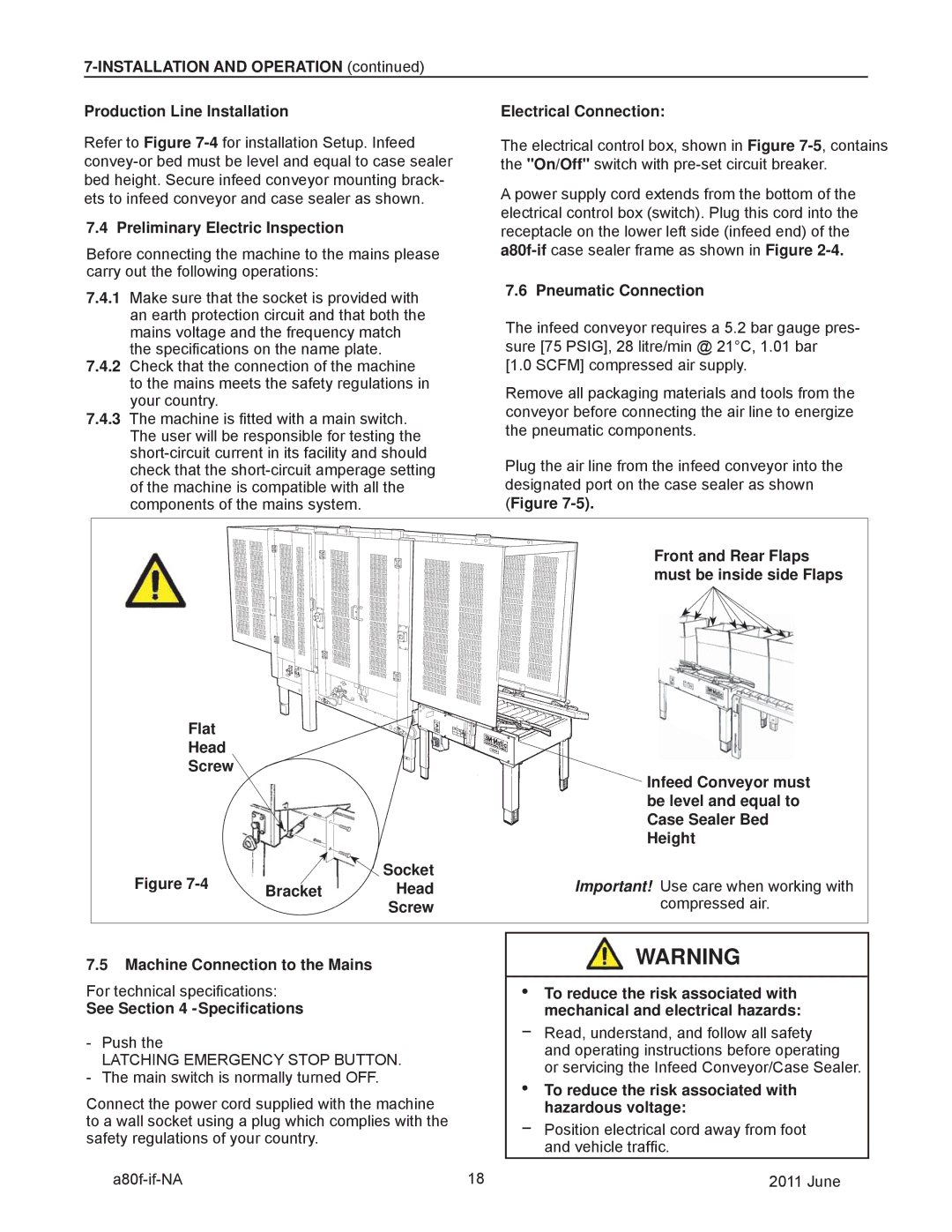

Production Line Installation | Electrical Connection: | |||||||

Refer to Figure | The electrical control box, shown in Figure | |||||||

the "On/Off" switch with | ||||||||

bed height. Secure infeed conveyor mounting brack- | A power supply cord extends from the bottom of the | |||||||

ets to infeed conveyor and case sealer as shown. | ||||||||

7.4 Preliminary Electric Inspection | electrical control box (switch). Plug this cord into the | |||||||

receptacle on the lower left side (infeed end) of the | ||||||||

Before connecting the machine to the mains please | ||||||||

carry out the following operations: | 7.6 Pneumatic Connection | |||||||

7.4.1 | Make sure that the socket is provided with | |||||||

|

|

|

| |||||

|

| an earth protection circuit and that both the | The infeed conveyor requires a 5.2 bar gauge pres- | |||||

|

| mains voltage and the frequency match | ||||||

7.4.2 | the specifications on the name plate. | sure [75 PSIG], 28 litre/min @ 21°C, 1.01 bar | ||||||

Check that the connection of the machine | [1.0 SCFM] compressed air supply. | |||||||

|

| to the mains meets the safety regulations in | Remove all packaging materials and tools from the | |||||

|

| your country. | ||||||

7.4.3 | conveyor before connecting the air line to energize | |||||||

The machine is fitted with a main switch. | ||||||||

the pneumatic components. | ||||||||

|

| The user will be responsible for testing the | ||||||

|

| Plug the air line from the infeed conveyor into the | ||||||

|

| check that the | ||||||

|

| of the machine is compatible with all the | designated port on the case sealer as shown | |||||

|

| components of the mains system. | (Figure |

| ||||

|

|

|

|

|

|

| ||

|

|

|

|

| Front and Rear Flaps | |||

|

|

|

|

|

|

| ||

|

|

|

|

| must be inside side Flaps |

| ||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

Flat

Head

Screw

Infeed Conveyor must

be level and equal to

Case Sealer Bed

Height

|

|

|

| Socket |

| |

Figure |

|

|

| Important! Use care when working with | ||

|

|

| Head | |||

| Bracket | |||||

| ||||||

|

|

|

| Screw | compressed air. | |

|

|

|

| |||

|

|

|

|

|

|

7.5Machine Connection to the Mains

For technical specifications:

See Section 4 -Specifications

-Push the

LATCHING EMERGENCY STOP BUTTON.

-The main switch is normally turned OFF.

Connect the power cord supplied with the machine to a wall socket using a plug which complies with the safety regulations of your country.

18 |

![]() WARNING

WARNING

•To reduce the risk associated with mechanical and electrical hazards:

−Read, understand, and follow all safety and operating instructions before operating

or servicing the Infeed Conveyor/Case Sealer.

•To reduce the risk associated with hazardous voltage:

−Position electrical cord away from foot and vehicle traffic.

2011 June