|

|

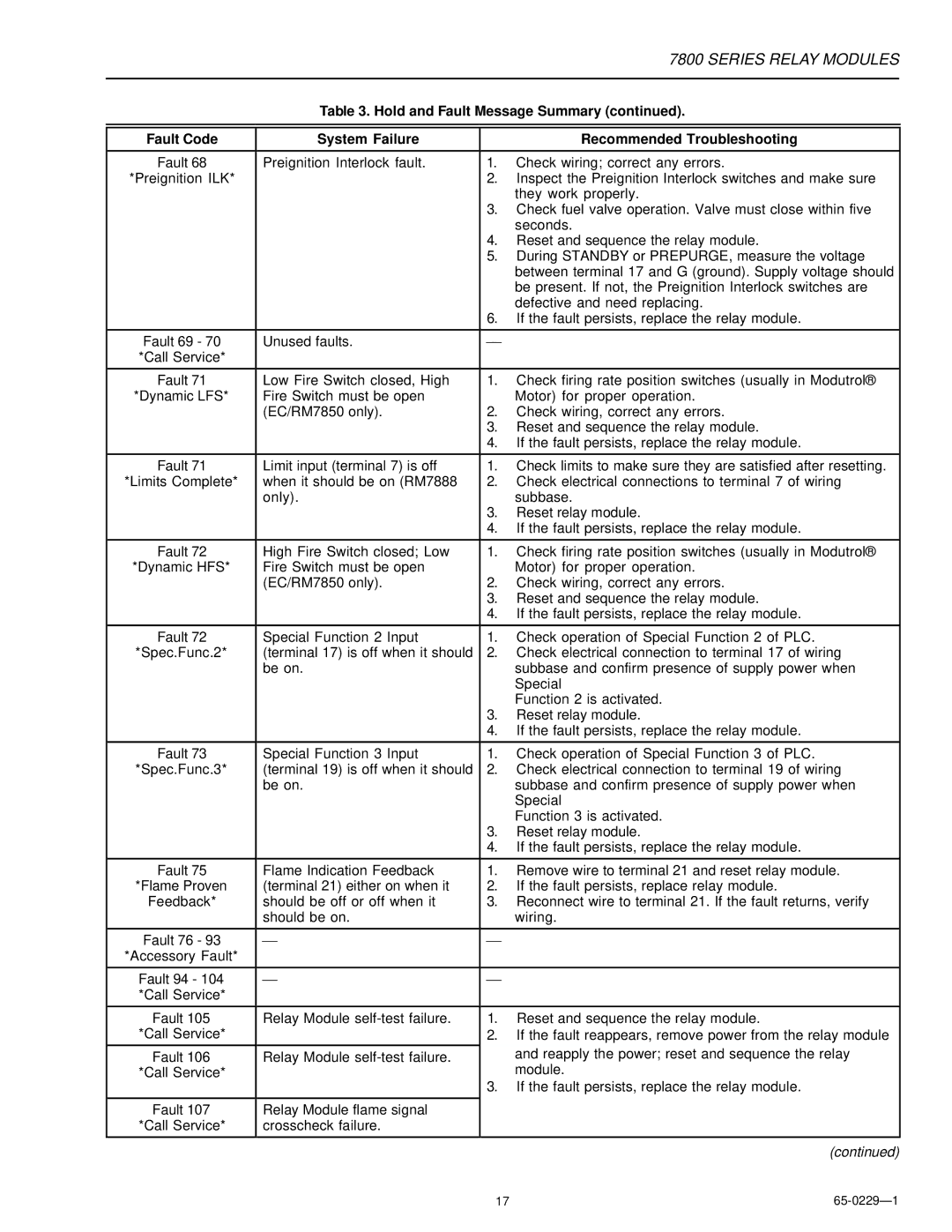

| 7800 SERIES RELAY MODULES |

|

|

| |

| Table 3. Hold and Fault Message Summary (continued). | ||

|

|

|

|

Fault Code | System Failure |

| Recommended Troubleshooting |

|

|

|

|

Fault 68 | Preignition Interlock fault. | 1. | Check wiring; correct any errors. |

*Preignition ILK* |

| 2. | Inspect the Preignition Interlock switches and make sure |

|

|

| they work properly. |

|

| 3. | Check fuel valve operation. Valve must close within five |

|

|

| seconds. |

|

| 4. | Reset and sequence the relay module. |

|

| 5. | During STANDBY or PREPURGE, measure the voltage |

|

|

| between terminal 17 and G (ground). Supply voltage should |

|

|

| be present. If not, the Preignition Interlock switches are |

|

|

| defective and need replacing. |

|

| 6. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 69 - 70 | Unused faults. | |

|

*Call Service* |

|

|

|

|

|

|

|

Fault 71 | Low Fire Switch closed, High | 1. | Check firing rate position switches (usually in Modutrol® |

*Dynamic LFS* | Fire Switch must be open |

| Motor) for proper operation. |

| (EC/RM7850 only). | 2. | Check wiring, correct any errors. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 71 | Limit input (terminal 7) is off | 1. | Check limits to make sure they are satisfied after resetting. |

*Limits Complete* | when it should be on (RM7888 | 2. | Check electrical connections to terminal 7 of wiring |

| only). |

| subbase. |

|

| 3. | Reset relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 72 | High Fire Switch closed; Low | 1. | Check firing rate position switches (usually in Modutrol® |

*Dynamic HFS* | Fire Switch must be open |

| Motor) for proper operation. |

| (EC/RM7850 only). | 2. | Check wiring, correct any errors. |

|

| 3. | Reset and sequence the relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 72 | Special Function 2 Input | 1. | Check operation of Special Function 2 of PLC. |

*Spec.Func.2* | (terminal 17) is off when it should | 2. | Check electrical connection to terminal 17 of wiring |

| be on. |

| subbase and confirm presence of supply power when |

|

|

| Special |

|

|

| Function 2 is activated. |

|

| 3. | Reset relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 73 | Special Function 3 Input | 1. | Check operation of Special Function 3 of PLC. |

*Spec.Func.3* | (terminal 19) is off when it should | 2. | Check electrical connection to terminal 19 of wiring |

| be on. |

| subbase and confirm presence of supply power when |

|

|

| Special |

|

|

| Function 3 is activated. |

|

| 3. | Reset relay module. |

|

| 4. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 75 | Flame Indication Feedback | 1. | Remove wire to terminal 21 and reset relay module. |

*Flame Proven | (terminal 21) either on when it | 2. | If the fault persists, replace relay module. |

Feedback* | should be off or off when it | 3. | Reconnect wire to terminal 21. If the fault returns, verify |

| should be on. |

| wiring. |

|

|

|

|

Fault 76 - 93 | | |

|

*Accessory Fault* |

|

|

|

|

|

|

|

Fault 94 - 104 | | |

|

*Call Service* |

|

|

|

|

|

|

|

Fault 105 | Relay Module | 1. | Reset and sequence the relay module. |

*Call Service* |

| 2. | If the fault reappears, remove power from the relay module |

Fault 106 | Relay Module |

| and reapply the power; reset and sequence the relay |

*Call Service* |

|

| module. |

|

| 3. | If the fault persists, replace the relay module. |

|

|

|

|

Fault 107 | Relay Module flame signal |

|

|

*Call Service* | crosscheck failure. |

|

|

|

|

|

|

(continued)

17 |