7800 SERIES RELAY MODULES

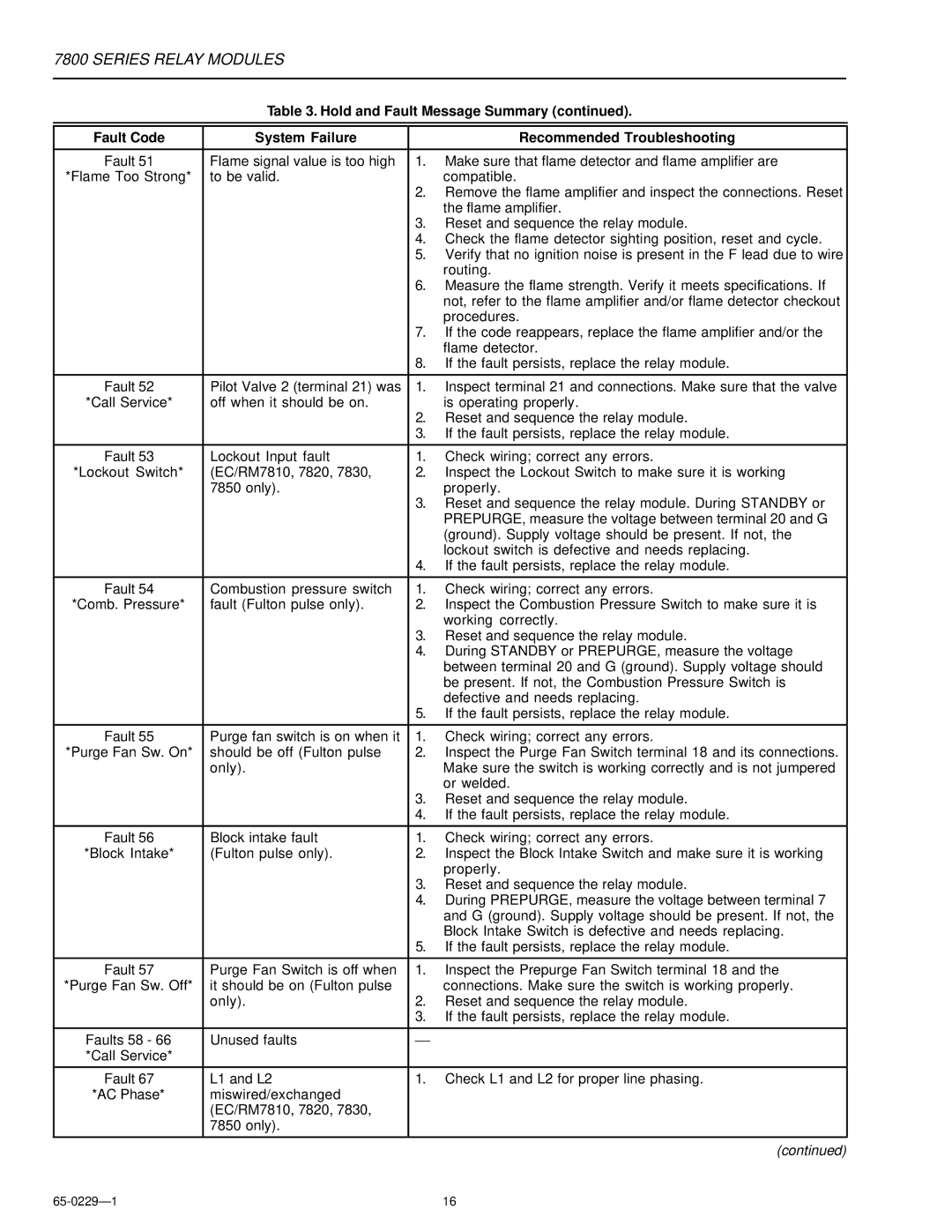

Table 3. Hold and Fault Message Summary (continued).

Fault Code | System Failure |

| Recommended Troubleshooting |

|

|

|

|

Fault 51 | Flame signal value is too high | 1. | Make sure that flame detector and flame amplifier are |

*Flame Too Strong* | to be valid. |

| compatible. |

|

| 2. | Remove the flame amplifier and inspect the connections. Reset |

|

|

| the flame amplifier. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | Check the flame detector sighting position, reset and cycle. |

|

| 5. | Verify that no ignition noise is present in the F lead due to wire |

|

|

| routing. |

|

| 6. | Measure the flame strength. Verify it meets specifications. If |

|

|

| not, refer to the flame amplifier and/or flame detector checkout |

|

|

| procedures. |

|

| 7. | If the code reappears, replace the flame amplifier and/or the |

|

|

| flame detector. |

|

| 8. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 52 | Pilot Valve 2 (terminal 21) was | 1. | Inspect terminal 21 and connections. Make sure that the valve |

*Call Service* | off when it should be on. |

| is operating properly. |

|

| 2. | Reset and sequence the relay module. |

|

| 3. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 53 | Lockout Input fault | 1. | Check wiring; correct any errors. |

*Lockout Switch* | (EC/RM7810, 7820, 7830, | 2. | Inspect the Lockout Switch to make sure it is working |

| 7850 only). |

| properly. |

|

| 3. | Reset and sequence the relay module. During STANDBY or |

|

|

| PREPURGE, measure the voltage between terminal 20 and G |

|

|

| (ground). Supply voltage should be present. If not, the |

|

|

| lockout switch is defective and needs replacing. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 54 | Combustion pressure switch | 1. | Check wiring; correct any errors. |

*Comb. Pressure* | fault (Fulton pulse only). | 2. | Inspect the Combustion Pressure Switch to make sure it is |

|

|

| working correctly. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | During STANDBY or PREPURGE, measure the voltage |

|

|

| between terminal 20 and G (ground). Supply voltage should |

|

|

| be present. If not, the Combustion Pressure Switch is |

|

|

| defective and needs replacing. |

|

| 5. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 55 | Purge fan switch is on when it | 1. | Check wiring; correct any errors. |

*Purge Fan Sw. On* | should be off (Fulton pulse | 2. | Inspect the Purge Fan Switch terminal 18 and its connections. |

| only). |

| Make sure the switch is working correctly and is not jumpered |

|

|

| or welded. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 56 | Block intake fault | 1. | Check wiring; correct any errors. |

*Block Intake* | (Fulton pulse only). | 2. | Inspect the Block Intake Switch and make sure it is working |

|

|

| properly. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | During PREPURGE, measure the voltage between terminal 7 |

|

|

| and G (ground). Supply voltage should be present. If not, the |

|

|

| Block Intake Switch is defective and needs replacing. |

|

| 5. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 57 | Purge Fan Switch is off when | 1. | Inspect the Prepurge Fan Switch terminal 18 and the |

*Purge Fan Sw. Off* | it should be on (Fulton pulse |

| connections. Make sure the switch is working properly. |

| only). | 2. | Reset and sequence the relay module. |

|

| 3. | If the fault persists, replace the relay module. |

|

|

|

|

Faults 58 - 66 | Unused faults | |

|

*Call Service* |

|

|

|

|

|

|

|

Fault 67 | L1 and L2 | 1. | Check L1 and L2 for proper line phasing. |

*AC Phase* | miswired/exchanged |

|

|

| (EC/RM7810, 7820, 7830, |

|

|

| 7850 only). |

|

|

|

|

|

|

|

|

| (continued) |

16 |