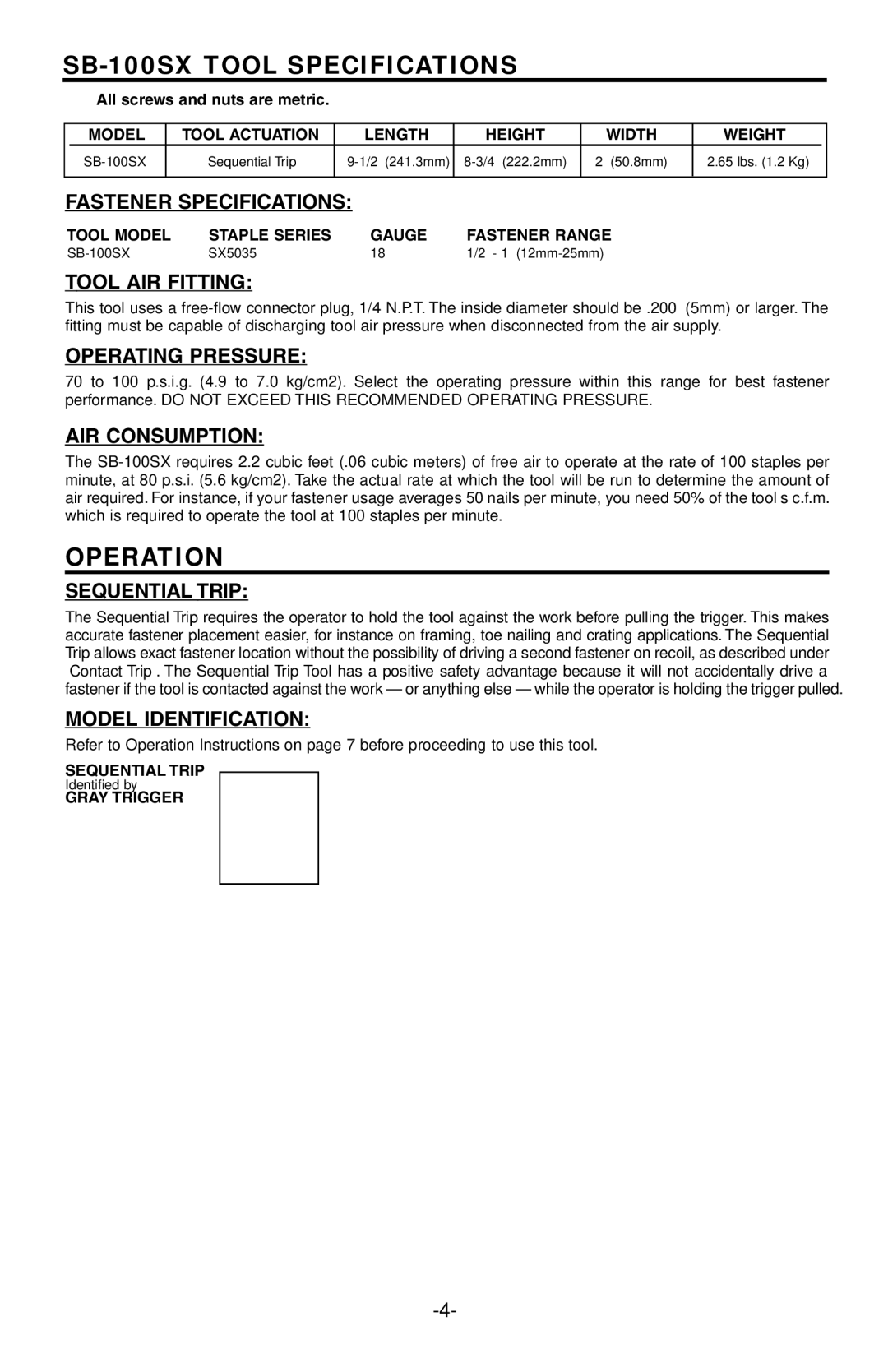

TOOL OPERATION

EYE PROTECTION which conforms to ANSI specifications and provides protection against flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and others in the work area when connecting to air supply, loading, operating or servicing this tool. Eye protection is required to guard against flying fasteners and debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must conform to the requirements of the American National Standards Institute, ANSI Z87.1 and provide both frontal and side protection. NOTE:

BEFORE HANDLING OR OPERATING THIS TOOL:

I.READ AND UNDERSTAND THE WARNINGS CONTAINED IN THIS MANUAL.

