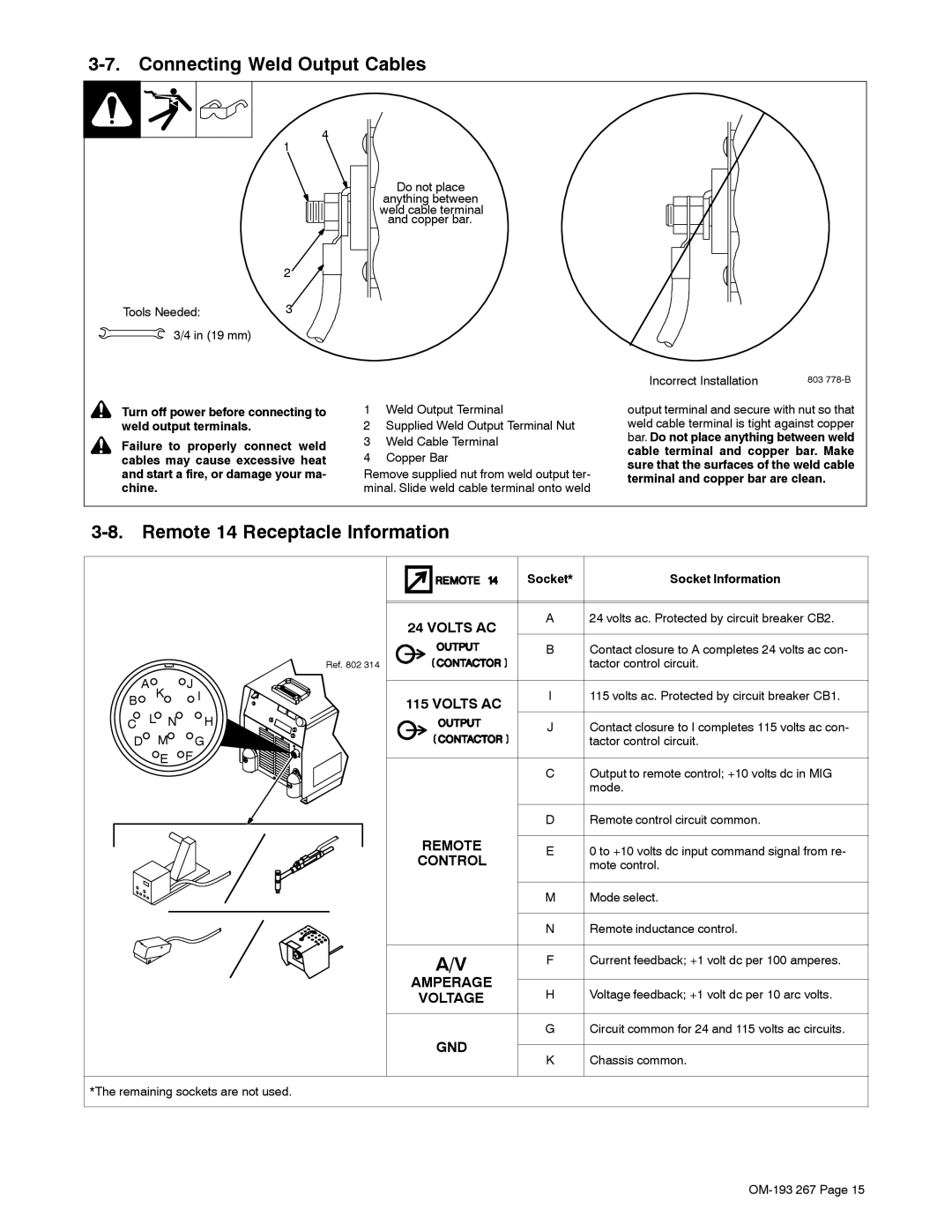

3-9. 115 Volts AC Duplex Receptacle and Circuit Breakers

1 | 2 | 3 |

|

1 115 V 10 A AC Receptacle

Power is shared between duplex receptacle and Remote 14 recep- tacle (see Section

2Circuit Breaker CB1

3Circuit Breaker CB2

CB1 protects duplex receptacle and 115 volts ac portion of Remote 14 receptacle from overload.

CB2 protects 24 volts ac portion of Remote 14 receptacle from overload.

Press button to reset breaker.

