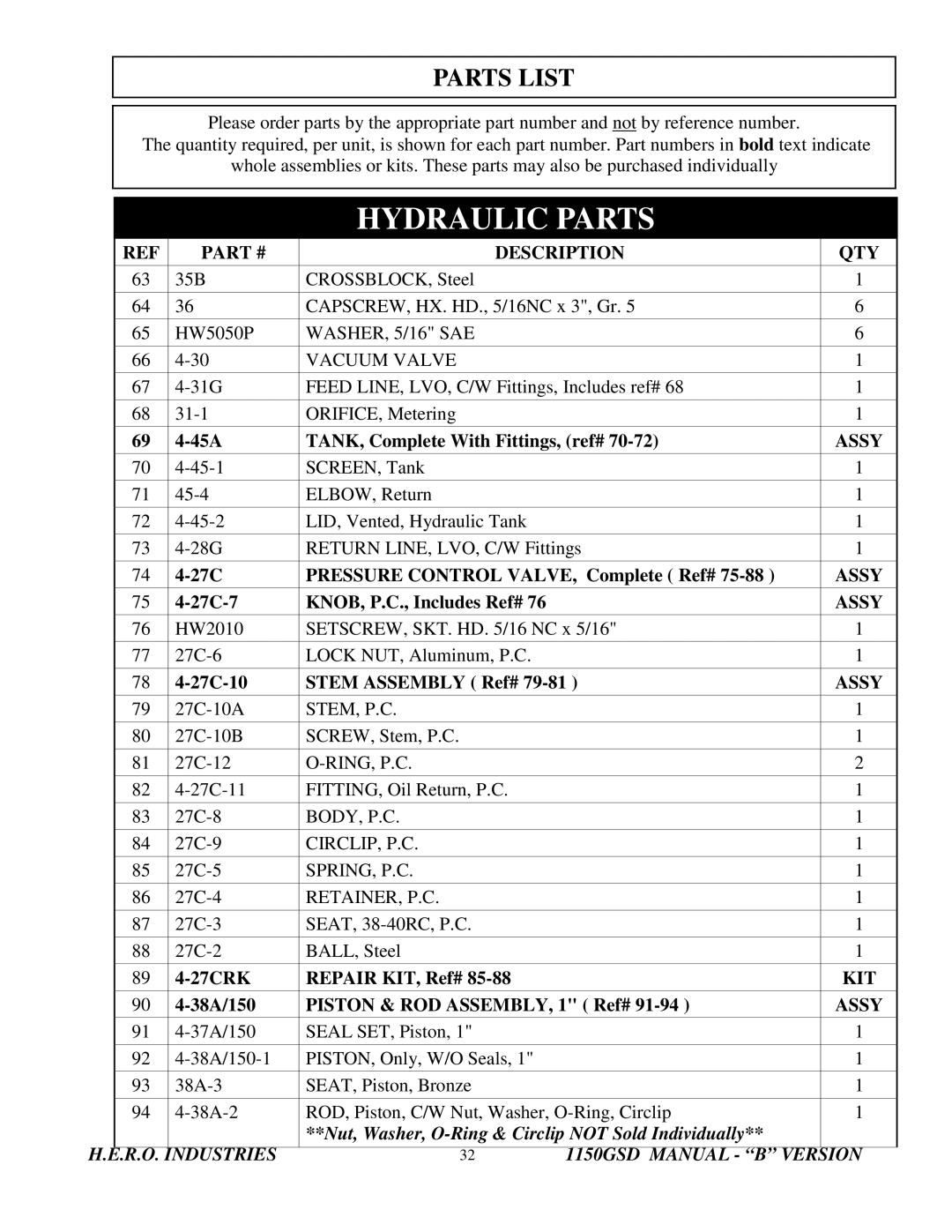

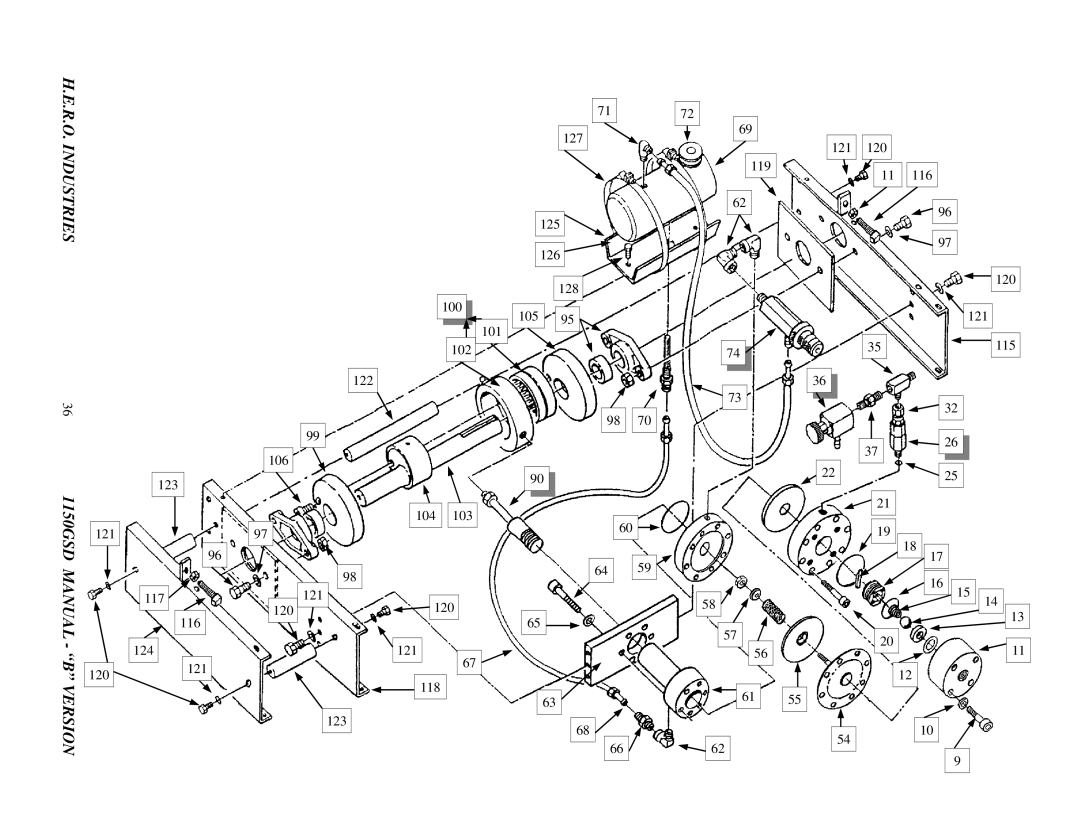

(REF# 90)

SPECIAL NOTES

TOOLS REQUIRED

All gas driven units must remain level at all times. Tipping of the units will cause the oil from the engine crankcase to flow into the engine air cleaner, carburetor and cylinder head. This will cause starting and running difficulties. Keep unit level during service.