II.REFER TO “TOOL SPECIFICATIONS” IN THIS MANUAL TO IDENTIFY THE OPERATING SYSTEM ON YOUR TOOL.

OPERATION

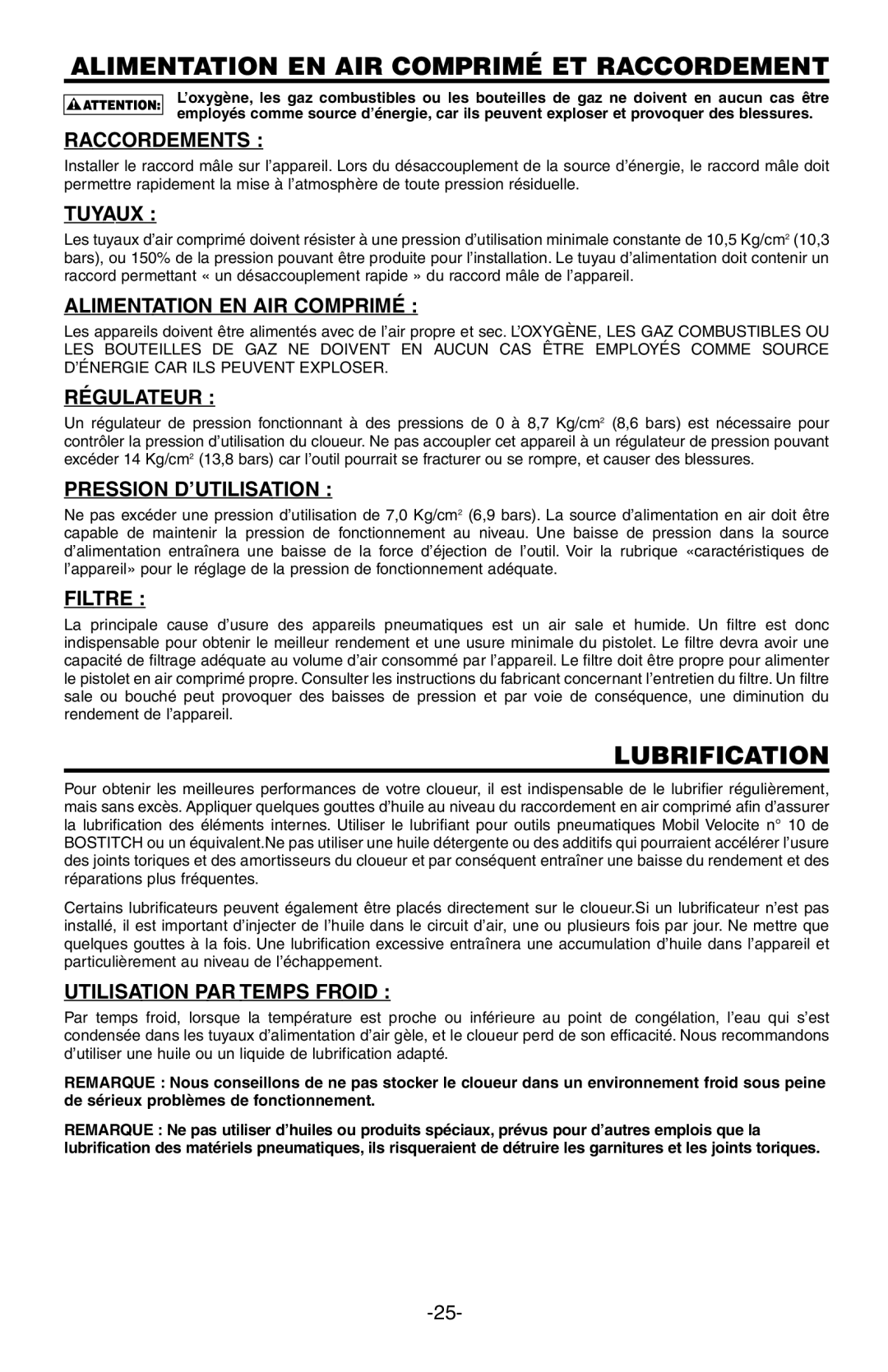

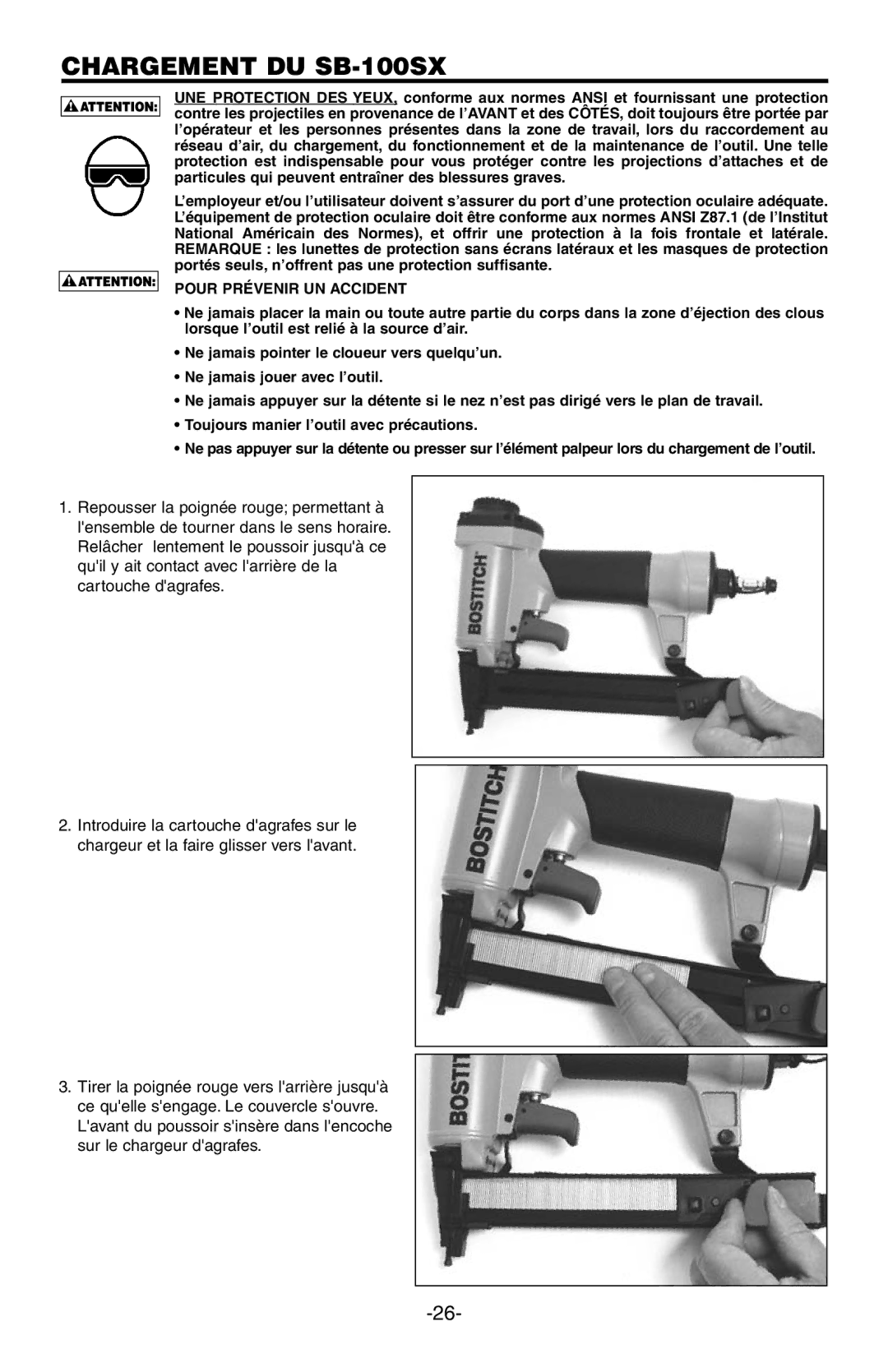

SEQUENTIAL TRIP OPERATION:

The SEQUENTIAL TRIP MODEL contains a contact trip that operates in conjunction with the trigger to drive a fastener. To operate a sequential trip tool, first position the contact trip on the work surface WITHOUT PULLING THE TRIGGER. Depress the contact trip and then pull the trigger to drive a fastener. As long as the contact trip is contacting the work and is held depressed, the tool will drive a fastener each time the trigger is depressed. If the contact trip is allowed to leave the work surface, the sequence described above must be repeated to drive another fastener.