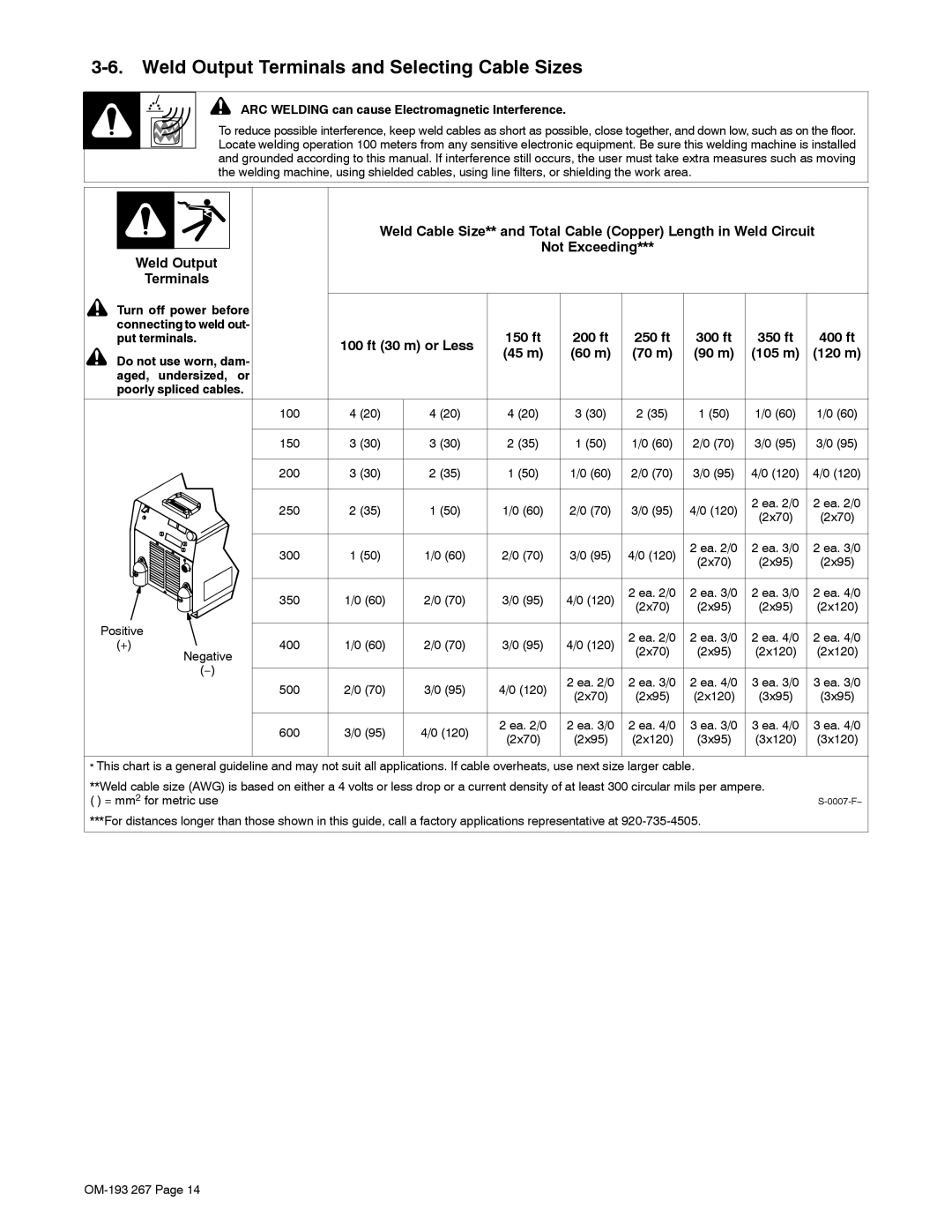

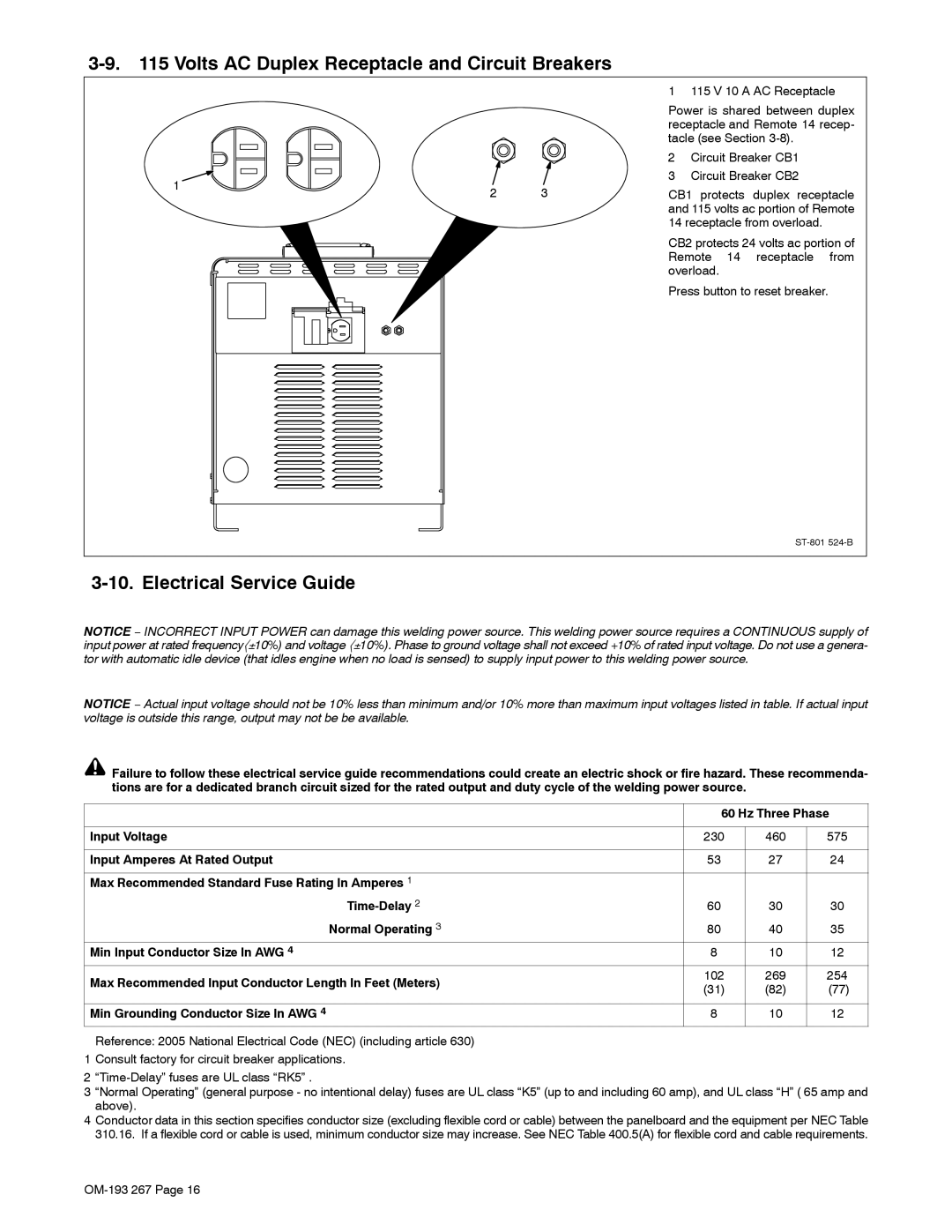

3-10. Electrical Service Guide

NOTICE − INCORRECT INPUT POWER can damage this welding power source. This welding power source requires a CONTINUOUS supply of input power at rated frequency(+10%) and voltage (+10%). Phase to ground voltage shall not exceed +10% of rated input voltage. Do not use a genera- tor with automatic idle device (that idles engine when no load is sensed) to supply input power to this welding power source.

NOTICE − Actual input voltage should not be 10% less than minimum and/or 10% more than maximum input voltages listed in table. If actual input voltage is outside this range, output may not be be available.

![]() Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source.

| 60 Hz Three Phase | |||

|

|

|

| |

Input Voltage | 230 | 460 | 575 | |

|

|

|

| |

Input Amperes At Rated Output | 53 | 27 | 24 | |

|

|

|

| |

Max Recommended Standard Fuse Rating In Amperes 1 |

|

|

| |

60 | 30 | 30 | ||

Normal Operating 3 | 80 | 40 | 35 | |

Min Input Conductor Size In AWG 4 | 8 | 10 | 12 | |

Max Recommended Input Conductor Length In Feet (Meters) | 102 | 269 | 254 | |

(31) | (82) | (77) | ||

| ||||

|

|

|

| |

Min Grounding Conductor Size In AWG 4 | 8 | 10 | 12 | |

Reference: 2005 National Electrical Code (NEC) (including article 630) |

|

|

| |

1Consult factory for circuit breaker applications.

2

3“Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and above).

4Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table 310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.