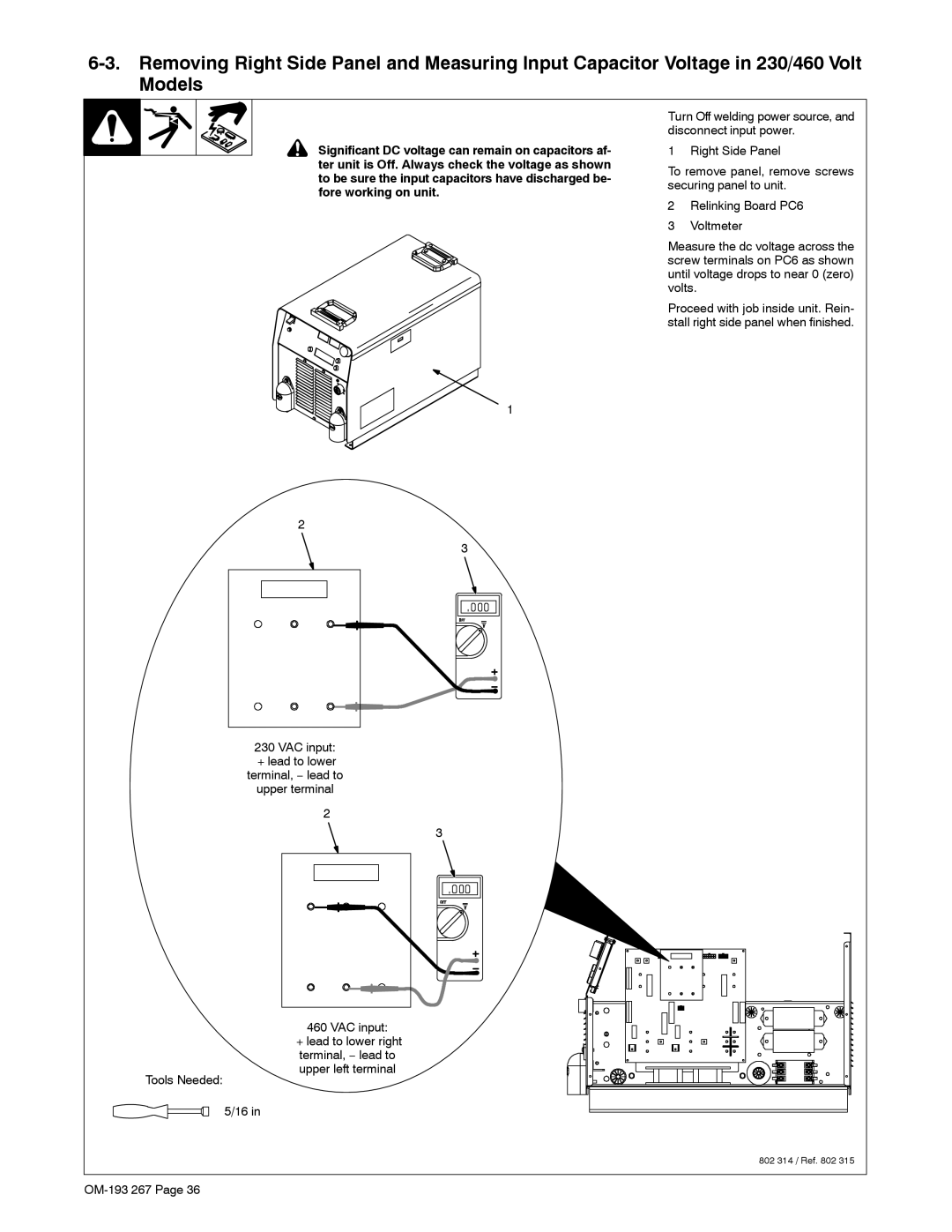

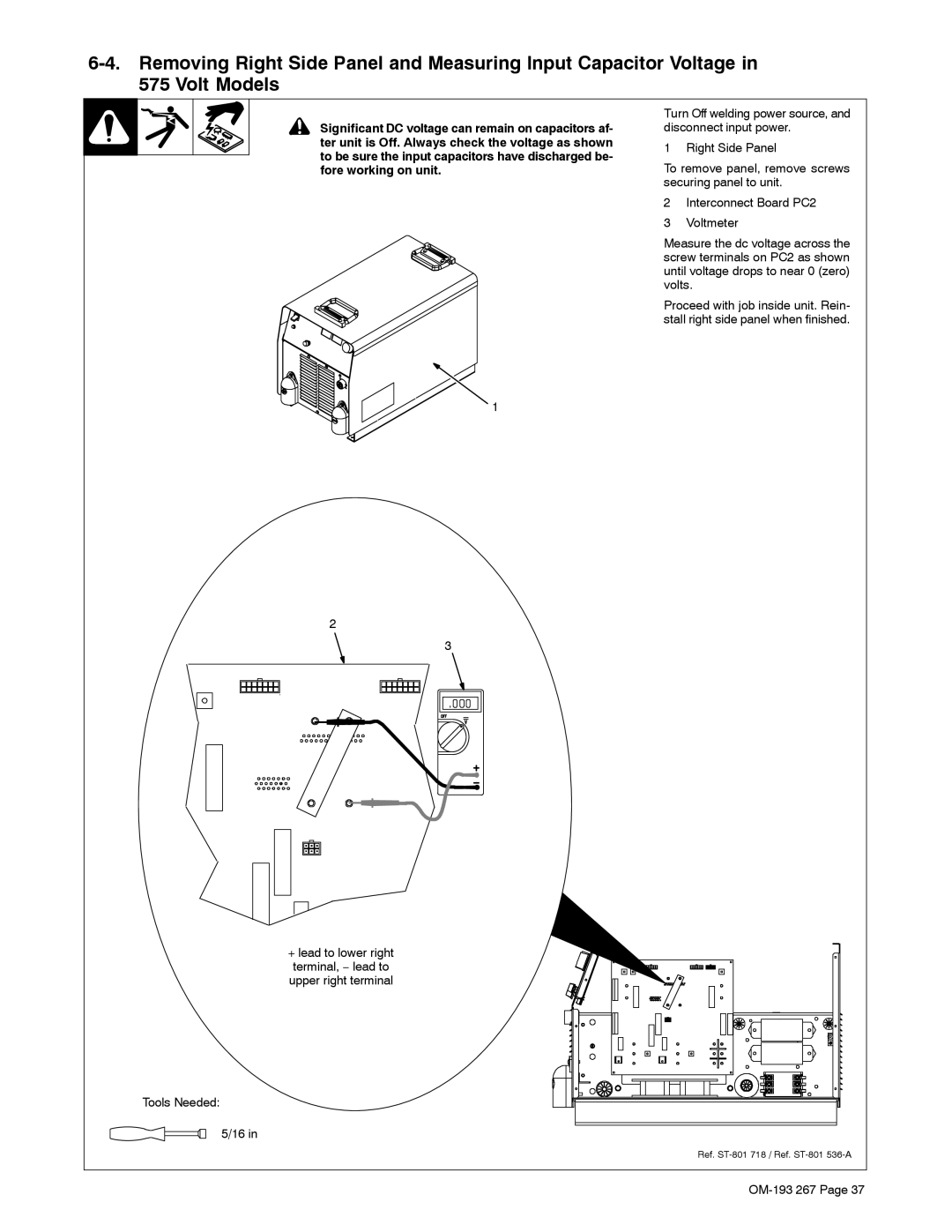

SECTION 6 − MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

! Disconnect power before maintaining.

.Maintain more often during severe conditions.

3 Months

Replace damaged or unreadable label.

Repair or replace cracked cables.

Replace cracked torch body.

Repair or replace cracked cables and cords.

Clean and tighten weld terminals.

6 Months

Blow out inside.

6-2. Blowing Out Inside of Unit

! Do not remove case when blowing out inside of unit.

To blow out unit, direct airflow through front and back louvers as shown.

802 314