A

B | C |

|

94

93

92

91

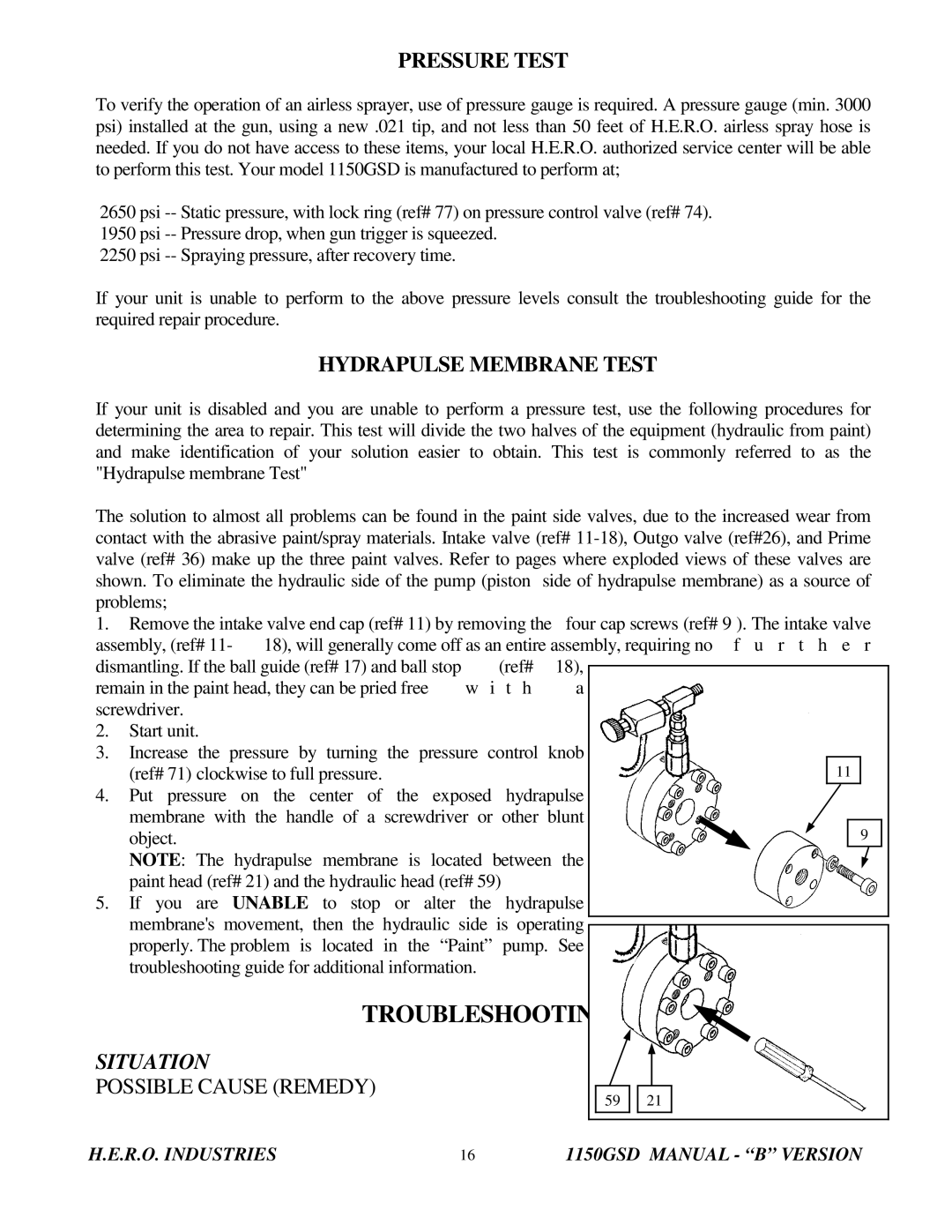

1.Remove hydraulic feed line, (ref# 67) from hydraulic intake valve, (ref# 66) and also remove hydraulic return line, (ref# 73) from the pressure control valve, (ref# 74). Plug lines to minimize oil loss. (Hint; golf tees work well for this)

2.Remove the bolts, (ref# 120) passing through the side frames, (ref# 115,118), into the crossblock, (ref# 63).

3.Place a drain tray under cylinder area.

4.Grasp the pump assembly, and pull away from the piston. Stop when piston pulls free, to allow the hydraulic oil to drain into pan. Completely remove pump assembly from between side frames.

