Installing Crank

Handle

Components and Hardware Needed: | Qty |

Crank Handle | 1 |

The crank handle is installed on the front right lift screw shaft, and is held in place with two set screws already threaded into the handle.

To mount the handwheel:

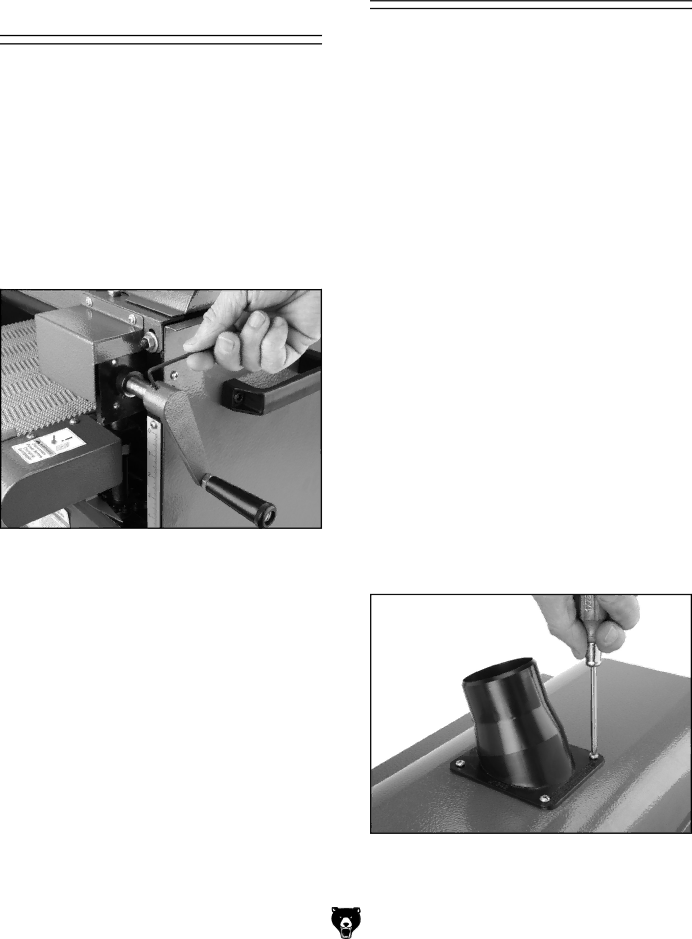

1.Place the crank handle over the shaft shown in Figure 6 and, using a 3mm hex wrench, secure the handle with the two set screws.

Figure 6. Crank handle installation.

G0459 12" Drum Sander

Dust Collection | ||

Components and Hardware Needed: | Qty | |

Dust Hoses 21⁄2" (not included) | Length Varies | |

Hose Clamps (not included) | Varies | |

Dust Collection System (not included) | 1 | |

This drum sander requires a minimum of 400

CFM AT THE DUST PORT.

Note: Do not confuse this CFM recommendation with the rating of the dust collector. To determine the CFM at the dust port, you must take into account many variables, including the rating of the dust collector, the length of hose between the dust collector and the machine, the amount of branches or wyes, and the amount of other open lines throughout the system.

A fine layer of dust will be present on your stock as it comes out of the sander. This is normal.

To connect the dust port to a dust collector:

1.Remove the four Phillips head screws at the dust port hole.

2.Place the 21⁄2" dust port over the top cover mounting holes and secure with the Phillips head screws removed in Step 1 as shown in Figure 7.

3.Attach a 21⁄2" dust collection hose to the dust port and secure it with a hose clamp.