Repair | P 18 / 22 |

|

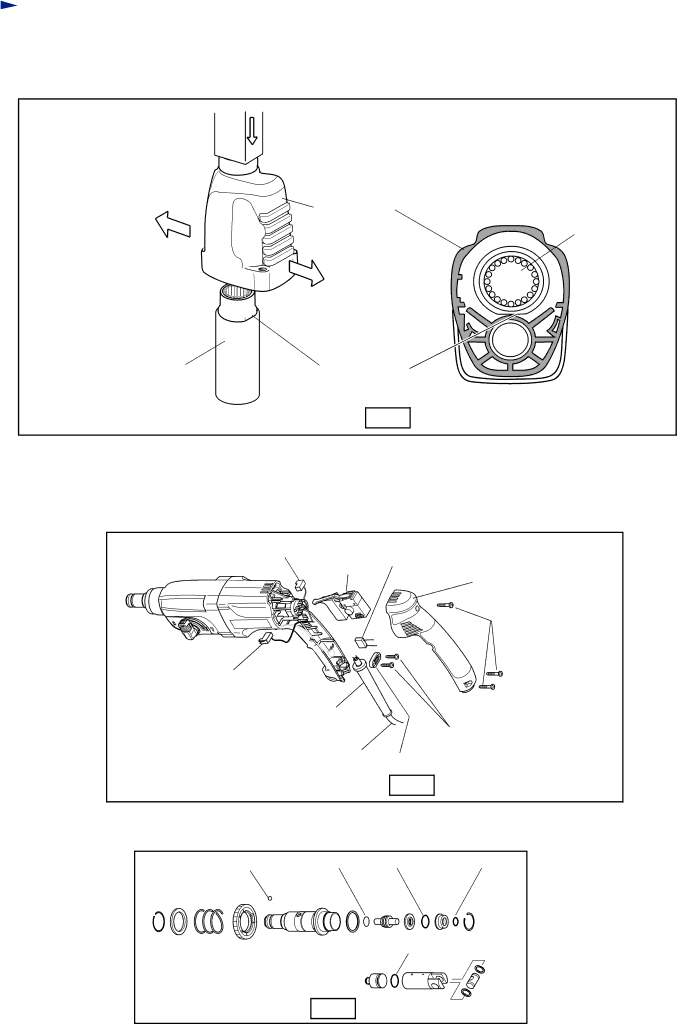

<18 > Assembling needle bearing complete

1.Apply MAKITA grease RA No.1 to the inside of needle baring complete.

2.Putting needle bearing complete on No.1R165 "Ring spring setting tool B" press gear housing onto the needle bearing complete with arbor press as illustrated in Fig. 79.

Back side

Needle bearing ![]() complete

complete

No.1R165

Ring spring setting tool B

< Note in assembling >

Pay attention to the assembling position of needle bearing complete.

The fat portion of needle bearing complete has to be faced to the belly side of gear housing.

Gear housing | Back side |

Needle bearing complete.

Belly side

Flat portion of  needle bearing complete

needle bearing complete

Belly side

Fig. 79

< 19 > Replacing electrical parts in handle

Disassemble handle cover by unscrewing 3 pcs. of tapping screws 4x25, and disassemble strain relief by unscrewing 2 pcs. of tapping screws 4x18 as illustrated in Fig.80.

Then, switch, noise suppressor, power supply cord, etc. can be replaced.

Brush holder

Switch

Brush holder

Cord guard

Power supply cord

Noise suppressor

Handle cover

Tapping s

crew 4 x 25 : 3 pcs.

Tapping screw 4x18 : 2 pcs.

Strain relief

Fig. 80

< 18 > Maintenance

It is recommended to change the following parts, when replacing carbon brushes. See Fig. 81.

Steel ball 7.0 | O ring 12 O ring 15 | O ring 9 |

|

|

O ring 16

Fig. 81