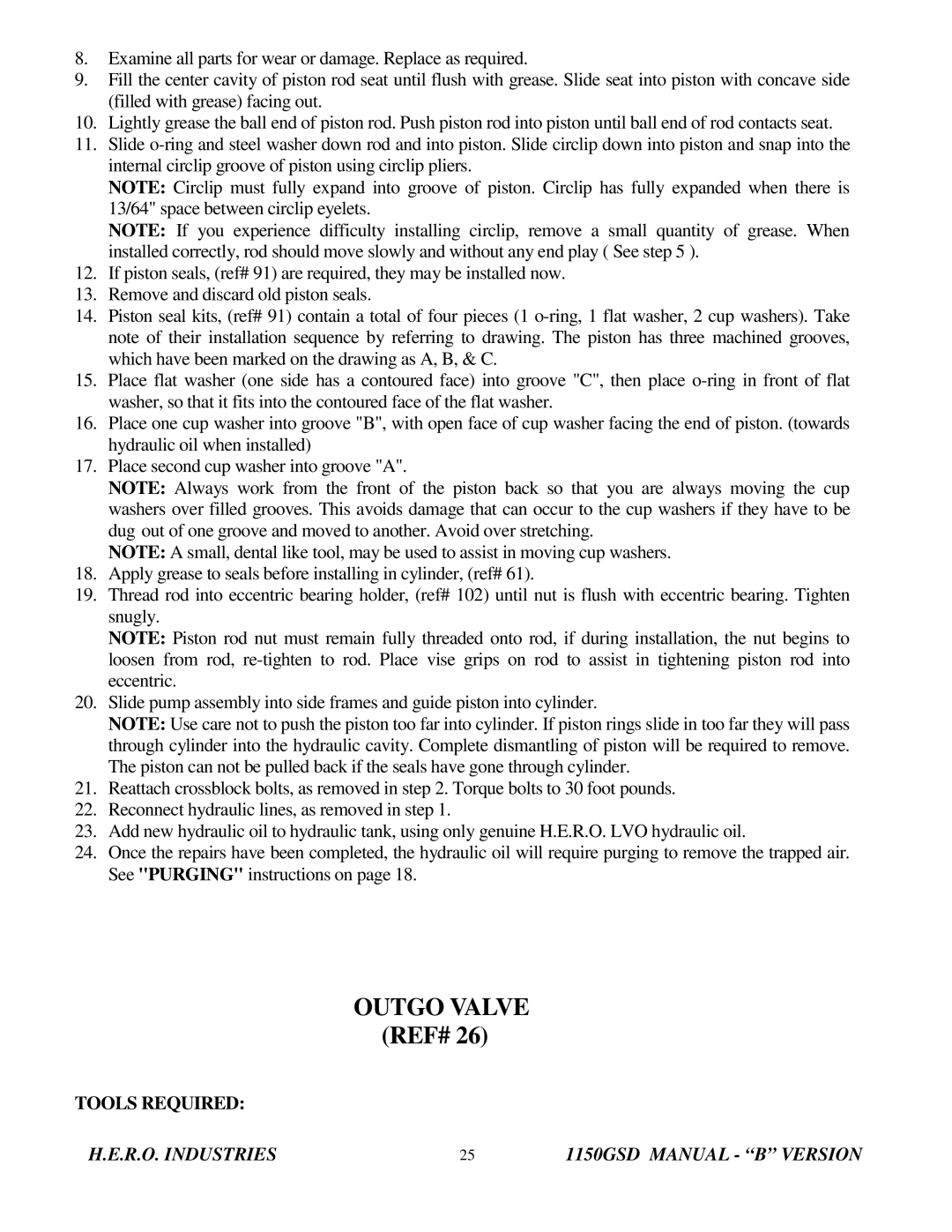

5.Remove the piston, (ref# 90) from eccentric bearing (ref# 100). Move to clean work bench for repairs. NOTE: Repairs to the rod / seat / piston will be required if there is end play in the rod / piston connection. This is evident if you can feel back and forth movement in the piston when you tug on it (pulling it from the rod ). A loose fitting piston / rod can be corrected by

6.Remove piston circlip, using circlip pliers. Remove piston from rod.

NOTE: Use extreme caution not to damage circlip or the internal circlip groove of piston.

NOTE: Piston rod circlip, washer,

NOTE: The circlip will have one sharp edge and one smooth edge. The smooth edge should be towards the washer. If reversed, the rod will continually pull out of the piston.

PISTON REPAIRS

7.Remove bronze piston rod seat, (ref# 93) from piston, (ref# 92).

H.E.R.O. INDUSTRIES | 24 | 1150GSD MANUAL - “B” VERSION |